small plastics desktop mini injection molding mach

Table of Contents

Benefits of Using Small Plastics Desktop Mini Injection Molding Machines

Small plastics desktop mini injection molding machines are becoming increasingly popular in the manufacturing industry due to their numerous benefits. These compact machines offer a cost-effective and efficient solution for producing small plastic parts in a variety of industries. In this article, we will explore the benefits of using small plastics desktop mini injection molding machines.

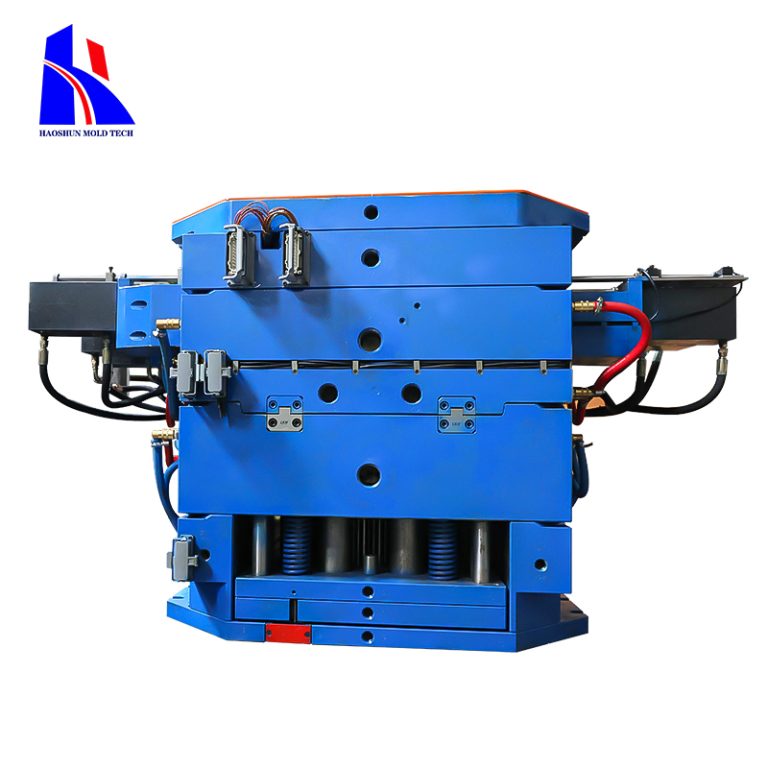

One of the main advantages of using small plastics desktop mini injection molding machines is their compact size. These machines are designed to fit on a desktop or workbench, making them ideal for small manufacturing spaces or workshops. This compact size also makes them easy to transport and set up, allowing for greater flexibility in production processes.

