injection molding for chair plastic stool

Benefits of Injection Molding for Producing Plastic Chairs and Stools

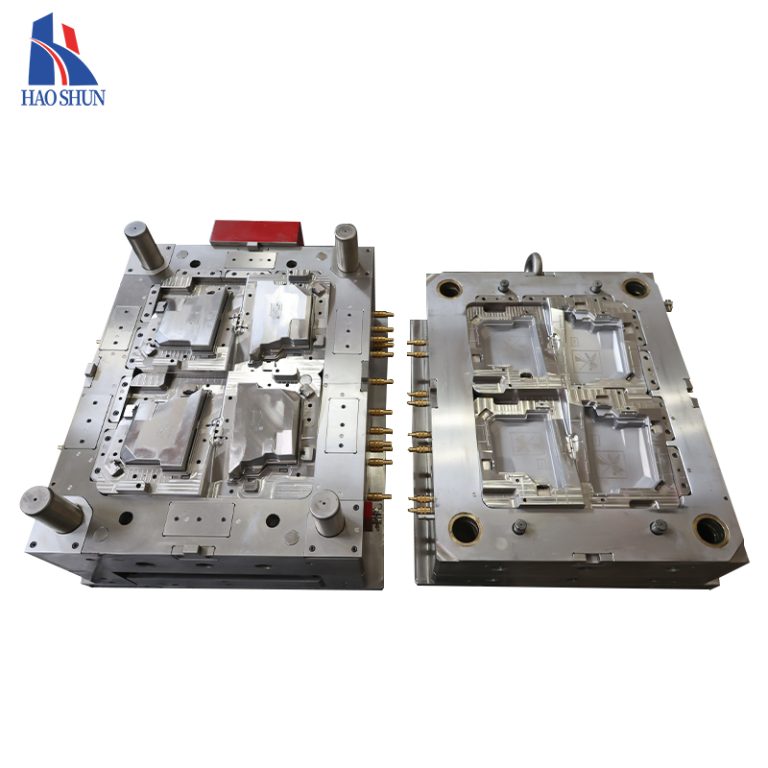

Injection molding is a widely used manufacturing process for producing plastic chairs and stools. This method involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. Injection molding offers several benefits for producing plastic chairs and stools, making it a popular choice for manufacturers in the furniture industry.

One of the key advantages of injection molding is its ability to produce high volumes of plastic chairs and stools quickly and efficiently. The process is highly automated, allowing for continuous production with minimal downtime. This makes injection molding ideal for mass production, where large quantities of identical products are required.

In addition to high production speeds, injection molding also offers excellent precision and consistency in the final product. The molds used in the process are designed to exact specifications, ensuring that each chair or stool is produced with consistent dimensions and quality. This level of precision is essential for ensuring that all products meet the required standards and specifications.

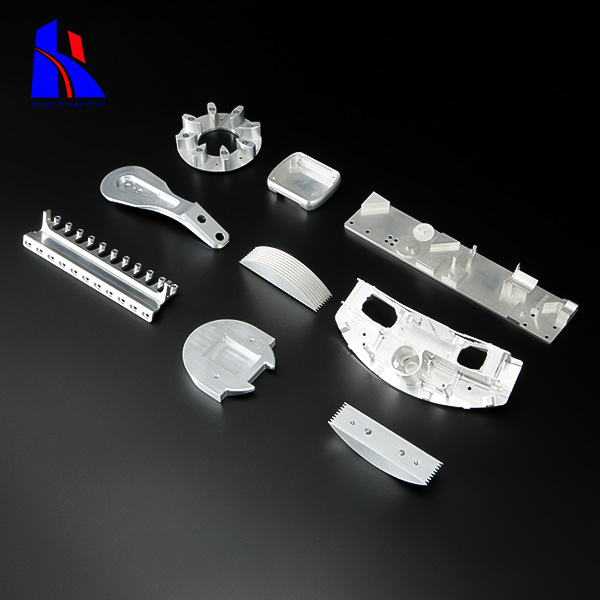

Another benefit of injection molding is its versatility in design. The process allows for complex shapes and intricate details to be easily incorporated into the final product. This flexibility in design is particularly advantageous for producing chairs and stools with unique features or ergonomic considerations. Manufacturers can easily customize the mold to create chairs and stools that meet specific requirements and preferences.

Injection molding also offers cost savings for manufacturers producing plastic chairs and stools. The process is highly efficient, with minimal material waste and reduced labor costs compared to other manufacturing methods. This results in lower production costs, making injection molding a cost-effective solution for producing plastic furniture.

Furthermore, injection molding is a sustainable manufacturing process for producing plastic chairs and stools. The molds used in the process are typically made from durable materials such as steel or aluminum, which can be reused multiple times. This reduces the need for new molds to be created for each production run, minimizing waste and environmental impact.

Additionally, many plastic materials used in injection molding are recyclable, further reducing the environmental footprint of the manufacturing process. By using recycled materials and optimizing production efficiency, manufacturers can minimize their impact on the environment while still producing high-quality plastic chairs and stools.

| Product Name | OEM Plastic injection molding Parts |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

Overall, injection molding offers numerous benefits for producing plastic chairs and stools. From high production speeds and precision to design flexibility and cost savings, this manufacturing process is a popular choice for manufacturers in the furniture industry. With its sustainable practices and ability to produce high-quality products, injection molding is a reliable and efficient method for creating plastic furniture that meets the demands of today’s market.