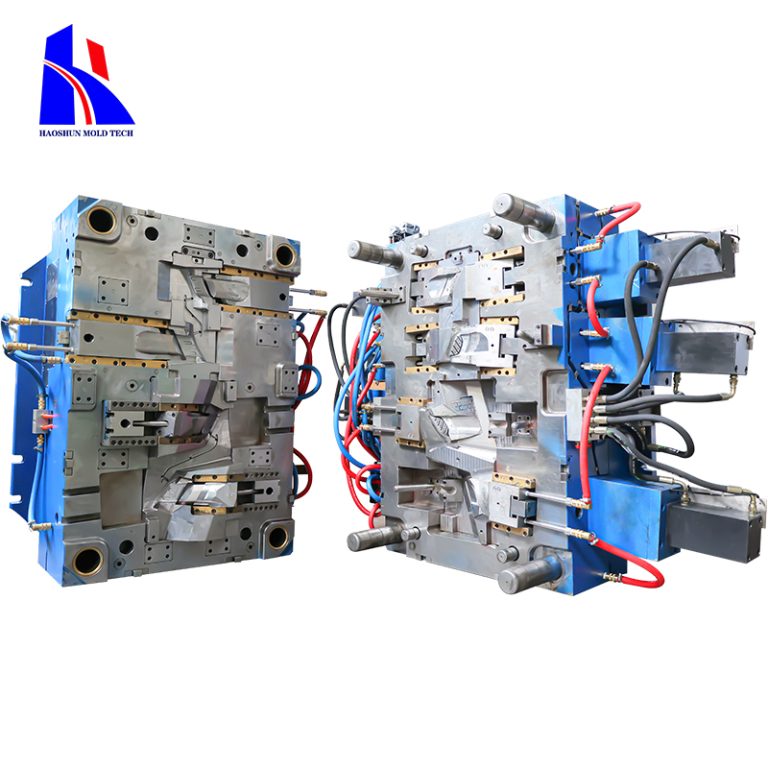

wheat straw injection plastic molding mold

Table of Contents

Benefits of Using Wheat Straw Injection Plastic Molding Mold

Wheat straw injection plastic molding mold is a sustainable and eco-friendly alternative to traditional plastic molds. By using wheat straw as a raw material, manufacturers can reduce their carbon footprint and contribute to a more sustainable future. In this article, we will explore the benefits of using wheat straw injection plastic molding mold and why it is becoming increasingly popular in the manufacturing industry.

One of the key benefits of using wheat straw injection plastic molding mold is its environmental impact. Wheat straw is a renewable resource that is readily available and biodegradable. By using wheat straw as a raw material, manufacturers can reduce their reliance on fossil fuels and decrease the amount of plastic waste that ends up in landfills. This not only helps to protect the environment but also reduces the carbon emissions associated with traditional plastic manufacturing processes.

In addition to its environmental benefits, wheat straw injection plastic molding mold also offers economic advantages. Wheat straw is a cost-effective raw material that is often cheaper than traditional plastics. This can help manufacturers reduce their production costs and increase their profit margins. Furthermore, using wheat straw injection plastic molding mold can help companies attract environmentally conscious consumers who are willing to pay a premium for sustainable products.

Another benefit of using wheat straw injection plastic molding mold is its versatility. Wheat straw can be easily molded into a variety of shapes and sizes, making it ideal for a wide range of applications. From packaging to automotive parts, wheat straw injection plastic molding mold can be used to create durable and high-quality products that meet the needs of consumers. Additionally, wheat straw injection plastic molding mold can be customized to meet specific design requirements, allowing manufacturers to create unique and innovative products that stand out in the market.

Furthermore, wheat straw injection plastic molding mold is easy to work with and requires minimal maintenance. Unlike traditional plastic molds, wheat straw injection plastic molding mold does not require special handling or storage conditions. This makes it a convenient and practical option for manufacturers who are looking to streamline their production processes and increase efficiency. Additionally, wheat straw injection plastic molding mold is durable and long-lasting, ensuring that it can withstand the rigors of daily use without compromising on quality.

Overall, wheat straw injection plastic molding mold offers a sustainable, cost-effective, versatile, and easy-to-use alternative to traditional plastic molds. By using wheat straw as a raw material, manufacturers can reduce their environmental impact, lower their production costs, and create high-quality products that meet the needs of consumers. As the demand for sustainable products continues to grow, wheat straw injection plastic molding mold is poised to become a popular choice for manufacturers looking to make a positive impact on the environment and their bottom line.

Sustainable Practices in Manufacturing with Wheat Straw Injection Plastic Molding Mold

Sustainable Practices in Manufacturing with Wheat Straw Injection Plastic Molding Mold

In recent years, there has been a growing emphasis on sustainability in manufacturing processes. Companies are increasingly looking for ways to reduce their environmental impact and operate in a more eco-friendly manner. One innovative solution that has gained traction in the industry is the use of wheat straw injection plastic molding mold.

Wheat straw injection plastic molding mold is a process that involves using wheat straw, a byproduct of wheat production, as a filler material in plastic injection molding. This process not only helps to reduce the amount of plastic used in manufacturing but also provides a sustainable alternative to traditional plastic fillers.

One of the key benefits of using wheat straw injection plastic molding mold is its environmental impact. By using a renewable and biodegradable material like wheat straw, companies can significantly reduce their carbon footprint and decrease their reliance on non-renewable resources. This is especially important in today’s world, where climate change and environmental degradation are major concerns.

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

Additionally, wheat straw injection plastic molding mold can help companies reduce their waste production. By using a byproduct like wheat straw as a filler material, manufacturers can effectively repurpose materials that would otherwise be discarded. This not only helps to reduce landfill waste but also contributes to a more circular economy where resources are used more efficiently.

Furthermore, wheat straw injection plastic molding mold can also lead to cost savings for companies. Wheat straw is a relatively inexpensive material compared to traditional plastic fillers, which can help to lower production costs. Additionally, using wheat straw as a filler material can improve the mechanical properties of the plastic, making it more durable and long-lasting.

Despite its many benefits, there are some challenges associated with wheat straw injection plastic molding mold. One of the main challenges is ensuring the quality and consistency of the final product. Wheat straw can vary in composition and quality, which can affect the properties of the plastic. Manufacturers need to carefully control the processing parameters to ensure that the final product meets the required specifications.

Another challenge is the limited availability of wheat straw. While wheat straw is a byproduct of wheat production, its availability can be limited depending on the region and the time of year. Companies may need to work closely with farmers and suppliers to ensure a steady supply of wheat straw for their manufacturing processes.

In conclusion, wheat straw injection plastic molding mold is a sustainable practice that offers numerous benefits for companies looking to reduce their environmental impact and operate more sustainably. By using wheat straw as a filler material in plastic injection molding, companies can lower their carbon footprint, reduce waste production, and potentially save on production costs. While there are challenges associated with this process, with careful planning and management, companies can successfully implement wheat straw injection plastic molding mold in their manufacturing processes.