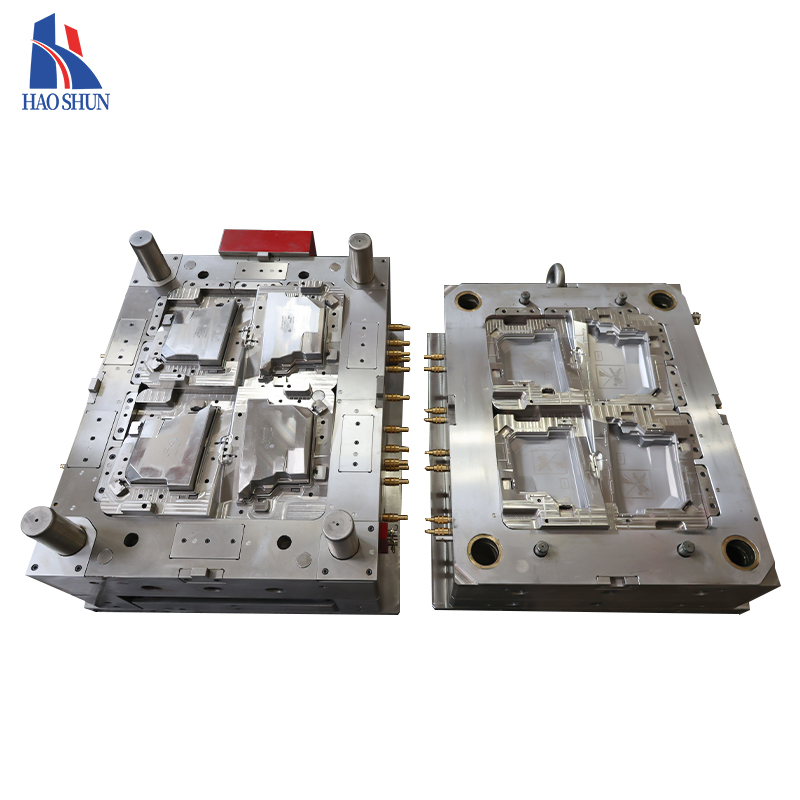

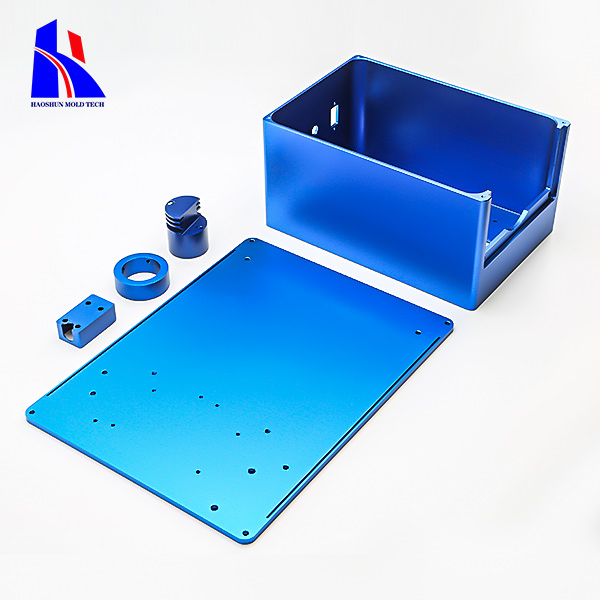

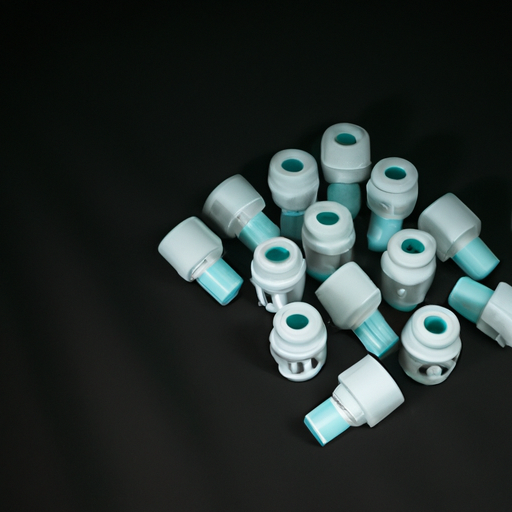

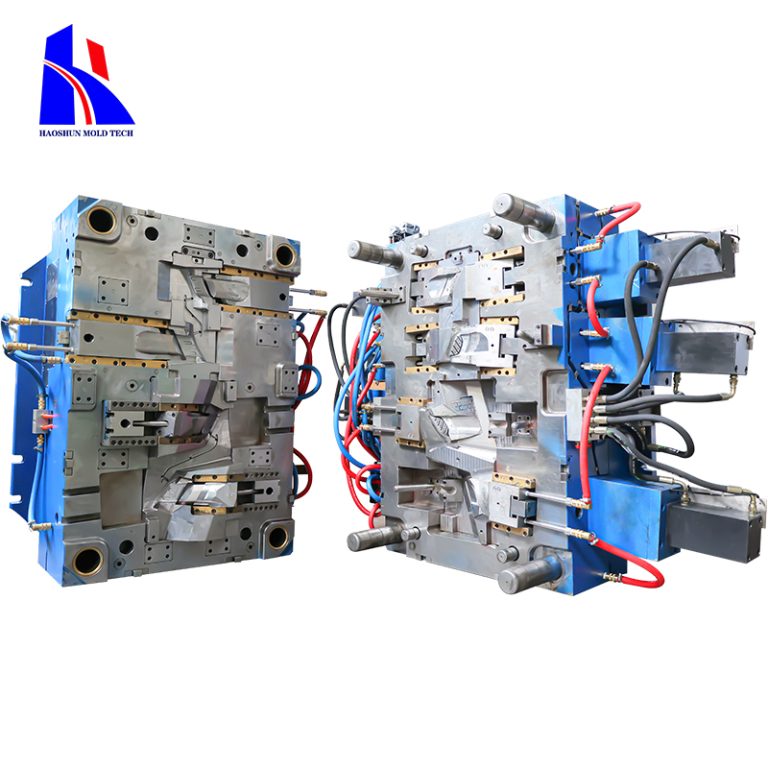

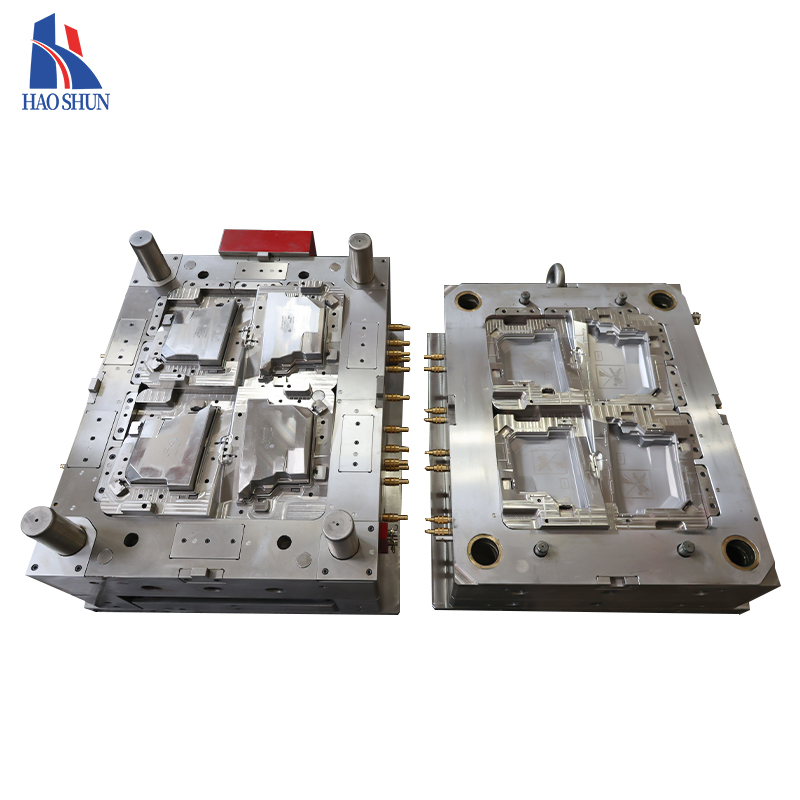

precision mold components

The Benefits of Using Precision Mold Components in Manufacturing

The use of precision mold components in manufacturing offers a number of advantages over traditional manufacturing methods. Precision mold components are designed to provide a high degree of accuracy and repeatability, allowing for the production of parts with consistent dimensions and quality. This can result in improved product performance, reduced waste, and increased efficiency.

| Product name | Plastic Injection Mould |

| Mould Base | SD,LKM Standard, HASCO Standard Self-made, etc. |

Compared to traditional manufacturing methods, precision mold components offer greater accuracy and repeatability. This is due to the fact that the components are designed to exact specifications, allowing for the production of parts with consistent dimensions and quality. This can result in improved product performance, as parts that are produced with greater accuracy and repeatability are more likely to function as intended. Additionally, precision mold components can reduce waste, as they are designed to produce parts with minimal material waste. This can lead to cost savings, as less material is required to produce the same number of parts.

In addition to improved accuracy and repeatability, precision mold components can also increase efficiency. This is because the components are designed to be used multiple times, allowing for the production of multiple parts in a single cycle. This can reduce the amount of time required to produce a given number of parts, resulting in increased efficiency.

Overall, the use of precision mold components in manufacturing offers a number of advantages over traditional manufacturing methods. These components are designed to provide a high degree of accuracy and repeatability, allowing for the production of parts with consistent dimensions and quality. This can result in improved product performance, reduced waste, and increased efficiency.