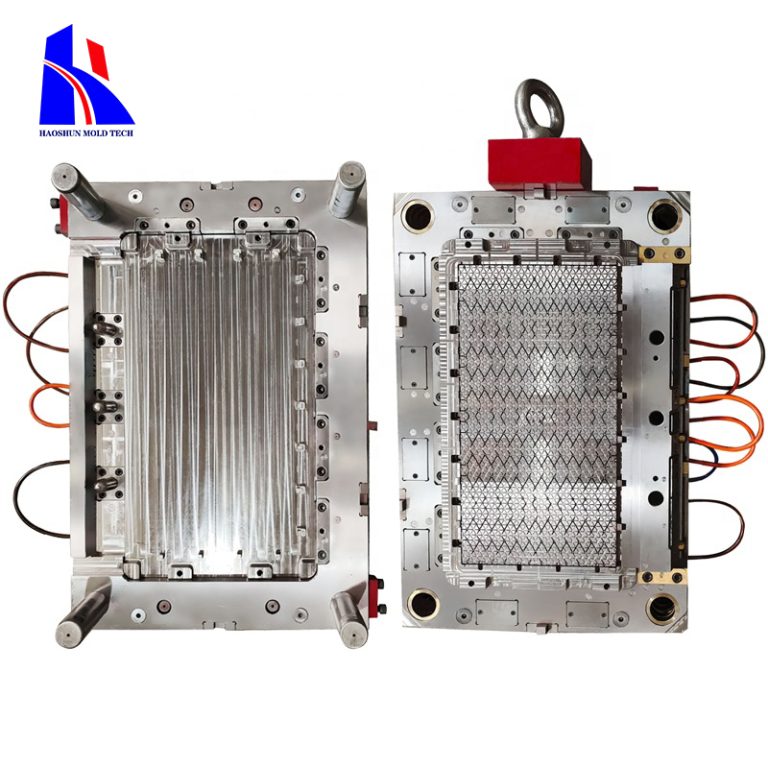

injection molded parts

Benefits of Using Injection Molded Parts in Manufacturing

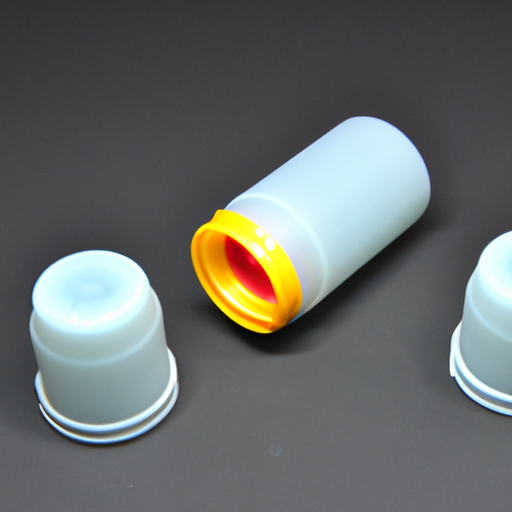

Injection molded parts are a crucial component in the manufacturing industry, offering a wide range of benefits that make them a popular choice for producing various products. From automotive components to medical devices, injection molded parts play a significant role in the production process, providing manufacturers with a cost-effective and efficient solution for creating high-quality products.

One of the key benefits of using injection molded parts is their versatility. These parts can be customized to meet specific design requirements, allowing manufacturers to create complex shapes and intricate details that would be difficult or impossible to achieve with other manufacturing methods. This flexibility makes injection molded parts ideal for a wide range of applications, from consumer electronics to aerospace components.

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

In addition to their versatility, injection molded parts are also highly durable and resistant to wear and tear. This durability makes them an excellent choice for products that need to withstand harsh conditions or frequent use, such as automotive components or industrial equipment. Injection molded parts are also lightweight, which can help reduce shipping costs and make products easier to handle and assemble.

Another benefit of using injection molded parts is their cost-effectiveness. The injection molding process is highly efficient, allowing manufacturers to produce large quantities of parts quickly and at a relatively low cost. This efficiency can help companies save money on production costs and increase their profit margins, making injection molded parts a cost-effective solution for mass production.

Furthermore, injection molded parts are produced with minimal waste, making them an environmentally friendly option for manufacturers. The injection molding process generates very little scrap material, and any excess plastic can be recycled and reused in future production runs. This sustainability makes injection molded parts a popular choice for companies looking to reduce their environmental impact and operate more responsibly.

In addition to their environmental benefits, injection molded parts also offer excellent precision and consistency. The injection molding process allows for tight tolerances and high levels of accuracy, ensuring that each part meets the exact specifications required for the final product. This precision can help manufacturers avoid costly errors and rework, saving time and money in the production process.

Overall, injection molded parts offer a wide range of benefits that make them an attractive option for manufacturers across various industries. From their versatility and durability to their cost-effectiveness and sustainability, injection molded parts provide a reliable and efficient solution for producing high-quality products. Whether you’re looking to create complex shapes, reduce production costs, or minimize waste, injection molded parts can help you achieve your manufacturing goals with ease.