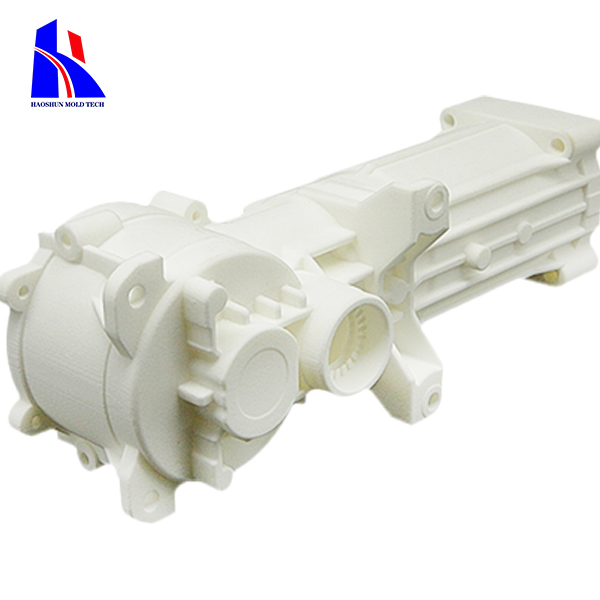

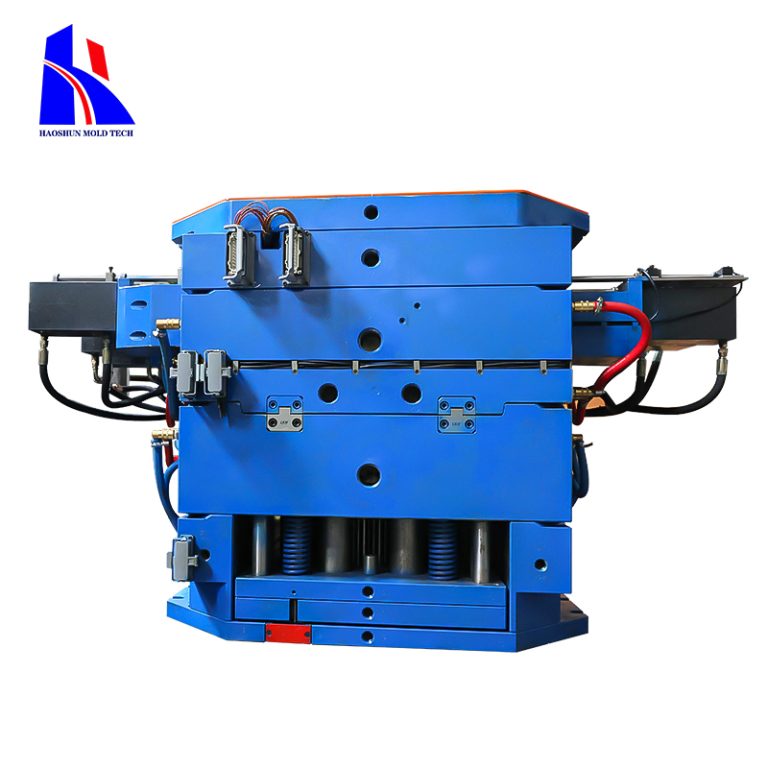

low pressure mold

Table of Contents

Exploring the Benefits of Low Pressure Molding for Plastic Manufacturing

Low pressure molding is a revolutionary plastic manufacturing process that offers a number of benefits for businesses. This process is becoming increasingly popular due to its ability to produce high-quality parts with minimal waste and cost.

