plastic injection

The Benefits of Using Plastic Injection Molding for Manufacturing

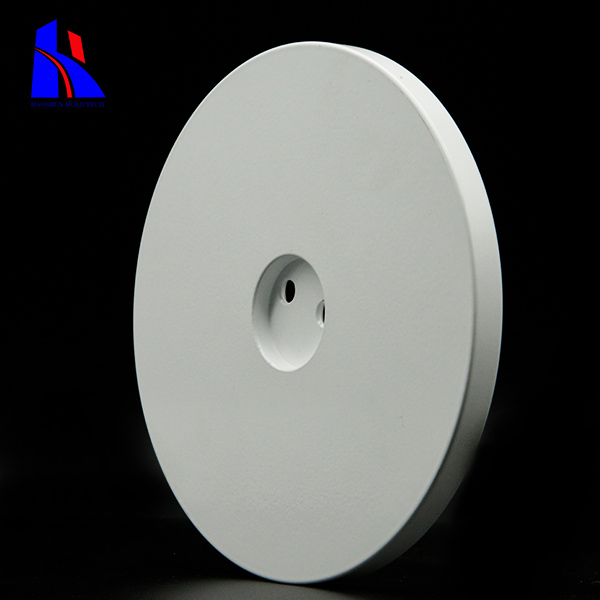

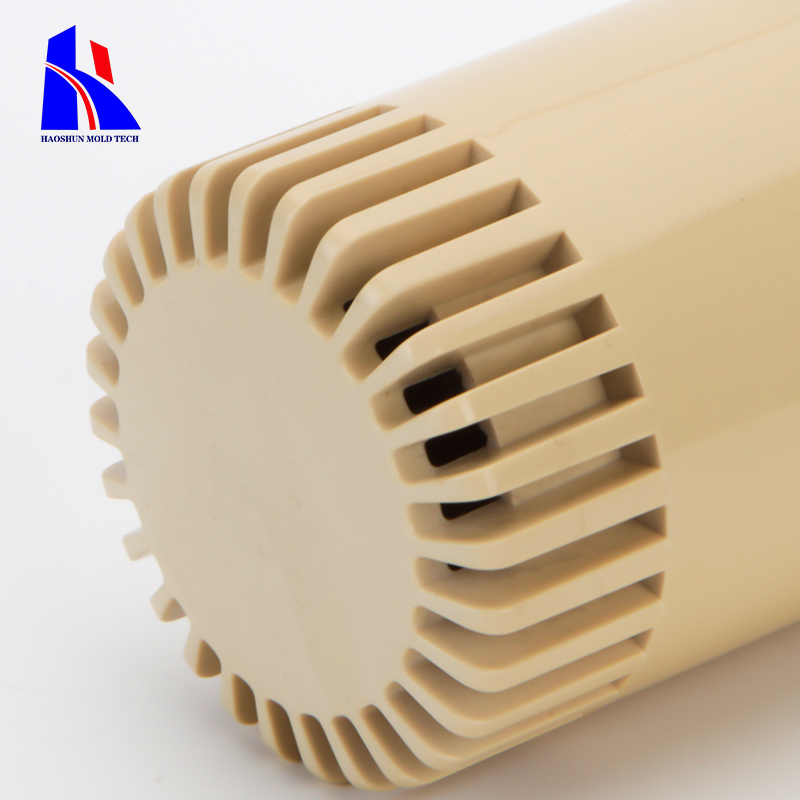

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process is highly versatile and can be used to produce a wide range of products, from small components to large parts. There are many benefits to using plastic injection molding for manufacturing, making it a popular choice for many industries.

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Our Services | OEM/ODM |

One of the key benefits of plastic injection molding is its cost-effectiveness. The initial tooling costs for plastic injection molding can be high, but once the mold is created, the cost per part is relatively low. This makes plastic injection molding a cost-effective option for high-volume production runs. Additionally, the high level of automation in the plastic injection molding process helps to reduce labor costs, further increasing its cost-effectiveness.

Another benefit of plastic injection molding is its ability to produce complex and intricate parts with high precision. The mold cavity can be designed to create parts with intricate details and tight tolerances, ensuring that each part is consistent and accurate. This level of precision is difficult to achieve with other manufacturing processes, making plastic injection molding a preferred choice for parts that require high levels of accuracy.

Plastic injection molding also offers a wide range of material options, allowing manufacturers to choose the best material for their specific application. From commodity plastics like polyethylene and polypropylene to engineering plastics like ABS and nylon, there is a material to suit every need. Additionally, additives can be incorporated into the plastic material during the molding process to enhance its properties, such as adding UV stabilizers for outdoor applications or flame retardants for safety-critical parts.

The versatility of plastic injection molding extends to the types of products that can be produced. From small, intricate components to large, complex parts, plastic injection molding can accommodate a wide range of part sizes and shapes. This flexibility makes it a suitable option for a variety of industries, from automotive and aerospace to consumer goods and medical devices.

In addition to its cost-effectiveness, precision, material options, and versatility, plastic injection molding also offers fast production times. Once the mold is created, the injection molding process itself is quick and efficient, allowing for high-volume production runs to be completed in a short amount of time. This rapid production capability is essential for meeting tight deadlines and keeping up with consumer demand.

Overall, plastic injection molding is a highly efficient and effective manufacturing process that offers a wide range of benefits. From cost-effectiveness and precision to material options and versatility, plastic injection molding is a preferred choice for many industries. Its ability to produce complex parts with high accuracy and fast production times makes it a valuable tool for manufacturers looking to streamline their production processes and deliver high-quality products to their customers.