rapid prototype making tools

Table of Contents

Exploring the Benefits of Rapid Prototype Making Tools for Product Designers

Product designers are always looking for ways to make their work easier and more efficient. Rapid prototype making tools are one of the most useful tools available to them. These tools allow designers to quickly create prototypes of their designs, allowing them to test and refine their ideas before committing to a final product.

The benefits of rapid prototype making tools are numerous. First, they allow designers to quickly create a prototype of their design. This allows them to test and refine their ideas before committing to a final product. This saves time and money, as designers can quickly identify any issues with their design before investing in costly production.

Second, rapid prototype making tools allow designers to create a physical representation of their design. This allows them to get a better understanding of how their design will look and feel in the real world. This can help them to make more informed decisions about their design and ensure that it meets their expectations.

Third, rapid prototype making tools allow designers to quickly create multiple versions of their design. This allows them to experiment with different ideas and find the best solution for their product. This can save time and money, as designers can quickly identify the best design for their product without having to invest in costly production.

| Production Process | 3D Drawing-3D Max-File Conversion-Slice-Printing-Post Processing-Quality Inspection-Packaging-Shipment |

| Price Comparison | Plastic: FDM<SLA<SLS (PA12<PA12+GF)<MJF<DLP (Blue wax<Red wax) Metal: SLM (Stainless steel<Aluminum alloy<Titanium alloy) |

Finally, rapid prototype making tools allow designers to quickly create prototypes that can be used for marketing purposes. This can help designers to showcase their product to potential customers and investors, allowing them to get feedback on their design before committing to a final product.

Overall, rapid prototype making tools are an invaluable tool for product designers. They allow designers to quickly create prototypes of their designs, test and refine their ideas, create multiple versions of their design, and showcase their product to potential customers and investors. These tools can save time and money, and help designers to create the best product possible.

Comparing the Different Rapid Prototype Making Tools on the Market Today

Rapid prototyping is a powerful tool for product designers and engineers, allowing them to quickly create physical models of their designs. With the right rapid prototyping tool, designers can quickly and accurately create prototypes that can be used for testing, marketing, and even production. With so many rapid prototyping tools on the market today, it can be difficult to know which one is right for you. In this article, we will compare the different rapid prototyping tools on the market today, so you can make an informed decision about which one is best for your needs.

The first type of rapid prototyping tool is 3D printing. 3D printing is a process that uses a computer-controlled printer to create three-dimensional objects from a digital file. 3D printing is a great option for creating prototypes quickly and accurately, and it is relatively inexpensive compared to other rapid prototyping tools. However, 3D printing is limited in terms of the materials it can use, and it is not suitable for creating complex shapes or intricate details.

The second type of rapid prototyping tool is CNC machining. CNC machining is a process that uses computer-controlled machines to cut and shape materials into precise shapes. CNC machining is a great option for creating complex shapes and intricate details, and it is also relatively inexpensive compared to other rapid prototyping tools. However, CNC machining is limited in terms of the materials it can use, and it is not suitable for creating prototypes quickly.

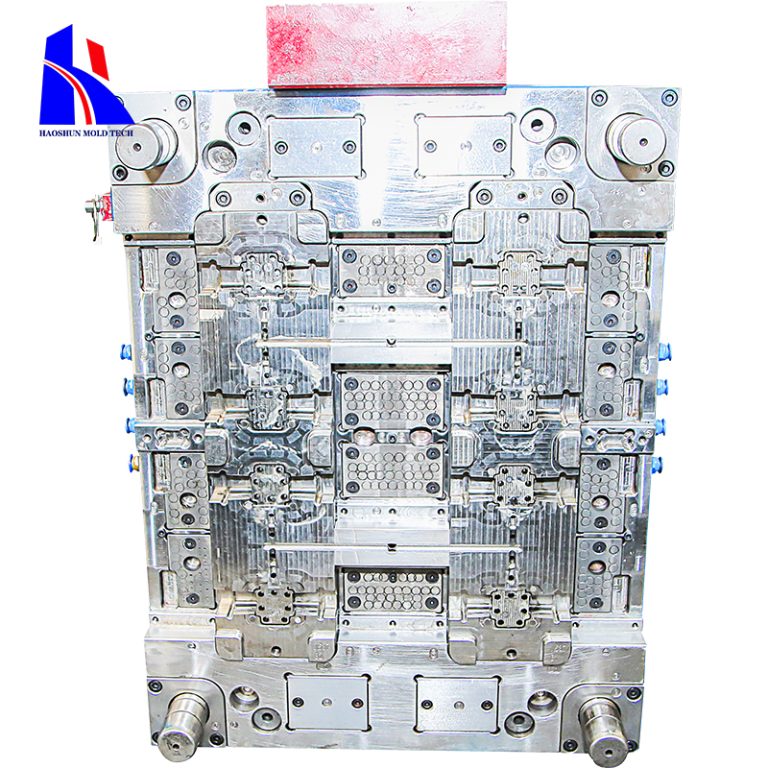

The third type of rapid prototyping tool is injection molding. Injection molding is a process that uses a computer-controlled machine to inject molten plastic into a mold to create a three-dimensional object. Injection molding is a great option for creating prototypes quickly and accurately, and it is also relatively inexpensive compared to other rapid prototyping tools. However, injection molding is limited in terms of the materials it can use, and it is not suitable for creating complex shapes or intricate details.

When choosing a rapid prototyping tool, it is important to consider your needs and budget. 3D printing, CNC machining, and injection molding are all great options for creating prototypes quickly and accurately, but each has its own advantages and disadvantages. By comparing the different rapid prototyping tools on the market today, you can make an informed decision about which one is best for your needs.