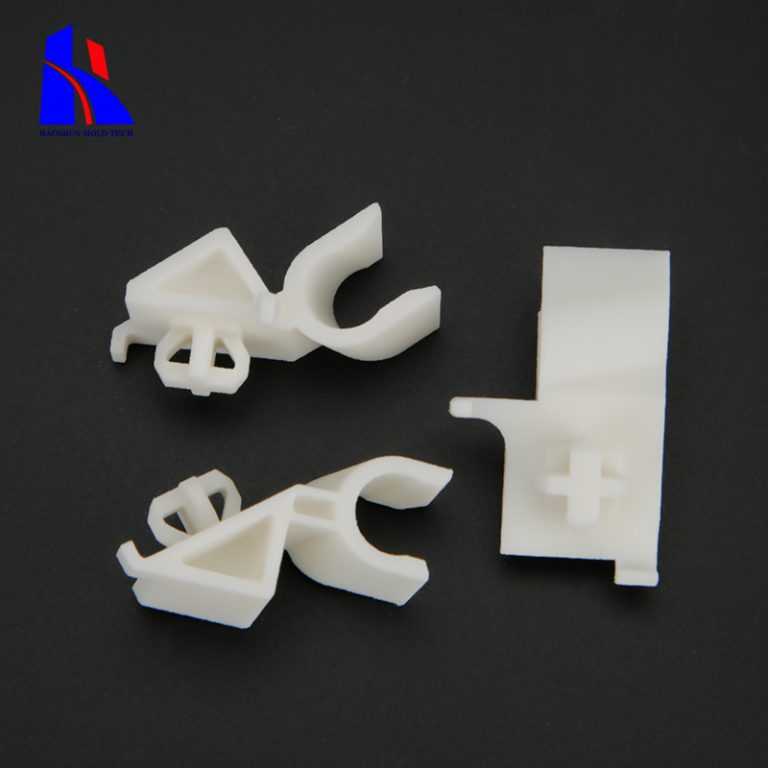

trophy parts plastic

The Benefits of Using Plastic for Trophy Parts: Exploring the Advantages of Plastic for Trophy Manufacturing

