plastic parts for automotive industry

The Importance of Plastic Parts in the Automotive Industry

The automotive industry is constantly evolving, with new technologies and materials being introduced to improve the performance, safety, and efficiency of vehicles. One material that has become increasingly important in the automotive industry is plastic. Plastic parts are now widely used in the manufacturing of vehicles, and their importance cannot be overstated.

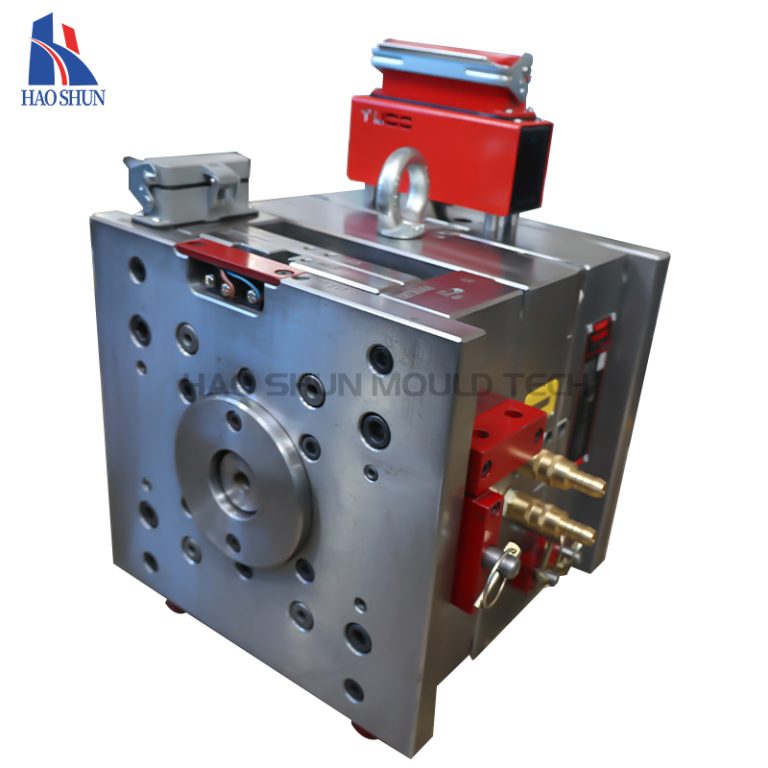

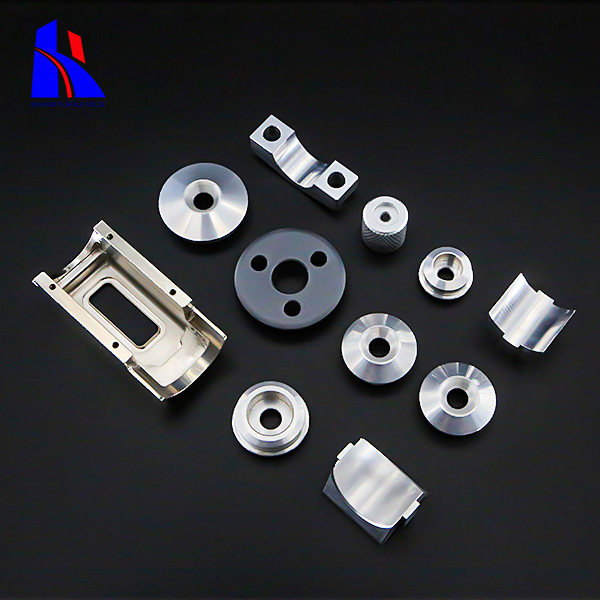

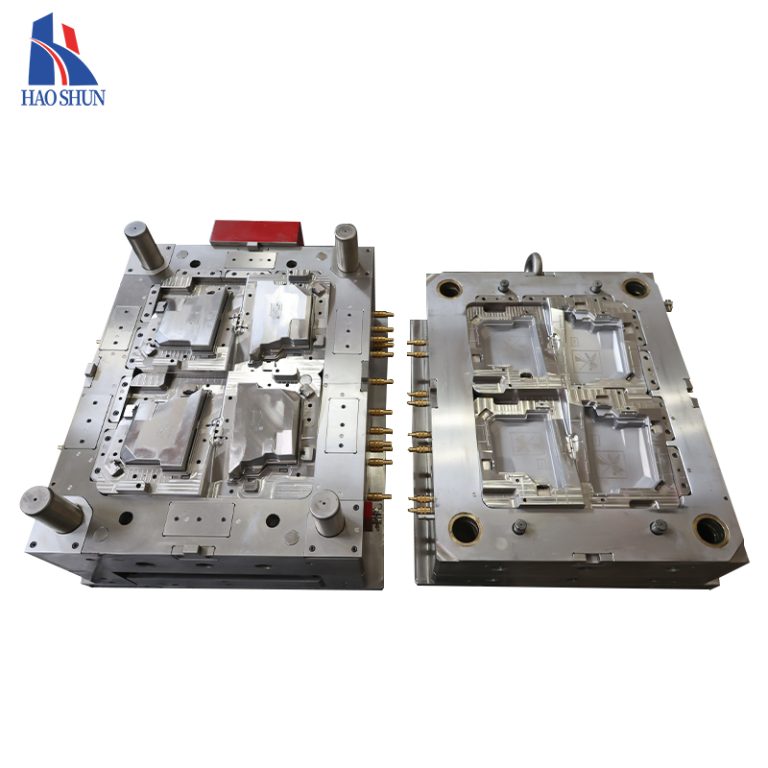

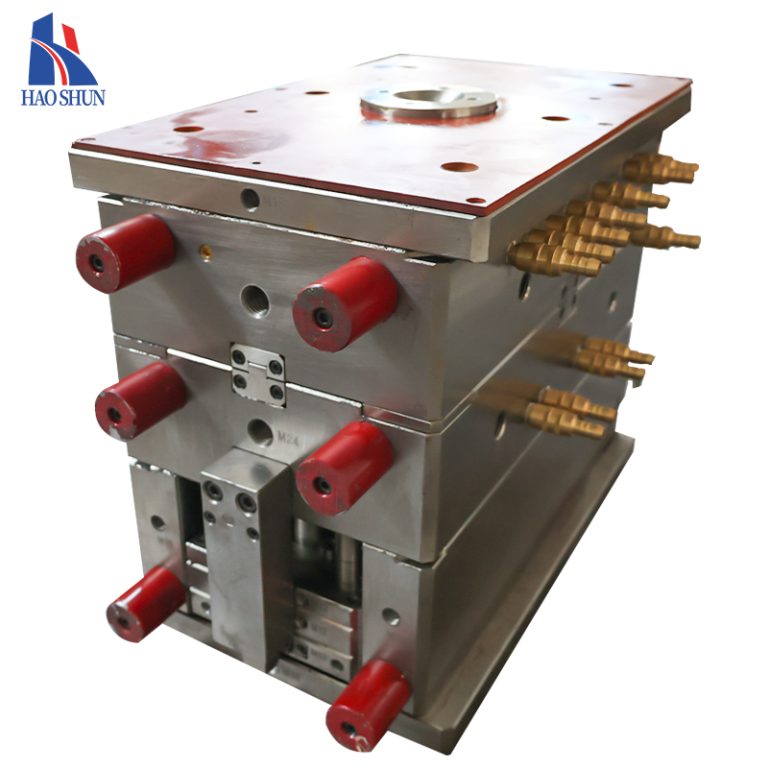

One of the main reasons why plastic parts are so important in the automotive industry is their versatility. Plastic can be molded into any shape or size, allowing for the creation of complex and intricate designs. This flexibility is crucial in the automotive industry, where vehicles need to be aerodynamic and visually appealing. Plastic parts can be molded to fit seamlessly into the overall design of a vehicle, enhancing its aesthetic appeal.

In addition to their versatility, plastic parts also offer several practical advantages. One of the most significant advantages is their lightweight nature. Compared to traditional materials such as metal, plastic is much lighter, which can have a significant impact on a vehicle’s fuel efficiency. Lighter vehicles require less energy to move, resulting in improved fuel economy and reduced emissions. This is particularly important in today’s world, where there is a growing emphasis on sustainability and reducing our carbon footprint.

