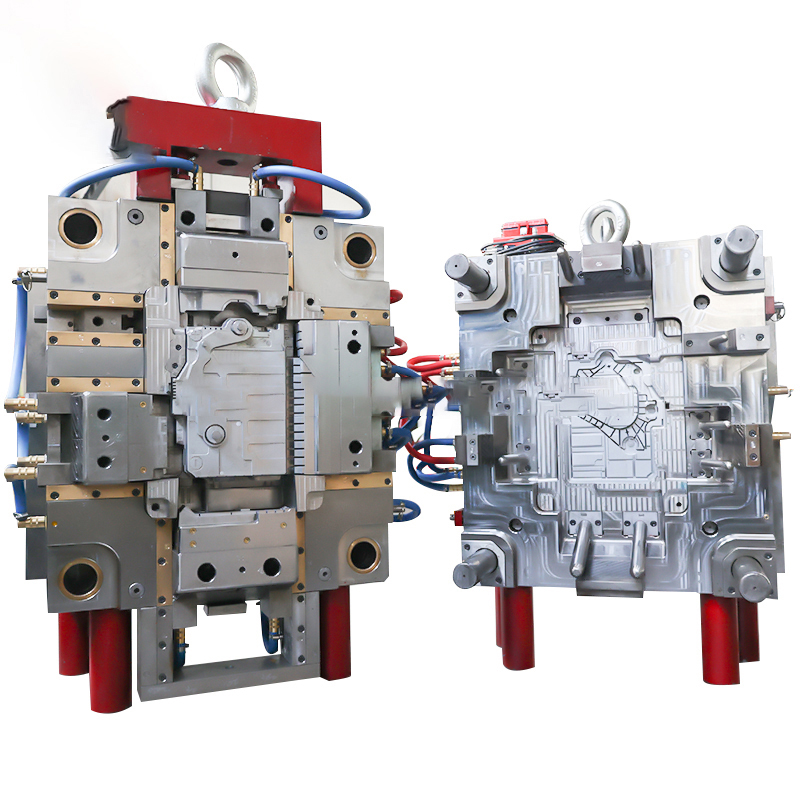

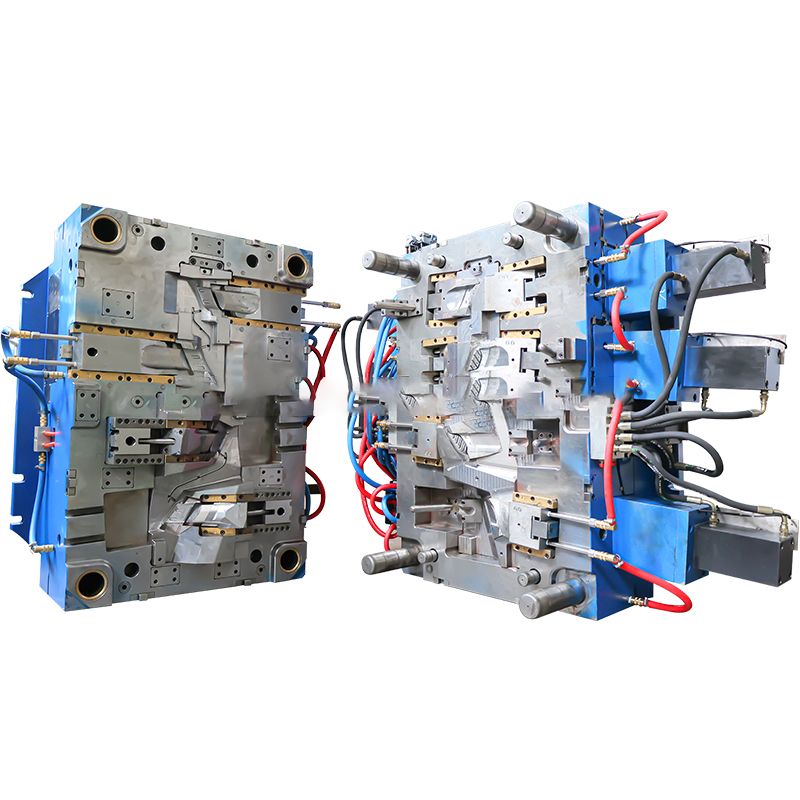

Production Tooling In Manufacturing

Hao Shun is proud to offer the finest tool-making and high-volume production services to support your most ambitious plastic injection molding projects. Our meticulous process control and positive material identification help ensure that millions of complex parts and assemblies can be made with consistent cycle times and the lowest possible cost per piece. We’re independently certified to ISO 9001, 16949, 14001 standards to ensure complete peace of mind.

