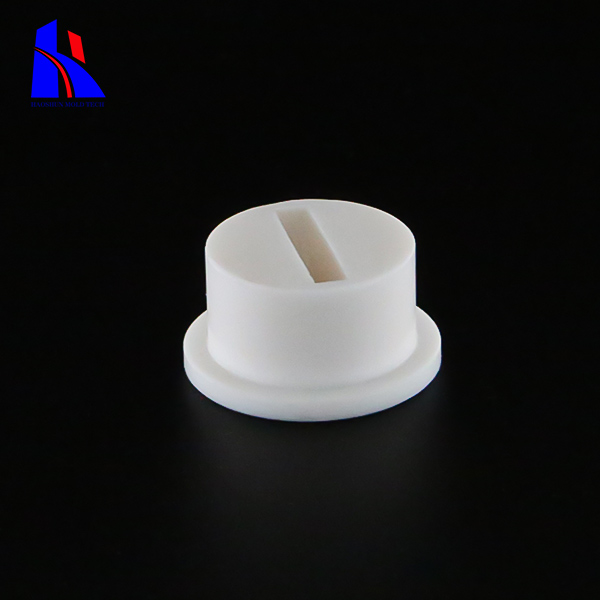

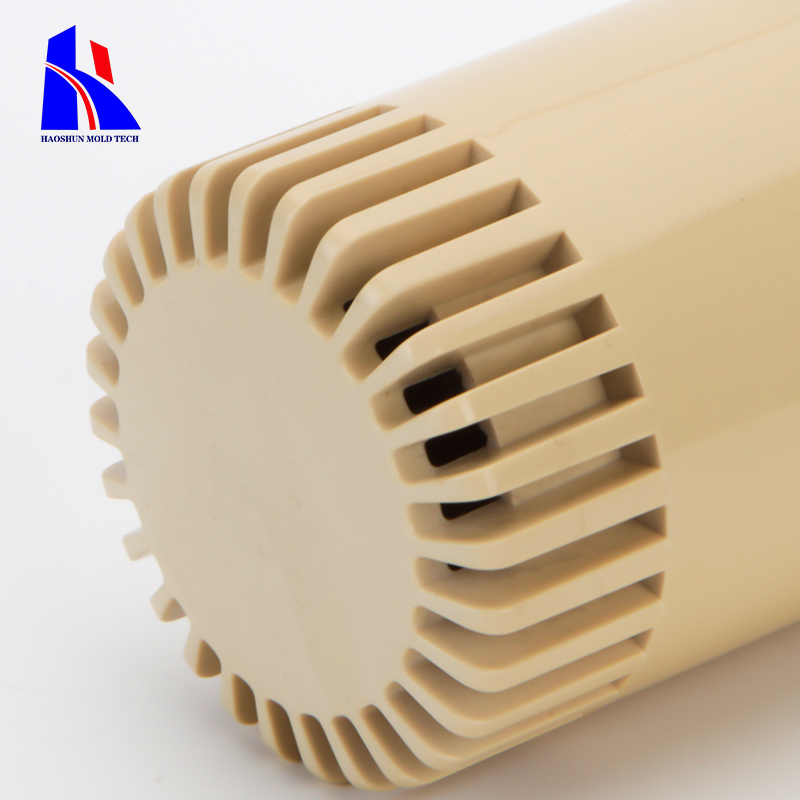

plastic production parts

The Benefits of Using Plastic Production Parts in Manufacturing

When it comes to manufacturing, plastic production parts offer a number of advantages over traditional metal parts. Plastic parts are lighter, more durable, and often more cost-effective than metal parts. Here are some of the key benefits of using plastic production parts in manufacturing:

1. Cost Savings: Plastic production parts are often much less expensive than metal parts. This is because plastic is easier to produce and requires less energy to manufacture. This cost savings can be passed on to the consumer, making plastic parts a great choice for budget-conscious manufacturers.

2. Durability: Plastic production parts are often more durable than metal parts. This is because plastic is more resistant to corrosion and wear and tear. This makes plastic parts ideal for use in harsh environments, such as those found in industrial settings.

