abs printing plastic parts

Table of Contents

How ABS Plastic 3D Printing is Revolutionizing the Manufacturing Industry

The manufacturing industry is undergoing a revolution, and it’s all thanks to ABS plastic 3D printing. This innovative technology is transforming the way products are made, allowing manufacturers to create complex designs with unprecedented speed and accuracy.

Take, for example, the story of a small business that needed to produce a custom-made part for a machine. In the past, this would have been a time-consuming and expensive process, requiring the business to outsource the job to a third-party manufacturer. But with ABS plastic 3D printing, the business was able to produce the part in-house, saving time and money.

The same technology is being used to create complex medical devices, such as prosthetics and implants. 3D printing allows for the creation of intricate designs that would be impossible to produce with traditional manufacturing methods. This has opened up a world of possibilities for medical professionals, allowing them to create custom-made devices that are tailored to the individual patient’s needs.

ABS plastic 3D printing is also being used to create consumer products, such as toys and gadgets. This technology allows manufacturers to quickly and easily produce complex designs, allowing them to bring new products to market faster than ever before.

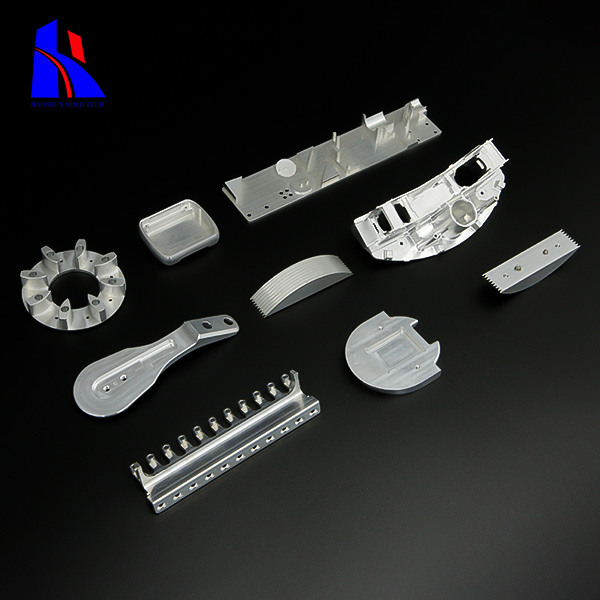

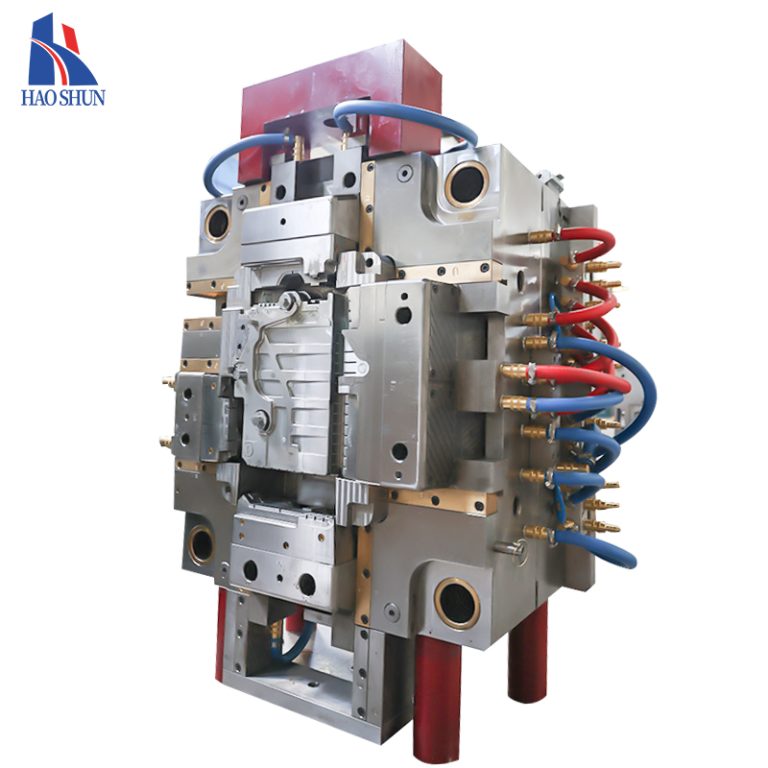

| Product Name | OEM Plastic injection molding Parts |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

The possibilities of ABS plastic 3D printing are truly endless, and it’s revolutionizing the manufacturing industry. This technology is allowing manufacturers to create complex designs with unprecedented speed and accuracy, opening up a world of possibilities for businesses and consumers alike.