raw materials for plastic injection molding produc

Table of Contents

Benefits of Using Recycled Plastic in Injection Molding Products

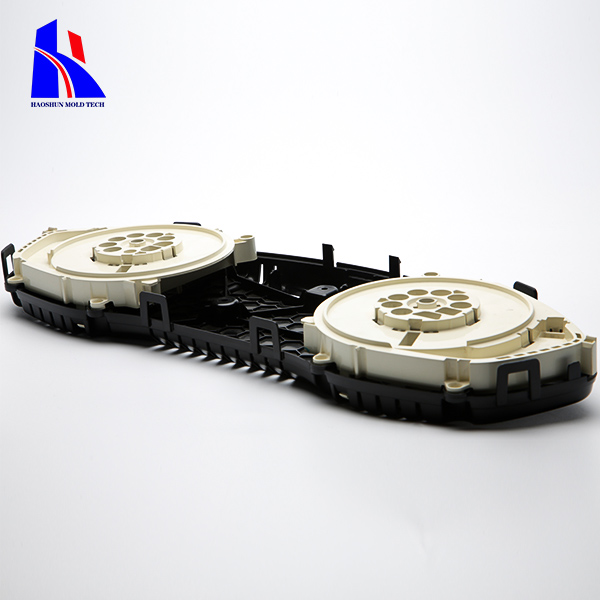

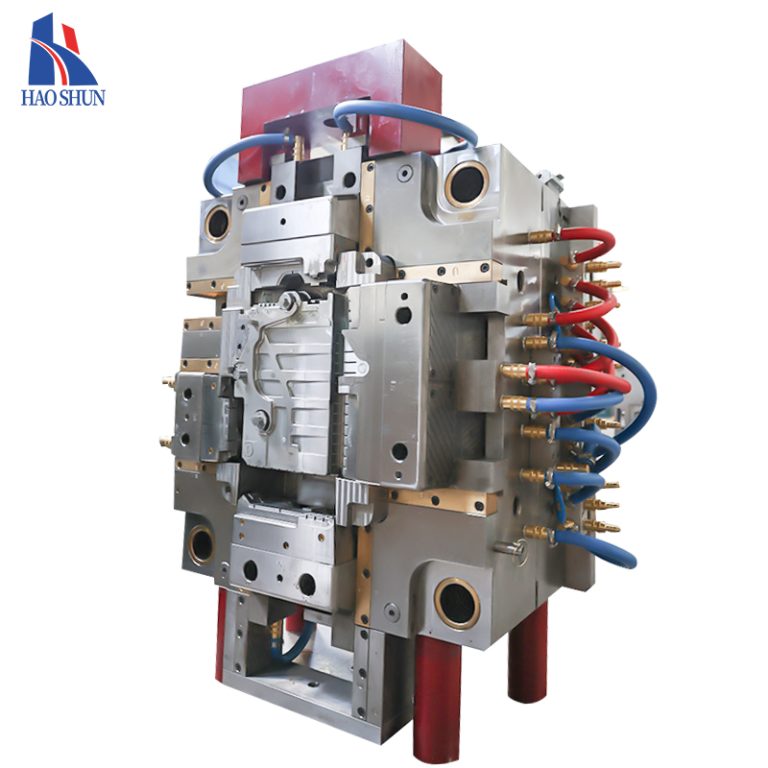

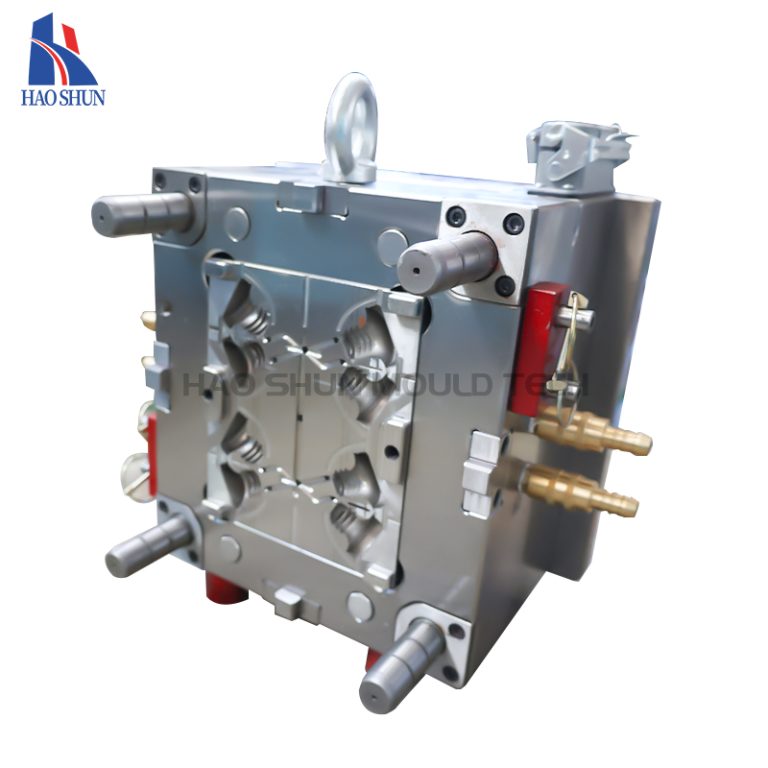

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold cavity to create a wide range of products. From automotive parts to household items, plastic injection molding is a versatile and cost-effective method for producing high-quality plastic products. One of the key components in the plastic injection molding process is the raw material used to create the final product.

