cnc lathe parts aluminum cnc machined aluminum parts

CNC Lathe Parts

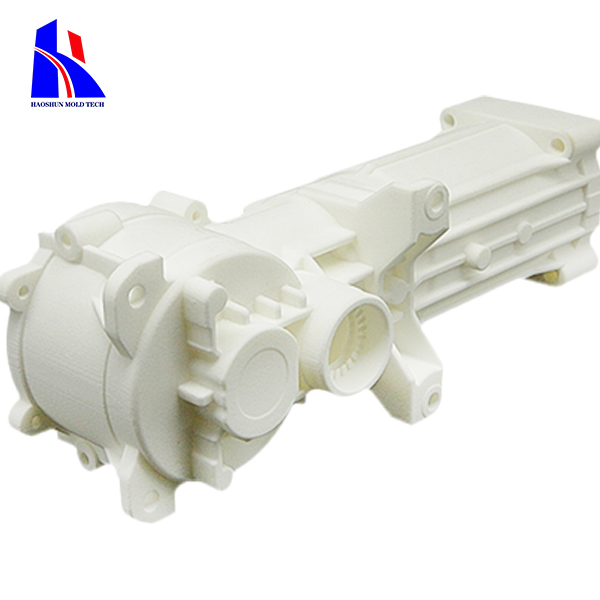

1.Definition: CNC lathes are machines that use computer numerical control (CNC) to automate the process of shaping metal or other materials with a cutting tool. This process is known as turning and is used to create cylindrical parts.

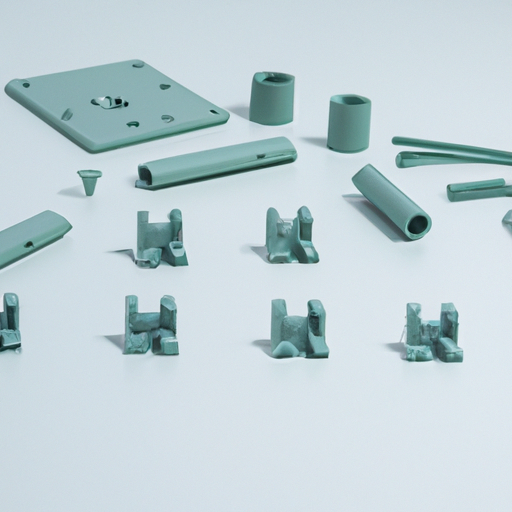

2.Materials: CNC lathe parts can be made from various materials including aluminum, steel, brass, and plastics. Aluminum is popular due to its lightweight, corrosion resistance, and machinability.

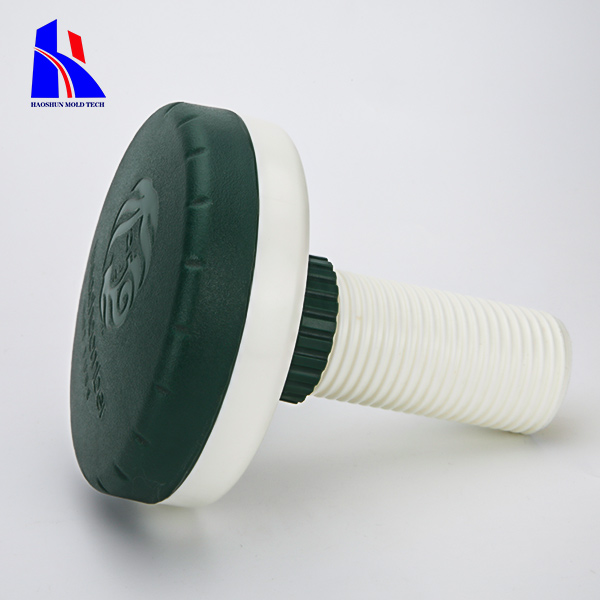

3.Applications: CNC lathe parts are used in industries such as aerospace, automotive, electronics, and medical devices. Common components include shafts, bushings, connectors, and fittings.

4.Advantages: Precision and repeatability are key advantages of CNC lathe machining. It allows for complex geometries and tight tolerances to be achieved consistently.

CNC Machined Aluminum Parts

5.Definition: CNC machining involves using computer-controlled machines to remove material from a workpiece to create a custom-designed part. Aluminum is a widely used material due to its strength-to-weight ratio, corrosion resistance, and machinability.

6.Processes: CNC machining processes for aluminum parts include milling, turning (using a lathe), drilling, tapping, and threading. Each process can achieve different geometries and surface finishes.

7.Applications: Machined aluminum parts are used in industries ranging from automotive and aerospace to consumer electronics and medical devices. Examples include brackets, enclosures, heat sinks, and custom fittings.

8.Advantages: CNC machining offers versatility in design, allowing for complex shapes and precise dimensions. Aluminum’s properties make it suitable for both functional and aesthetic components.

Finding Manufacturers

To find manufacturers specializing in CNC lathe parts or CNC machined aluminum parts:

9.Search Online: Use search engines with specific keywords like “CNC lathe parts manufacturer” or “aluminum CNC machining services.”

10.Industry Directories: Websites like ThomasNet, Alibaba, or MFG.com provide listings and detailed profiles of manufacturers.

11.Local Directories and Associations: Check local business directories or industry associations for manufacturers in your area.

12.Trade Shows and Exhibitions: Attend events focused on manufacturing to meet potential suppliers and see their capabilities.

13.Referrals: Ask colleagues or industry contacts for recommendations based on their experiences.

When choosing a manufacturer, consider factors such as their capabilities, quality standards, lead times, and customer service. Request quotes and samples to evaluate their suitability for your specific needs.

Email: shine@haoshun_tech_com

Telephone: +8613560008062