plastic parts

The Importance of Plastic Parts in Manufacturing Processes

Plastic parts play a crucial role in the manufacturing processes of various industries. From automotive to electronics, plastic components are widely used due to their versatility, durability, and cost-effectiveness. In this article, we will explore the importance of plastic parts in manufacturing processes and how they contribute to the overall efficiency and success of these industries.

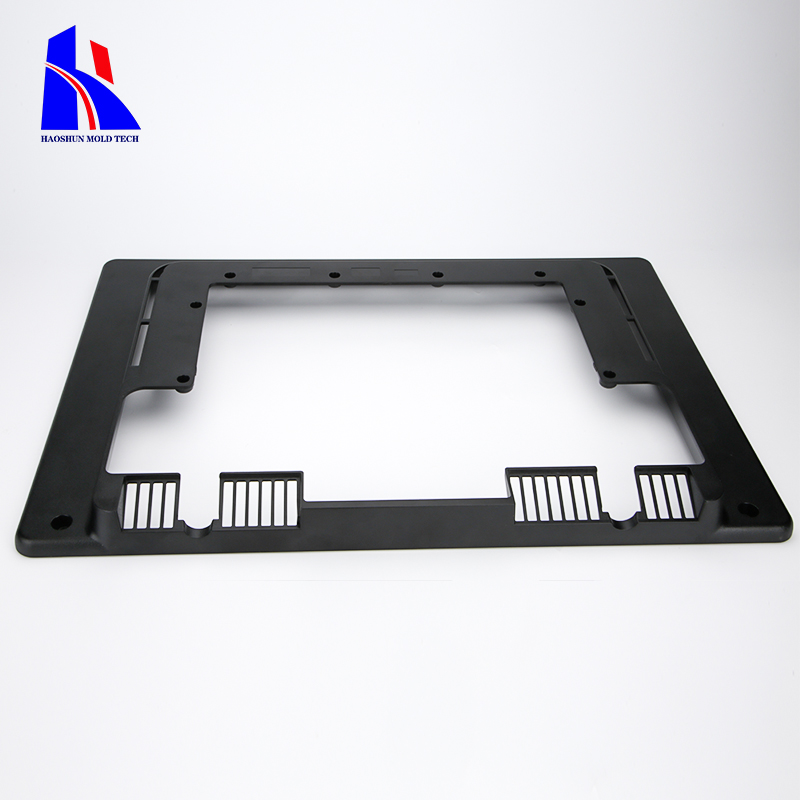

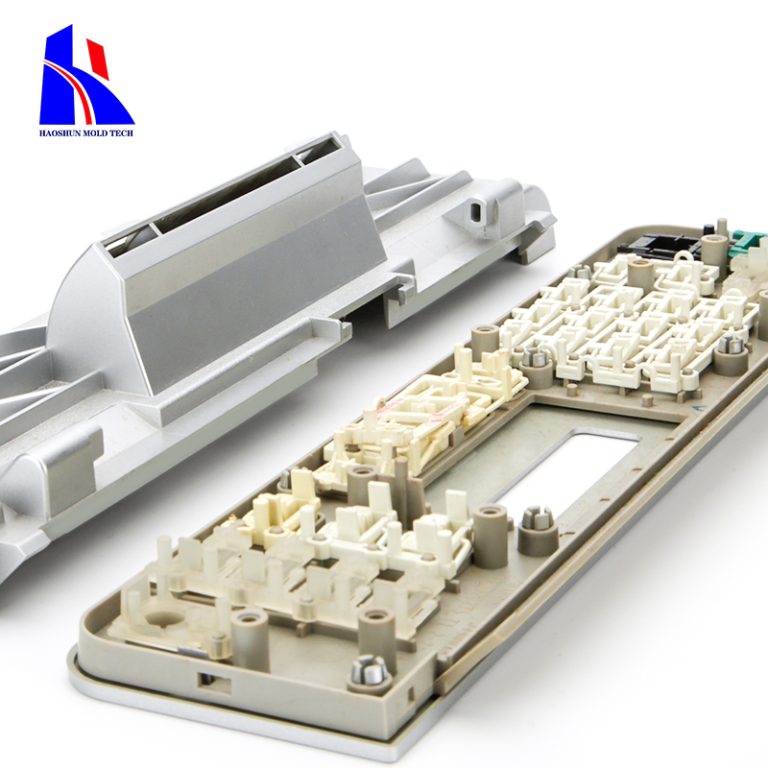

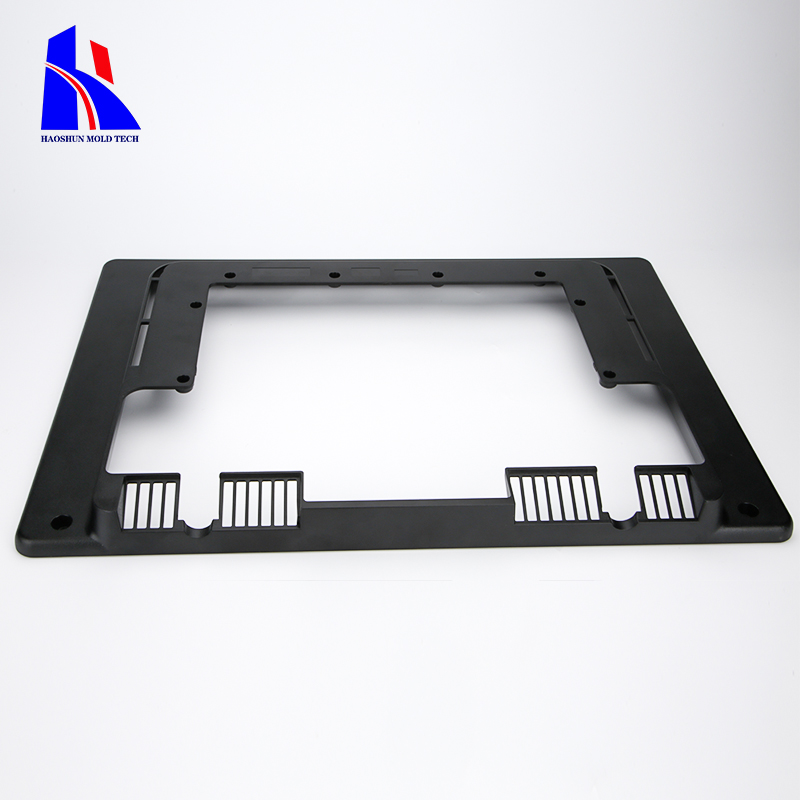

One of the primary reasons why plastic parts are highly valued in manufacturing is their versatility. Plastic can be molded into various shapes and sizes, allowing manufacturers to create intricate designs and complex geometries that would be difficult or impossible to achieve with other materials. This flexibility enables engineers and designers to push the boundaries of innovation and create products that meet specific requirements and customer demands.

Moreover, plastic parts are lightweight, making them ideal for industries that prioritize weight reduction, such as aerospace and automotive. By using plastic components instead of metal, manufacturers can significantly reduce the overall weight of their products, leading to improved fuel efficiency, increased payload capacity, and enhanced performance. This weight reduction also translates into cost savings, as lighter products require less energy to transport and operate.

In addition to their versatility and lightweight nature, plastic parts offer excellent durability and resistance to various environmental factors. Unlike metals, plastics are not susceptible to corrosion, rust, or degradation caused by moisture, chemicals, or extreme temperatures. This durability ensures that plastic components can withstand harsh conditions and maintain their functionality over an extended period, reducing the need for frequent replacements and repairs.

