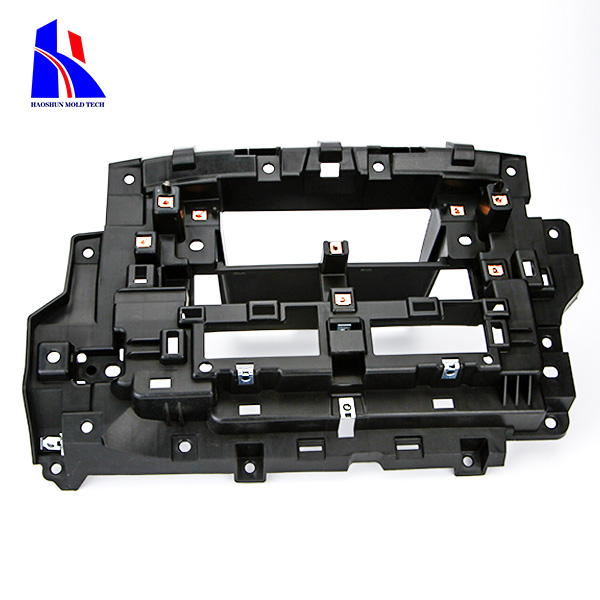

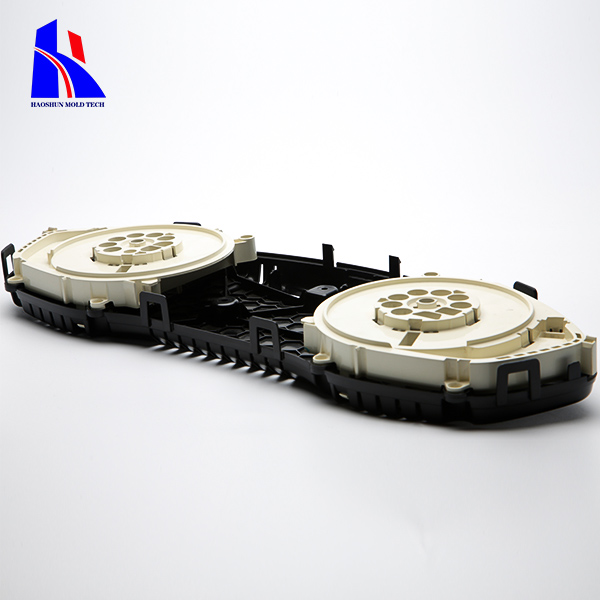

abs plastic part injection molding rubber and plastic parts

Injection molding is a widely used manufacturing process for producing parts from both plastic and rubber materials. Here’s a detailed overview of ABS plastic part injection molding and the general principles related to rubber and plastic parts. 1.Acrylonitrile Butadiene Styrene (ABS) is a common thermoplastic known for its strength, toughness, and impact resistance.2.Properties:3.Good mechanical properties4.High…