mini injection molding make plastic small

Benefits of Mini Injection Molding for Small Plastic Parts

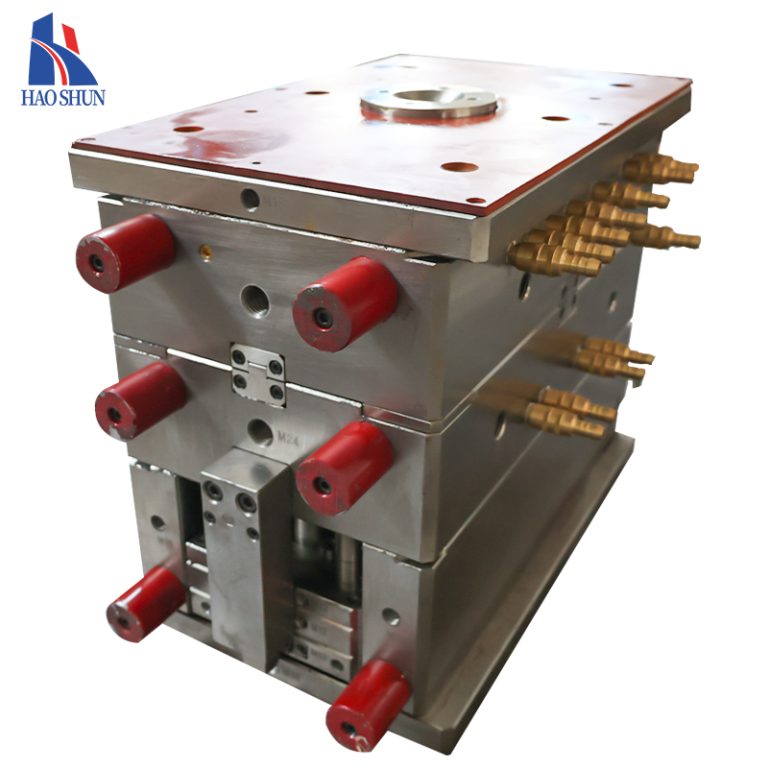

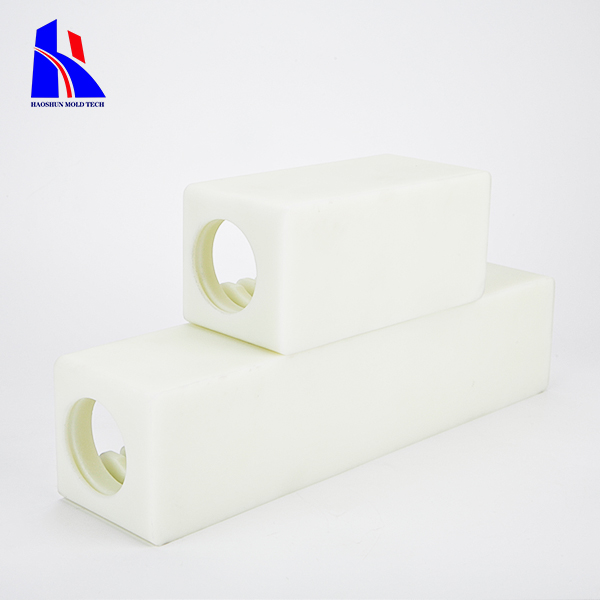

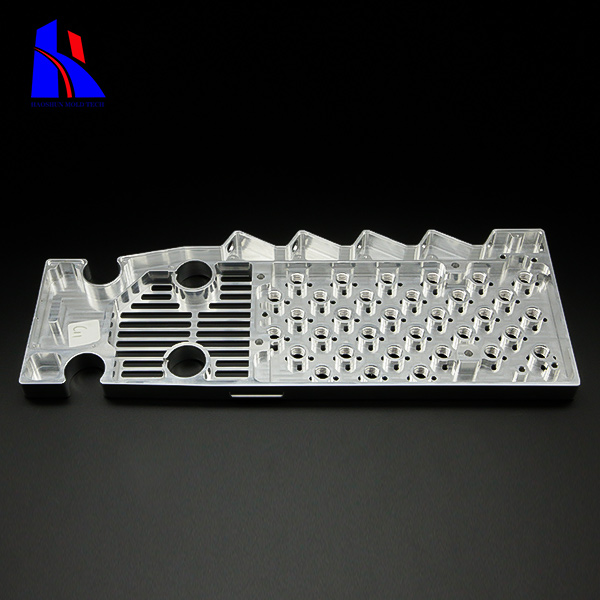

Mini injection molding is a process that has revolutionized the production of small plastic parts. This technology allows for the creation of intricate and precise components that are essential in a wide range of industries. From medical devices to electronics, mini injection molding offers numerous benefits for manufacturers looking to produce small plastic parts efficiently and cost-effectively.

One of the key advantages of mini injection molding is its ability to produce high-quality parts with tight tolerances. This is crucial for industries where precision is paramount, such as the medical and aerospace sectors. Mini injection molding machines are capable of producing parts with extremely fine details, ensuring that each component meets the exact specifications required.

In addition to precision, mini injection molding also offers a high level of repeatability. This means that manufacturers can produce large quantities of identical parts with minimal variation. This is essential for industries that require consistency in their products, such as the automotive and consumer goods sectors. Mini injection molding machines can run continuously, producing parts at a rapid pace without sacrificing quality.

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Our Services | OEM/ODM |

Another benefit of mini injection molding is its cost-effectiveness. Traditional injection molding machines are often large and expensive, making them impractical for small-scale production. Mini injection molding machines, on the other hand, are compact and affordable, making them ideal for small batch production runs. This allows manufacturers to produce small plastic parts without the need for large capital investments.

Mini injection molding also offers a faster turnaround time compared to traditional molding methods. The compact size of mini injection molding machines allows for quicker setup and production times, reducing lead times and getting products to market faster. This is crucial for industries where time-to-market is a critical factor in success.

Furthermore, mini injection molding is environmentally friendly. The process generates minimal waste, as any excess material can be recycled and reused. This not only reduces the environmental impact of production but also helps manufacturers save on material costs. Additionally, mini injection molding machines are energy-efficient, consuming less power than traditional molding machines.

Overall, mini injection molding offers numerous benefits for manufacturers looking to produce small plastic parts. From precision and repeatability to cost-effectiveness and environmental sustainability, mini injection molding is a versatile and efficient technology that is essential for a wide range of industries. By investing in mini injection molding, manufacturers can streamline their production processes, reduce costs, and produce high-quality parts that meet the exact specifications required.