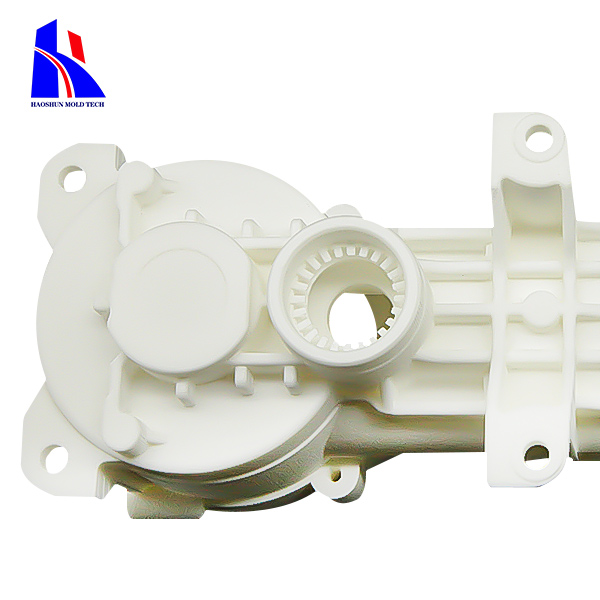

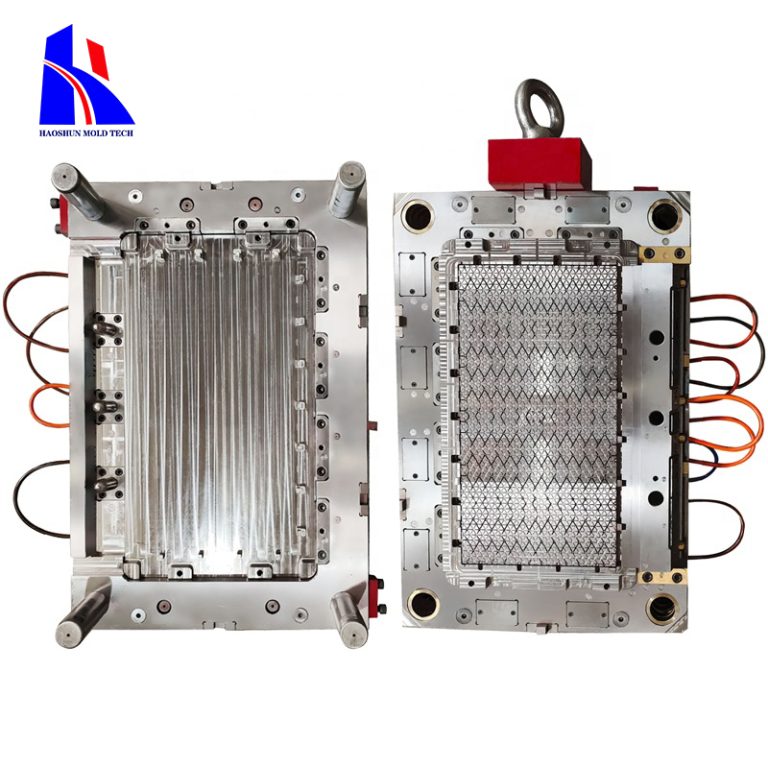

Despite their small size, small plastics desktop mini injection molding machines are capable of producing high-quality plastic parts with precision and accuracy. These machines are equipped with advanced technology and features that ensure consistent and reliable results. This level of precision is essential for industries that require tight tolerances and intricate designs in their plastic parts.

Another benefit of using small plastics desktop mini injection molding machines is their cost-effectiveness. These machines are more affordable than larger injection molding machines, making them a practical choice for small businesses or startups with limited budgets. Additionally, the low operating costs of these machines make them a cost-effective solution for long-term production needs.

Small plastics desktop mini injection molding machines also offer a quick turnaround time for production. These machines have fast cycle times, allowing for rapid production of plastic parts. This speed and efficiency can help businesses meet tight deadlines and increase overall productivity.

In addition to their compact size and cost-effectiveness, small plastics desktop mini injection molding machines are also user-friendly. These machines are easy to operate and require minimal training for operators. This ease of use allows businesses to quickly integrate these machines into their production processes without significant downtime or disruptions.

