auto parts molds

Table of Contents

The Benefits of Using Auto Parts Molds for Automotive Manufacturing

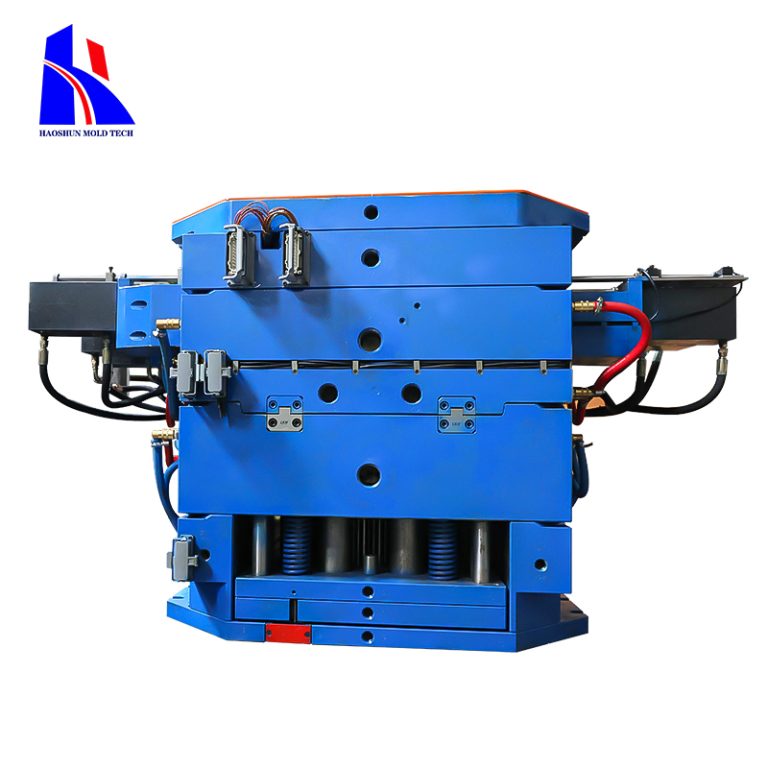

Auto parts molds are an essential tool for automotive manufacturing. They provide a cost-effective and efficient way to produce high-quality parts for cars, trucks, and other vehicles. By using molds, manufacturers can produce parts quickly and accurately, reducing the time and cost associated with traditional manufacturing methods.