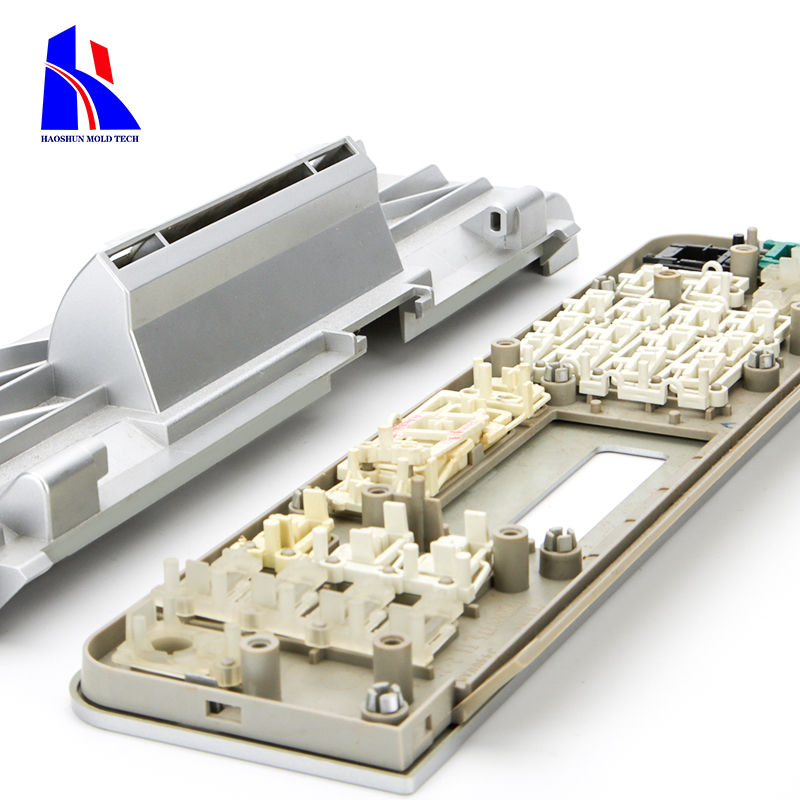

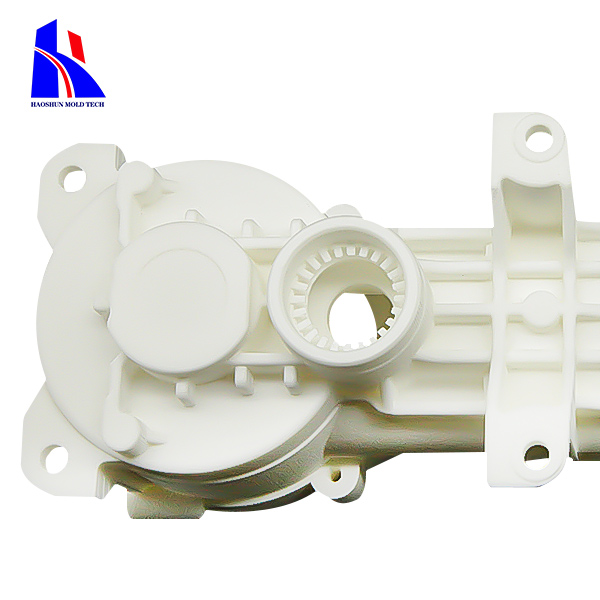

The use of plastic for trophy parts has become increasingly popular in recent years due to its many advantages. Plastic is a lightweight, durable, and cost-effective material that can be used to create a wide variety of trophy parts. It is also easy to customize and can be used to create intricate designs.

One of the primary benefits of using plastic for trophy parts is its durability. Plastic is a strong and resilient material that can withstand wear and tear, making it ideal for trophy parts that will be used for a long time. Additionally, plastic is resistant to corrosion and other environmental factors, making it a great choice for outdoor trophies.