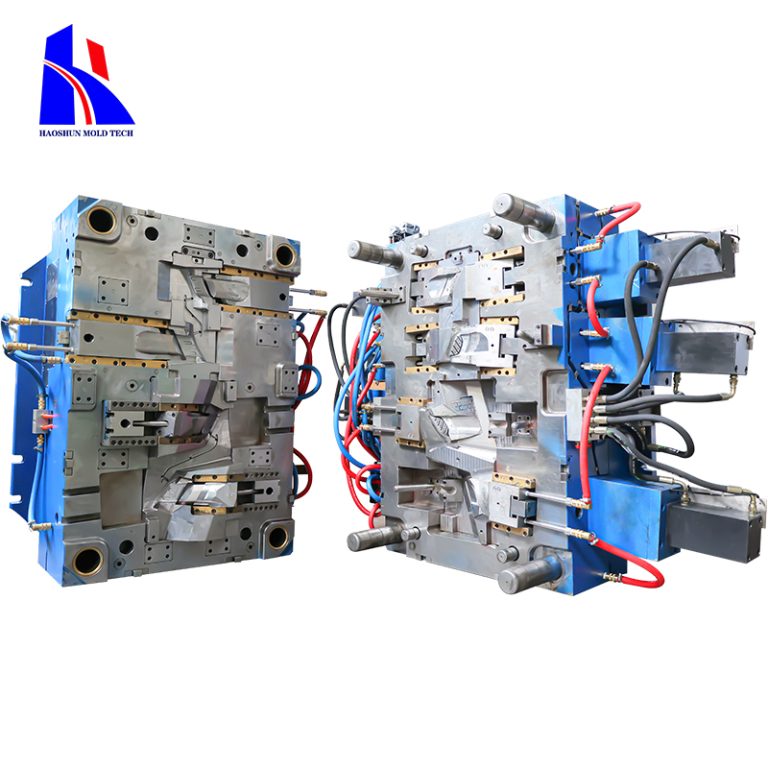

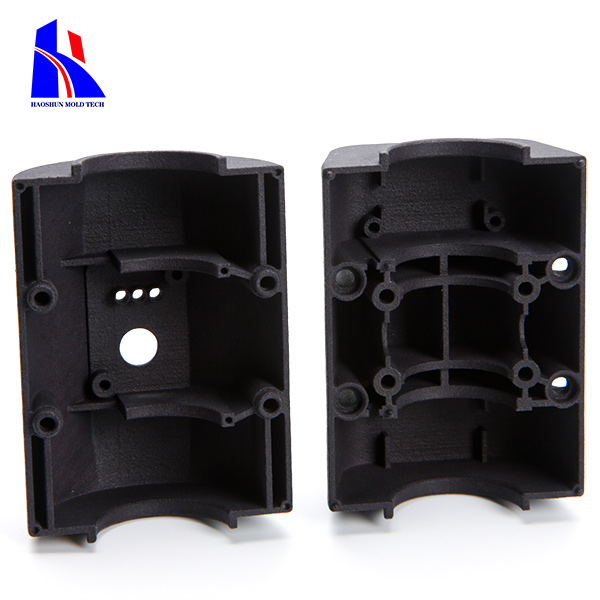

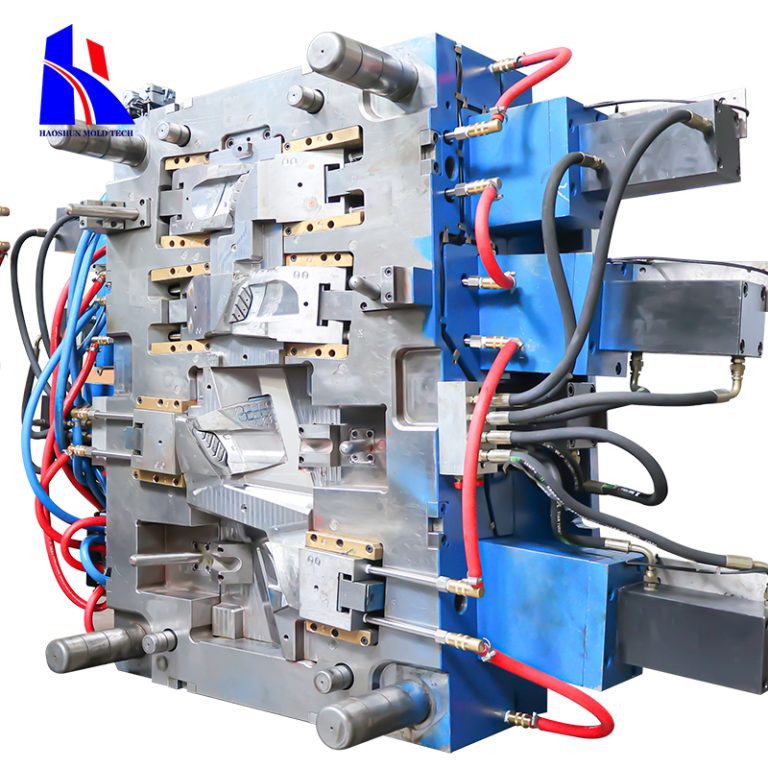

Low pressure molding is a process that uses a low-pressure injection system to inject molten plastic into a mold. This process is much less expensive than traditional injection molding and can produce parts with greater accuracy and detail. The low pressure also helps to reduce the risk of defects and warping, resulting in a higher quality product.

| Quality System | ISO 9001: 2015 |

| We Promise | Customer first , never for short-term profit, and sell long-term benefits |

| Our Services | ODM/ODM |

Another benefit of low pressure molding is that it is much faster than traditional injection molding. This process can produce parts in a fraction of the time, allowing businesses to get their products to market faster. Additionally, the low pressure process requires less energy and produces less waste, making it more environmentally friendly.

Finally, low pressure molding is much safer than traditional injection molding. The low pressure process eliminates the risk of high-pressure explosions, which can be dangerous for workers. Additionally, the process is much quieter than traditional injection molding, making it a better option for businesses that are located in residential areas.

Overall, low pressure molding is a great option for businesses looking to produce high-quality parts with minimal waste and cost. This process is faster, safer, and more environmentally friendly than traditional injection molding, making it an attractive option for businesses of all sizes.