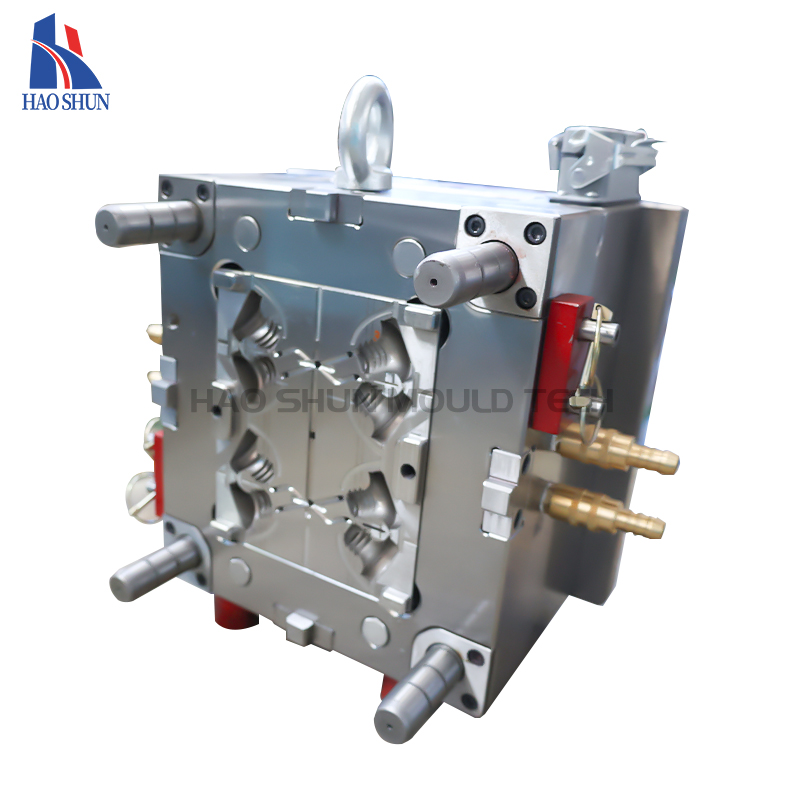

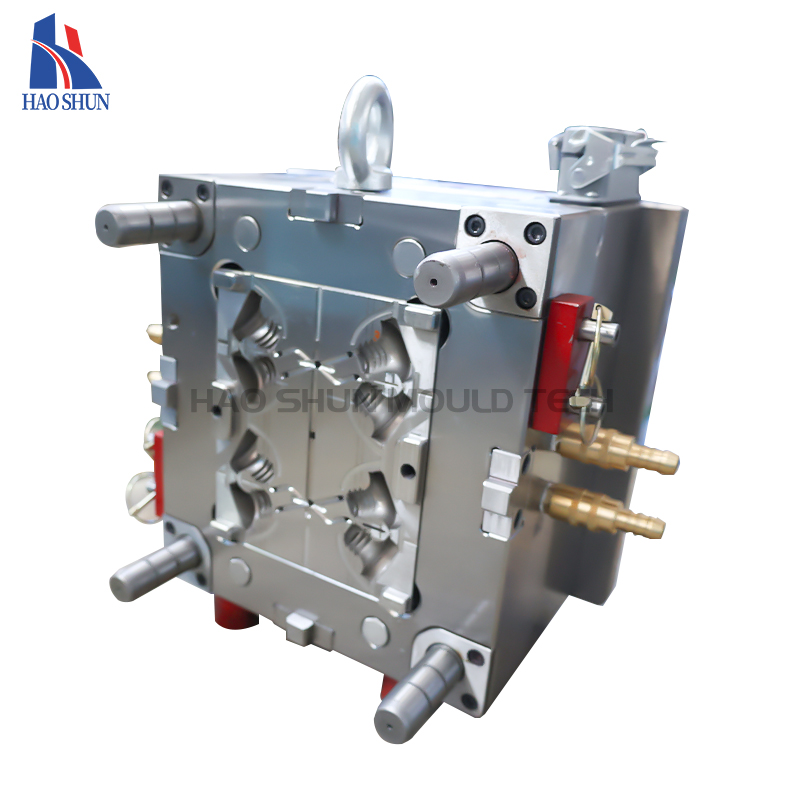

Auto parts molds are made from durable materials such as aluminum, steel, and plastic. This ensures that the parts produced are of the highest quality and can withstand the rigors of everyday use. The molds are designed to be precise and accurate, allowing for a consistent product every time. This helps to reduce the amount of time and money spent on production, as well as the number of defects that can occur.

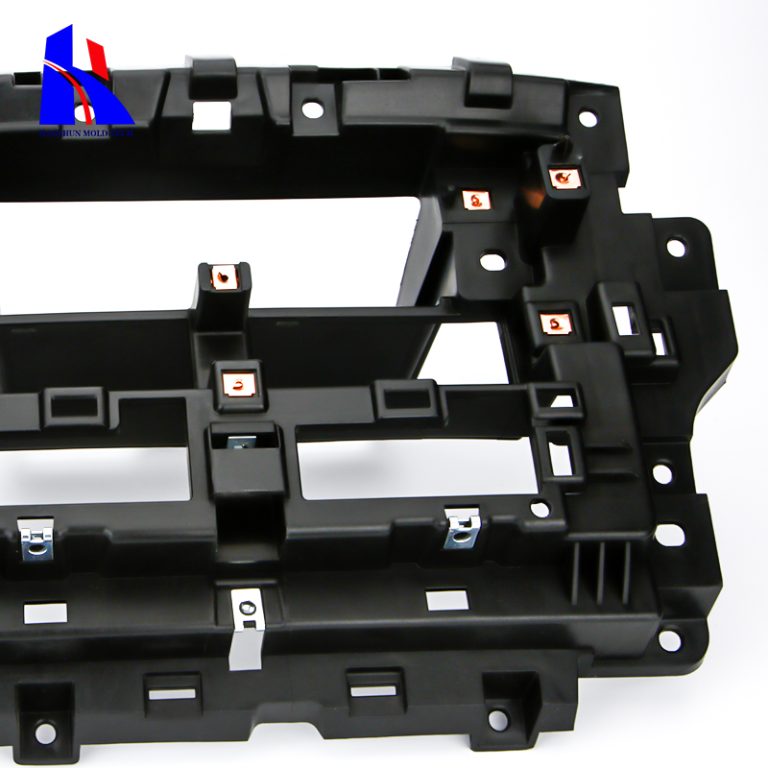

Using auto parts molds also helps to reduce waste. By using molds, manufacturers can produce parts with minimal waste, as the molds are designed to produce parts that are the exact size and shape needed. This helps to reduce the amount of material that is wasted during the manufacturing process.