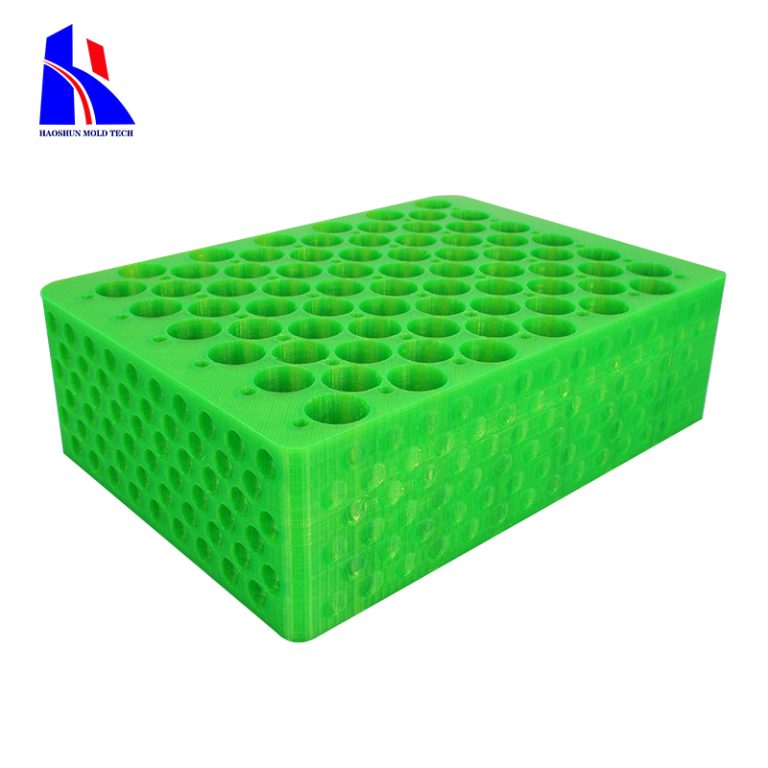

Furthermore, small plastics desktop mini injection molding machines are versatile and can be used for a wide range of applications. Whether producing small plastic components for electronics, automotive, medical devices, or consumer products, these machines can handle a variety of materials and designs. This versatility makes them a valuable asset for businesses looking to diversify their product offerings.

Overall, small plastics desktop mini injection molding machines offer a range of benefits for businesses in need of cost-effective, efficient, and precise plastic part production. Their compact size, affordability, speed, user-friendliness, and versatility make them an attractive option for a wide range of industries. By investing in a small plastics desktop mini injection molding machine, businesses can streamline their production processes, increase productivity, and stay competitive in today’s fast-paced manufacturing environment.

Tips for Choosing the Right Small Plastics Desktop Mini Injection Molding Machine

Small plastics desktop mini injection molding machines are becoming increasingly popular among small businesses and hobbyists looking to create their own plastic products. These machines offer a cost-effective and efficient way to produce small plastic parts in-house, without the need for expensive industrial equipment. However, with so many options available on the market, it can be overwhelming to choose the right machine for your needs. In this article, we will provide some tips to help you select the best small plastics desktop mini injection molding machine for your specific requirements.

First and foremost, it is essential to consider the size and capacity of the machine. Small plastics desktop mini injection molding machines come in a variety of sizes, with different injection capacities. It is crucial to choose a machine that can accommodate the size and volume of the parts you intend to produce. Consider the dimensions of the parts you will be molding and ensure that the machine you choose can handle them effectively.

Another important factor to consider is the type of material you will be using. Small plastics desktop mini injection molding machines are designed to work with a variety of materials, including ABS, PP, PE, and more. Make sure that the machine you choose is compatible with the type of material you plan to use for your projects. Some machines may have limitations on the types of materials they can process, so it is essential to check this before making a purchase.

| Product Name | OEM Plastic injection molding Parts |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

Additionally, it is crucial to consider the precision and accuracy of the machine. Small plastics desktop mini injection molding machines vary in terms of their precision and accuracy, with some machines offering higher levels of control and consistency than others. If you require tight tolerances and high-quality finishes for your parts, it is essential to choose a machine that can deliver the level of precision you need.

When selecting a small plastics desktop mini injection molding machine, it is also important to consider the ease of use and maintenance. Look for a machine that is user-friendly and easy to operate, with intuitive controls and clear instructions. Additionally, consider the maintenance requirements of the machine and ensure that you can easily access replacement parts and service support when needed.

Finally, it is essential to consider the cost of the machine. Small plastics desktop mini injection molding machines vary in price, depending on their size, capacity, features, and brand. Set a budget for your machine and compare different options to find the best value for your money. Keep in mind that investing in a high-quality machine may cost more upfront but can save you money in the long run by reducing downtime and maintenance costs.

In conclusion, choosing the right small plastics desktop mini injection molding machine requires careful consideration of factors such as size, capacity, material compatibility, precision, ease of use, maintenance, and cost. By following these tips, you can select a machine that meets your specific requirements and helps you achieve your plastic molding goals effectively and efficiently.