Furthermore, plastic parts are cost-effective compared to other materials commonly used in manufacturing processes. The production of plastic components involves lower material and labor costs, making them a more affordable option for manufacturers. Additionally, plastic parts can be mass-produced using injection molding techniques, allowing for high-volume production at a faster rate. This scalability and cost-efficiency make plastic parts an attractive choice for industries that require large quantities of components, such as consumer electronics and packaging.

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Our Services | OEM/ODM |

Another significant advantage of plastic parts is their ability to be easily customized and tailored to specific requirements. Manufacturers can choose from a wide range of plastic materials with different properties, such as strength, flexibility, and heat resistance, to meet the unique needs of their products. Additionally, plastic parts can be colored, textured, or coated to enhance their aesthetic appeal and improve the overall user experience. This customization capability allows manufacturers to differentiate their products in the market and cater to diverse customer preferences.

In conclusion, plastic parts play a vital role in the manufacturing processes of various industries due to their versatility, durability, cost-effectiveness, and customization capabilities. Their ability to be molded into complex shapes, lightweight nature, and resistance to environmental factors make them an ideal choice for industries that prioritize innovation, weight reduction, and durability. Additionally, the cost-efficiency and scalability of plastic parts make them a preferred option for high-volume production. As technology continues to advance, plastic parts will likely continue to evolve and contribute to the overall efficiency and success of manufacturing processes across industries.