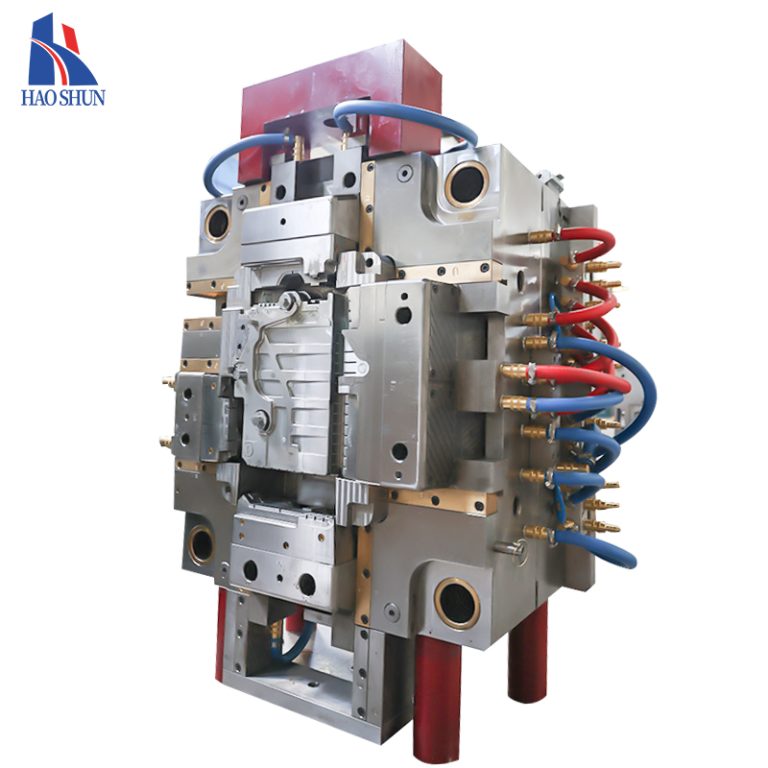

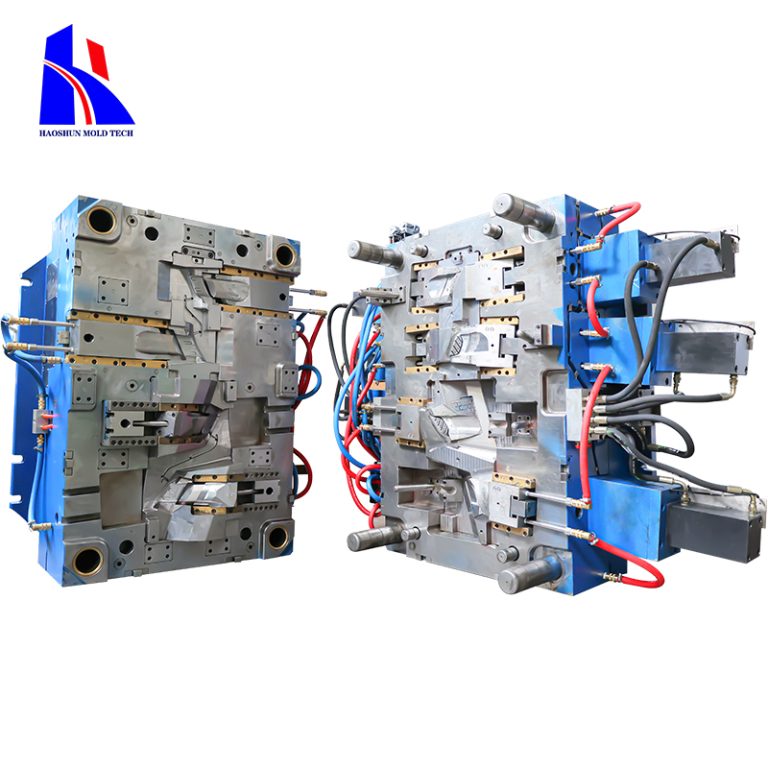

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Packing | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

3. Lightweight: Plastic production parts are much lighter than metal parts. This makes them easier to transport and install, which can save time and money.

4. Versatility: Plastic production parts can be easily customized to meet specific needs. This makes them ideal for use in a variety of applications, from medical devices to automotive components.

Overall, plastic production parts offer a number of advantages over traditional metal parts. They are lighter, more durable, and often more cost-effective. This makes them a great choice for manufacturers looking to save time and money.