Another advantage of plastic parts in the automotive industry is their durability. Plastic is a highly durable material that can withstand extreme temperatures, harsh weather conditions, and everyday wear and tear. This durability ensures that plastic parts can withstand the rigors of daily use and last for a long time without needing to be replaced. This not only reduces maintenance costs but also improves the overall reliability and longevity of vehicles.

Plastic parts also play a crucial role in enhancing the safety of vehicles. Many safety features in modern vehicles, such as airbags, seat belts, and bumpers, are made from plastic. Plastic’s ability to absorb impact and distribute forces evenly makes it an ideal material for these safety components. In the event of a collision, plastic parts can help protect the occupants of a vehicle by absorbing and dissipating the energy generated during the impact.

| Product Name | OEM Plastic injection molding Parts |

| Quotation | According to your drawing (material / Size / Required Technology / Etc.) |

Furthermore, plastic parts offer cost advantages in the automotive industry. Plastic is a relatively inexpensive material compared to other alternatives such as metal. This cost advantage allows automakers to produce vehicles at a lower cost, making them more affordable for consumers. Additionally, plastic parts are easier and cheaper to manufacture compared to metal parts, as they require less energy and fewer resources. This cost-effectiveness is a significant factor in the widespread adoption of plastic parts in the automotive industry.

In conclusion, plastic parts have become indispensable in the automotive industry due to their versatility, practical advantages, safety features, and cost-effectiveness. Their ability to be molded into any shape or size, lightweight nature, durability, and affordability make them an ideal choice for automakers. As the automotive industry continues to evolve, plastic parts will undoubtedly play an even more significant role in shaping the vehicles of the future.