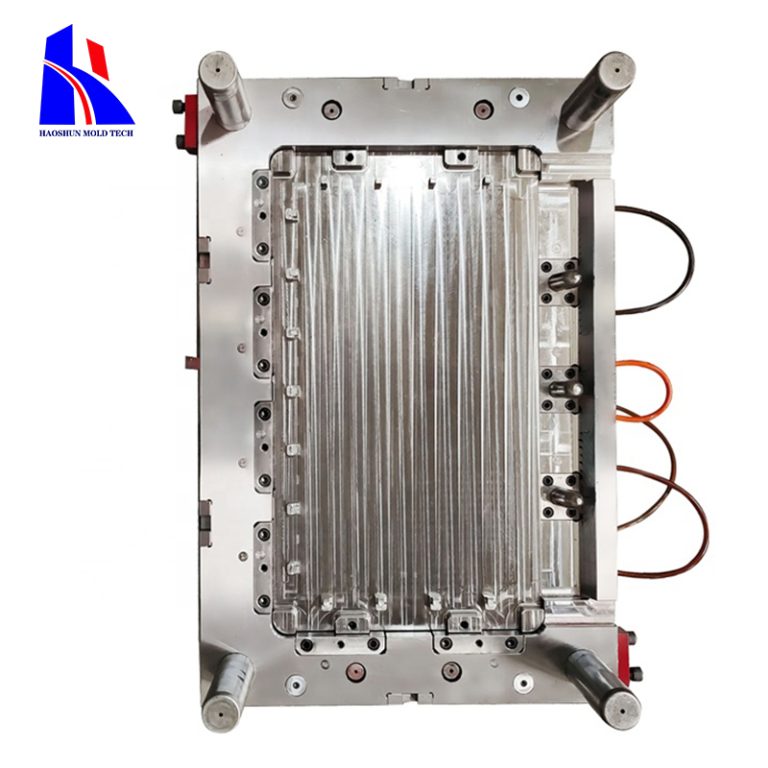

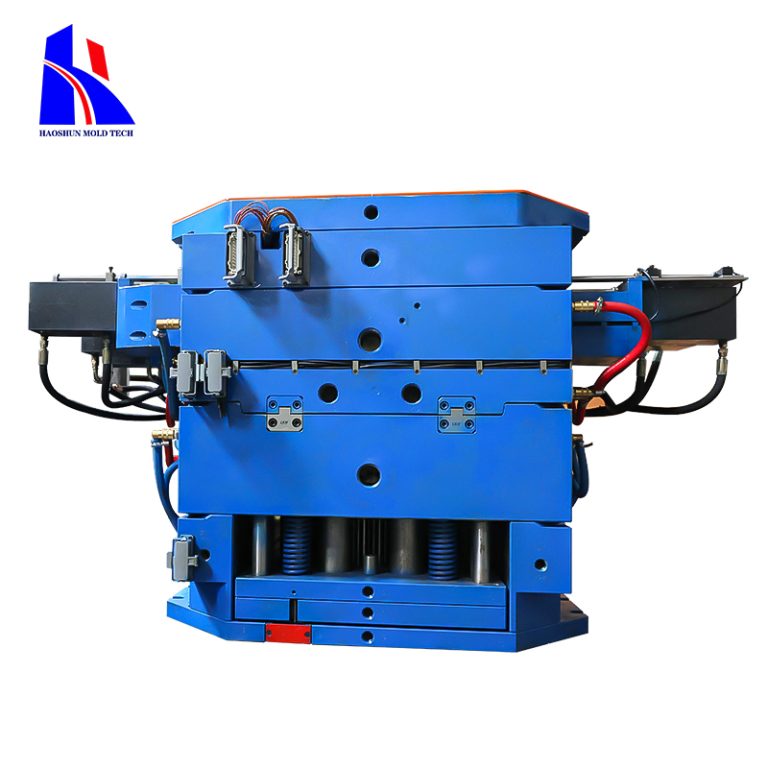

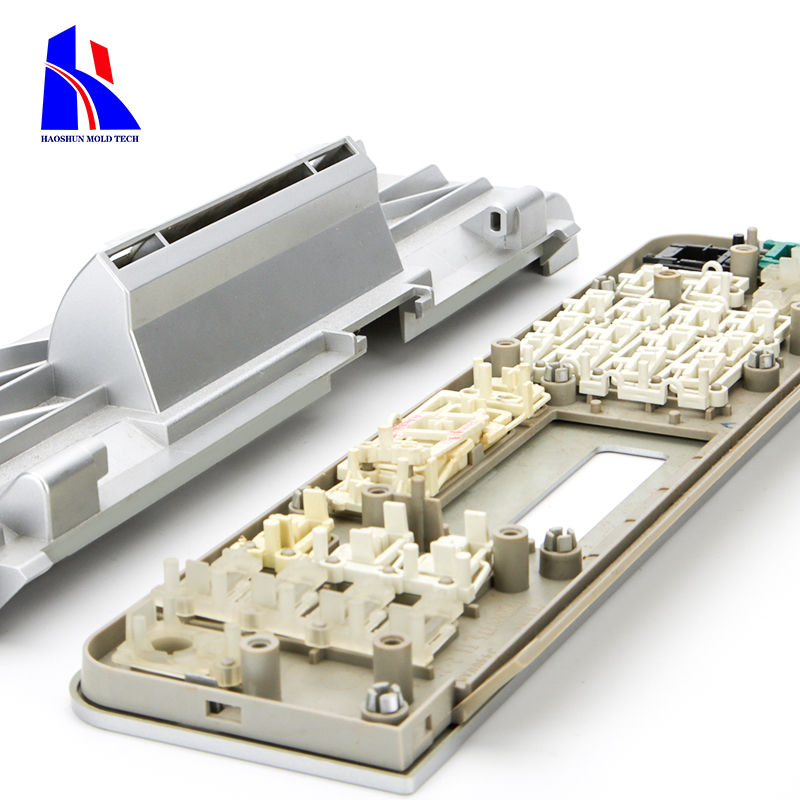

| Product Name | OEM Plastic injection molding Parts |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

Another advantage of using plastic for trophy parts is its cost-effectiveness. Plastic is a relatively inexpensive material, making it a great choice for those looking to save money on trophy parts. Additionally, plastic is easy to customize, allowing for intricate designs and shapes to be created without the need for expensive tools or machinery.

Finally, plastic is a lightweight material, making it easy to transport and store. This makes it ideal for trophies that will be moved around or stored away for long periods of time. Additionally, plastic is easy to clean and maintain, making it a great choice for trophies that will be used frequently.

Overall, plastic is an excellent choice for trophy parts due to its durability, cost-effectiveness, and lightweight nature. It is easy to customize and can be used to create intricate designs without the need for expensive tools or machinery. Additionally, plastic is resistant to corrosion and other environmental factors, making it a great choice for outdoor trophies. For these reasons, plastic is an ideal material for trophy parts.