plastic mold injection molding plant puts

Benefits of Implementing Plastic Mold Injection Molding in Your Plant

Plastic mold injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold cavity. This process is commonly used in various industries, including automotive, medical, and consumer goods. Implementing plastic mold injection molding in your plant can offer numerous benefits that can help improve efficiency, reduce costs, and enhance product quality.

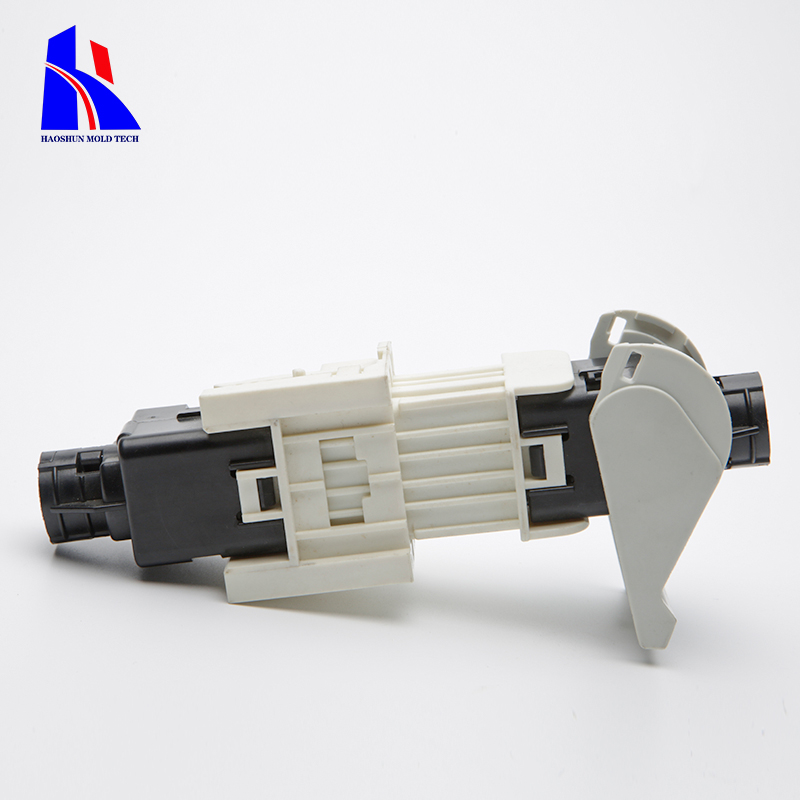

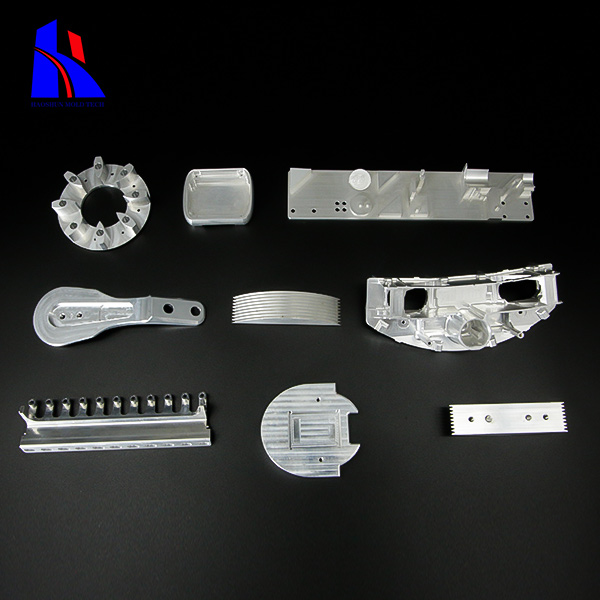

One of the key benefits of plastic mold injection molding is its ability to produce high-quality, complex parts with tight tolerances. The process allows for the production of intricate shapes and designs that would be difficult or impossible to achieve with other manufacturing methods. This can help you create products that stand out in the market and meet the demands of your customers.

Additionally, plastic mold injection molding is a highly efficient process that can help you reduce production time and costs. The process is automated, which means that it can run continuously without the need for constant supervision. This can help you increase your production output and meet tight deadlines. Furthermore, the use of molds in plastic injection molding helps minimize material waste, as the excess plastic can be recycled and reused in future production runs.

Another benefit of implementing plastic mold injection molding in your plant is the ability to produce consistent and repeatable parts. The use of molds ensures that each part is produced to the exact specifications, resulting in uniformity across all products. This can help you maintain a high level of quality control and ensure that your products meet the required standards.

Furthermore, plastic mold injection molding offers a high level of design flexibility, allowing you to easily make changes to your products without incurring significant costs. This can be particularly beneficial in industries where product designs are constantly evolving, as it allows you to quickly adapt to changing market demands and customer preferences.

In addition to these benefits, plastic mold injection molding is also a cost-effective manufacturing process. The initial investment in molds and equipment may be higher compared to other manufacturing methods, but the long-term savings can be significant. The high production output, reduced material waste, and minimal labor requirements can help you lower your overall production costs and improve your bottom line.

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Our Services | OEM/ODM |

Overall, implementing plastic mold injection molding in your plant can offer a wide range of benefits that can help you stay competitive in today’s fast-paced market. From producing high-quality, complex parts to reducing production time and costs, this manufacturing process can help you streamline your operations and deliver superior products to your customers. Consider incorporating plastic mold injection molding into your plant to take advantage of these benefits and stay ahead of the competition.