Traditionally, plastic injection molding has relied on virgin plastic resins as the primary raw material. However, with growing concerns about environmental sustainability and the impact of plastic waste on the planet, there has been a shift towards using recycled plastic in injection molding products. Using recycled plastic in injection molding offers a number of benefits, both for manufacturers and for the environment.

One of the primary benefits of using recycled plastic in injection molding products is the reduction of waste and the conservation of natural resources. By using recycled plastic, manufacturers can divert plastic waste from landfills and reduce the need for new plastic production. This not only helps to reduce the environmental impact of plastic production but also conserves valuable resources such as oil, which is used to create virgin plastic resins.

In addition to environmental benefits, using recycled plastic in injection molding products can also offer cost savings for manufacturers. Recycled plastic resins are often less expensive than virgin resins, making them a cost-effective alternative for producing plastic products. This cost savings can help manufacturers reduce production costs and improve their bottom line, making recycled plastic a viable option for injection molding products.

Another benefit of using recycled plastic in injection molding products is the ability to meet consumer demand for sustainable and eco-friendly products. With increasing awareness of environmental issues, consumers are becoming more conscious of the products they purchase and are seeking out sustainable alternatives. By using recycled plastic in injection molding products, manufacturers can appeal to environmentally conscious consumers and differentiate their products in the market.

Furthermore, using recycled plastic in injection molding products can also help to improve the overall sustainability of the manufacturing process. By incorporating recycled materials into their products, manufacturers can reduce their carbon footprint and minimize their impact on the environment. This commitment to sustainability can enhance the reputation of the company and attract environmentally conscious customers who value sustainable practices.

Overall, the benefits of using recycled plastic in injection molding products are clear. From reducing waste and conserving resources to offering cost savings and meeting consumer demand for sustainable products, recycled plastic offers a range of advantages for manufacturers. By incorporating recycled plastic into their injection molding products, manufacturers can not only improve their bottom line but also contribute to a more sustainable and environmentally friendly future.

The Impact of Biodegradable Raw Materials on Plastic Injection Molding Industry

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold cavity to create a wide range of products. However, the environmental impact of traditional plastic materials has raised concerns about sustainability and pollution. In response to these concerns, the plastic injection molding industry has been exploring the use of biodegradable raw materials as an alternative to traditional plastics.

Biodegradable raw materials are derived from renewable resources such as corn, sugarcane, and other plant-based sources. These materials are designed to break down naturally in the environment, reducing the amount of plastic waste that ends up in landfills and oceans. In addition to their environmental benefits, biodegradable raw materials also offer advantages in terms of production efficiency and product quality.

One of the key advantages of using biodegradable raw materials in plastic injection molding is their lower carbon footprint. Traditional plastics are typically made from fossil fuels, which contribute to greenhouse gas emissions and climate change. In contrast, biodegradable raw materials are derived from plants that absorb carbon dioxide from the atmosphere, making them a more sustainable option for manufacturers.

In addition to their environmental benefits, biodegradable raw materials also offer advantages in terms of production efficiency. These materials can be processed at lower temperatures, reducing energy consumption and production costs. They also have a shorter cooling time, which can lead to faster cycle times and increased productivity. Furthermore, biodegradable raw materials are less likely to warp or shrink during the molding process, resulting in higher quality finished products.

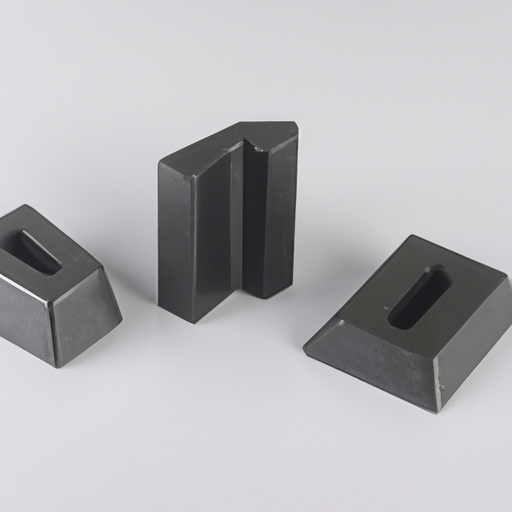

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

The use of biodegradable raw materials in plastic injection molding can also help manufacturers meet consumer demand for eco-friendly products. As awareness of environmental issues grows, consumers are increasingly seeking out products that are made from sustainable materials. By using biodegradable raw materials, manufacturers can appeal to environmentally conscious consumers and differentiate their products in the marketplace.

Despite the many benefits of biodegradable raw materials, there are some challenges associated with their use in plastic injection molding. One of the main challenges is the cost of these materials, which can be higher than traditional plastics. However, as demand for sustainable products continues to grow, the cost of biodegradable raw materials is expected to decrease as production scales up.

Another challenge is the limited availability of biodegradable raw materials. While there are a variety of plant-based sources that can be used to produce biodegradable plastics, not all of these sources are readily accessible or cost-effective. As a result, manufacturers may need to invest in research and development to identify new sources of biodegradable raw materials and optimize their production processes.

In conclusion, the use of biodegradable raw materials in plastic injection molding has the potential to revolutionize the industry and reduce its environmental impact. These materials offer a sustainable alternative to traditional plastics, with advantages in terms of production efficiency, product quality, and consumer appeal. While there are challenges associated with their use, the long-term benefits of biodegradable raw materials make them a promising option for manufacturers looking to create more sustainable products.