What is Production Tooling in Manufacturing?

Production tooling refers to plastic injection molding tools and dies that are built to withstand the rigorous demands of mass production while maintaining tight dimensional tolerances on every finished part.

To do this successfully, tooling manufacturers must bring together the finest raw materials, advanced MoldFlow software, sophisticated tool design, and precision machining in order to build a production tool that can be cycled millions of times without degrading. Not every manufacturer is able to provide this level of experience or attention to detail.

Why Choose Hao Shun for Production Tooling Manufacturing?

Hao Shun stands apart from the competition by ofering a higher level of personalzed support for discering product design professionals working in advancedindustries. We’re also product designers,engineers, and manufacturing specialists who share your passion for excellence in workmanship. Here is why to considerStar Rapid as your strategic product development partner.

| Clear Communication | You will benefit from having experienced international managers and multilingual sales engineers around the world ensuring that your requirements for advanced high-volume production mold tools and finished parts are fully understood and effectively communicated throughout the organization. |

| Professional Expertise | Hao Shun has many years of experience working with Fortune 500companies, and we speak the languages of engineering and precisionmanufacturing. We’re proud to make complex production mold tools foradvanced automotive, aerospace, and medical applications. |

| Positive Material ldentification | Positive material identification is guaranteed using scientific test equipment.You get full material traceability so you can meet your critical product certification and licensing requirements. |

| Comprehensive Services | We offer a full suite of additional services to complete your project to the highest specifications. These include CNC milling and turning, aluminum extrusion, metal stamping, EDM machining, painting, plating, laser etching.light assembly, and more. |

Production Tooling Materials

There are many types of hardened and semi-hardened tool steels to choose from, including P20, NAK80, H13, and S136. They differ in the degree of corrosion resistance, toughness, thermal efficiency, and the ability to take a high polish.

That’s why the choice of tool material that’s best suited for your project depends on your intended production volume, the surface finish of the part, the type of resin that’s being injected, and the complexity of the tool design.

As with all tooling design decisions, we advise consulting with your manufacturing partner in advance to clearly understand your options.

Tooling Costs

It’s not possible to predict tooling costs in advance for any project. There are simply too many variables to consider. However, we can identify the main cost drivers:

Sophisticated production tools can be a significant initial investment, but for high-volume production, the important question is cycle times and cost-per-piece. If the tool is made correctly, then it can be cycled more quickly and last much longer, which saves money in the long run. That’s why we advise our clients not to worry about tool cost, but rather about tool quality and tool longevity.

Production Tooling FAQ

| When does it make sense to invest in family tools? | Family tools are the ideal solution for making a set of mismatched parts in a single cycle using a too with multiple cavities. We do this whenever a group of parts must have the same color so they can later be assembled into a finished product with a perfect match between all the pieces |

| Does overmolding work on every type of plastic substrate? | There are some substrates that don’t form a good bond with every elastomer. That’s why it’s important to work with the manufacturer to help find customsolutions for your particular application. |

| What is the difference between production and bridge tooling? | Bridge tooling is used to fill the production gap, between a handful of parts made with prototype tools on one side and millions of parts made with full production tools on the other, As such, bridge tooling typically will use less durable tool steel, will often forego automated sliders or hot runner systems, and will not use a secondary coating such as chrome plating or PVD. |

| How long does it take to make production tooling? | Depending on the complexity, after the CAD drawings are confirmed it an take several weeks to machine and heat treat production tooling, although every job will vary. |

Request Your Free Quote Today

Our improved AI algorithm decreases quotation times by up to 90%. Most quotes are delivered within 24 hrs, or faster, depending on project details and your needs. Your customer support partner will contact you directly to ensure you’ve received and understand all aspects of your quotation and to answer any questions you may have about the manufacturing process, the materials we use, your quote, and beyond!