automatic feeding of plastic in injections molding

Advantages of Automatic Feeding Systems in Injection Molding for Plastic Manufacturing

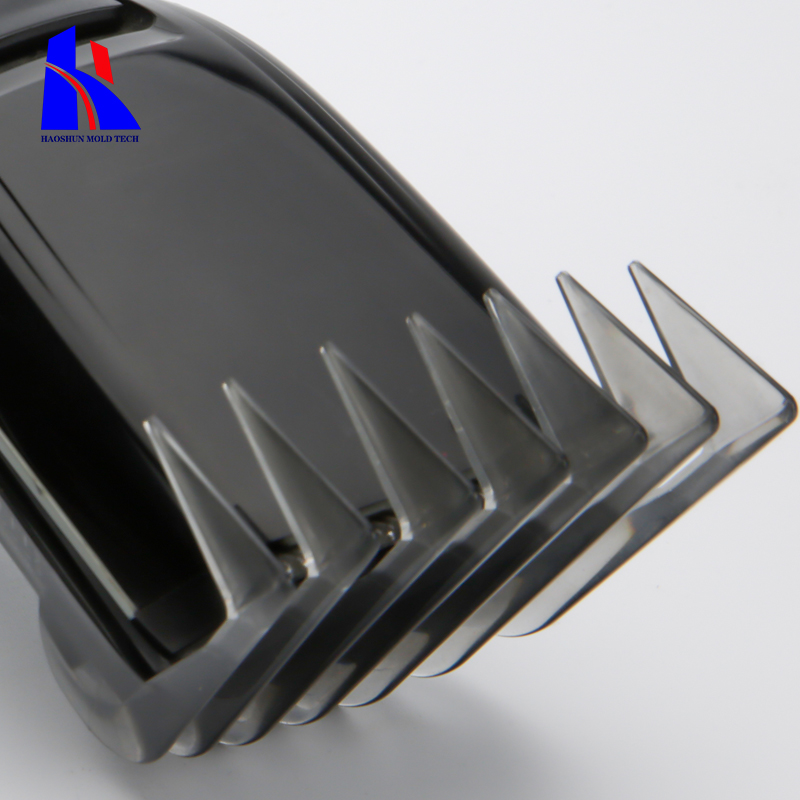

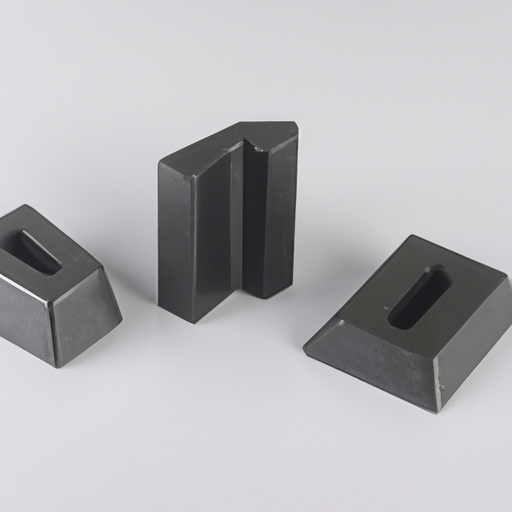

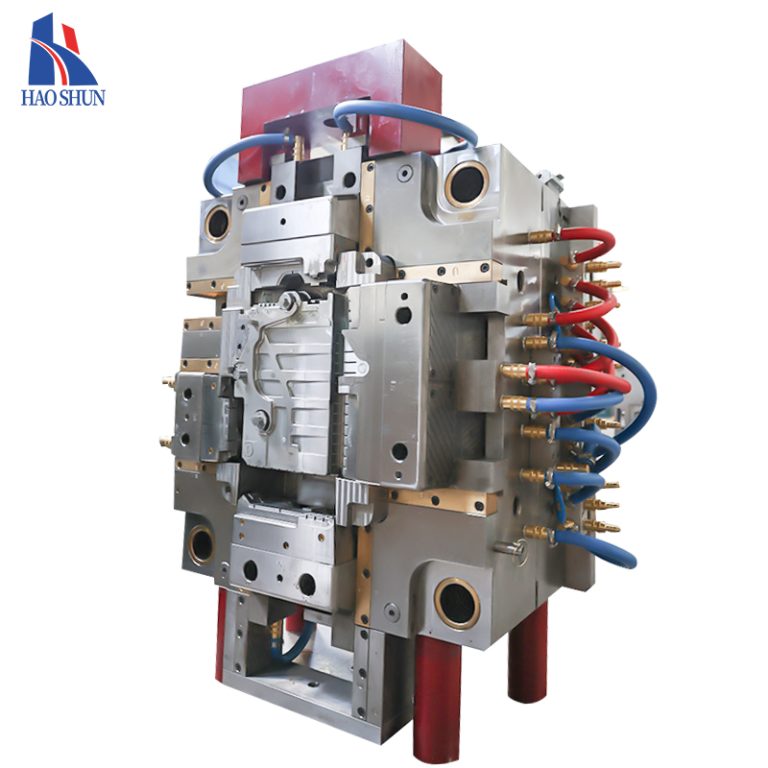

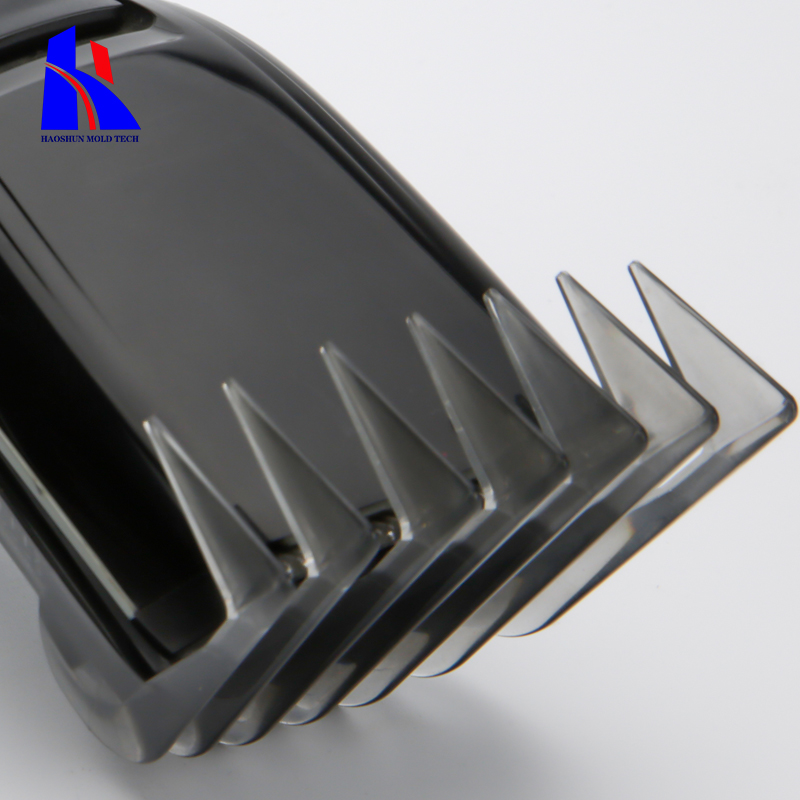

Injection molding is a widely used manufacturing process in the production of plastic parts. It involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. One key aspect of injection molding is the feeding of plastic material into the machine. Traditionally, this process has been done manually, with operators loading plastic pellets into hoppers or feeders. However, in recent years, automatic feeding systems have become increasingly popular in the industry.

Automatic feeding systems offer a number of advantages over manual feeding. One of the main benefits is increased efficiency. With automatic feeding, the process is streamlined and automated, reducing the need for manual labor and increasing the overall productivity of the injection molding operation. This can result in faster cycle times and higher output, ultimately leading to cost savings for the manufacturer.

Another advantage of automatic feeding systems is improved consistency and accuracy. Manual feeding can be prone to human error, such as overfilling or underfilling the hopper, which can lead to variations in the quality of the finished parts. Automatic feeding systems, on the other hand, are designed to deliver precise amounts of plastic material to the machine, ensuring a consistent and uniform feed every time. This can help to improve the overall quality of the parts being produced and reduce the amount of scrap or rework needed.

In addition to efficiency and consistency, automatic feeding systems also offer benefits in terms of safety and ergonomics. Manual feeding can be a physically demanding task, requiring operators to lift and carry heavy bags of plastic pellets and load them into the machine. This can lead to strain and injury over time. Automatic feeding systems eliminate the need for manual handling of materials, reducing the risk of injury and creating a safer working environment for operators.

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

Furthermore, automatic feeding systems can also help to reduce material waste. By delivering precise amounts of plastic material to the machine, these systems can minimize the amount of excess material that is used in the production process. This not only helps to reduce costs but also has environmental benefits by reducing the amount of plastic waste generated.

Overall, automatic feeding systems offer a range of advantages for manufacturers in the injection molding industry. From increased efficiency and consistency to improved safety and reduced waste, these systems can help to streamline the production process and improve the overall quality of the finished parts. As technology continues to advance, automatic feeding systems are likely to become even more prevalent in the industry, offering manufacturers a competitive edge in the fast-paced world of plastic manufacturing.