Auto parts molds also help to reduce the amount of labor required for production. By using molds, manufacturers can produce parts quickly and accurately, reducing the amount of time and money spent on labor. This helps to reduce the overall cost of production, as well as the amount of time it takes to produce a part.

| Mould Life | 50-500K shots |

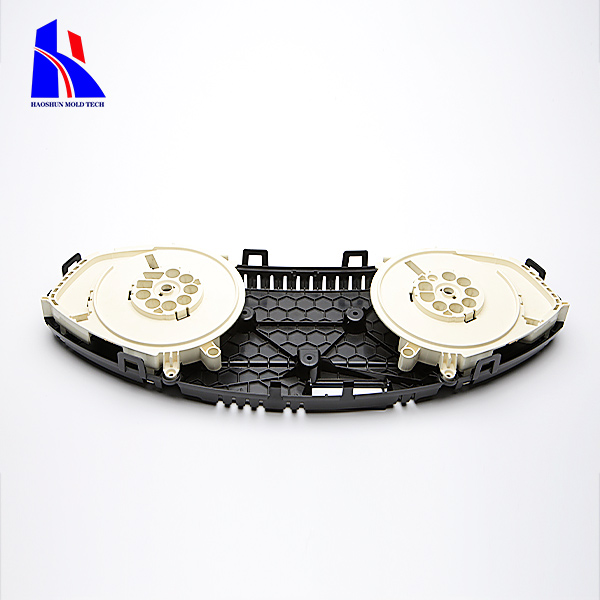

| Mould Cavity | Single cavity, multi-cavities |

| Runner System | Hot runner and cold runner |

Finally, auto parts molds are a great way to ensure that parts are produced with the highest quality. By using molds, manufacturers can produce parts that are consistent in size and shape, ensuring that they meet the highest standards of quality. This helps to ensure that the parts produced are reliable and durable, providing customers with a product that will last for years to come.

Overall, auto parts molds are an essential tool for automotive manufacturing. They provide a cost-effective and efficient way to produce high-quality parts quickly and accurately, reducing the time and cost associated with traditional manufacturing methods. By using molds, manufacturers can produce parts with minimal waste, reduce the amount of labor required for production, and ensure that parts are produced with the highest quality. This helps to ensure that customers receive a reliable and durable product that will last for years to come.

Exploring the Latest Innovations in Auto Parts Molds Technology

The auto parts industry is constantly evolving, and the latest innovations in auto parts molds technology are revolutionizing the way car parts are made. From the traditional metal molds to the latest 3D printing technology, auto parts molds are becoming more efficient and cost-effective.

The traditional metal molds are still widely used in the auto parts industry, but they are becoming increasingly outdated. Metal molds are expensive to produce and require a lot of manual labor to create. They also require a lot of time and energy to maintain, as they are prone to wear and tear.

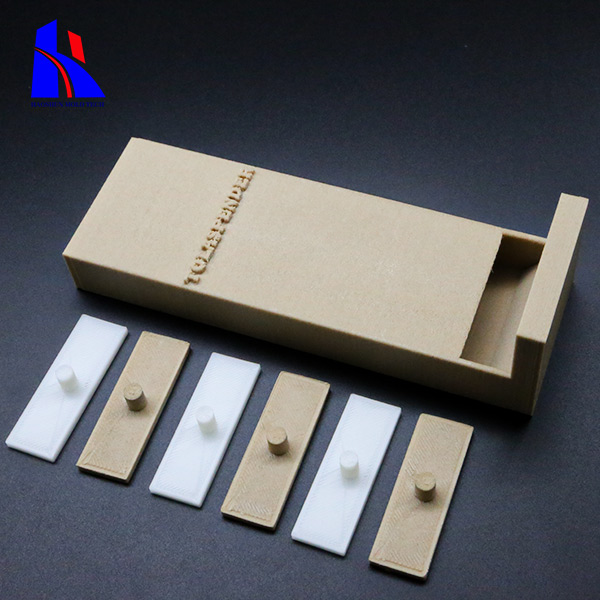

The latest innovation in auto parts molds technology is 3D printing. This technology uses a computer-controlled printer to create a three-dimensional object from a digital file. This technology is much faster and more cost-effective than traditional metal molds, and it can produce complex shapes and intricate details that would be impossible to create with metal molds.

3D printing is also much more efficient than traditional metal molds. It can produce parts in a fraction of the time and with much less waste. This technology is also much more precise, allowing for parts to be made with exact specifications.

The latest innovations in auto parts molds technology are revolutionizing the way car parts are made. From the traditional metal molds to the latest 3D printing technology, auto parts molds are becoming more efficient and cost-effective. This technology is allowing for faster production times, more precise parts, and less waste. It is an exciting time for the auto parts industry, and these innovations are sure to have a lasting impact.