casting cnc machining cnc casting

more details :

1.Design and CAD Modeling:

2.CAD Software: Used to design the part with high precision. The model includes details like dimensions, features, and tolerances.

3.Simulation: Some software allows for simulation of the casting process to identify potential issues before actual production.

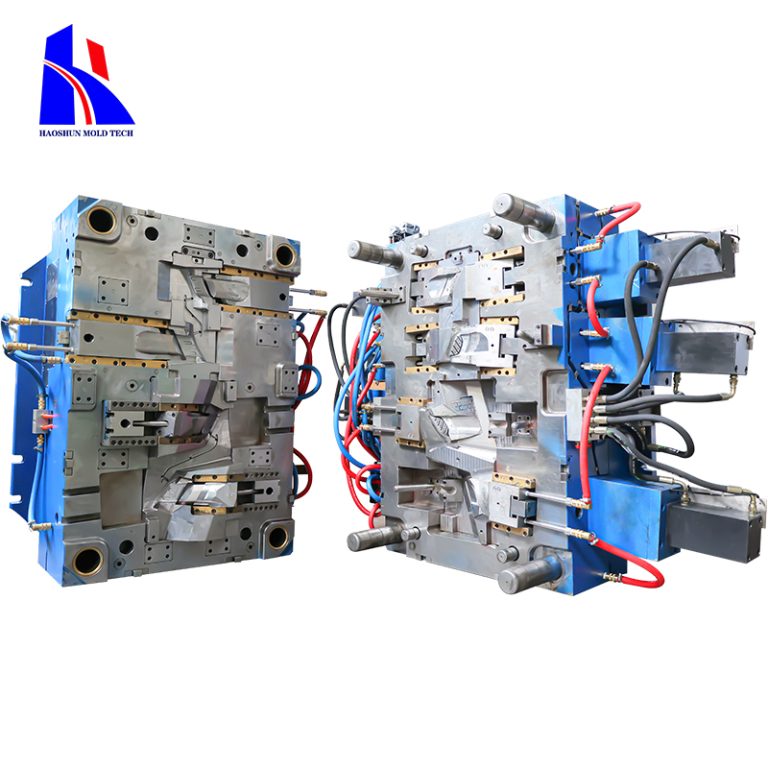

4.CNC Machining of the Mold:

5.Material Selection: Molds are often made from durable materials like steel or aluminum.

6.Machining Techniques: CNC machines use various techniques, such as milling and turning, to create detailed and accurate molds.

7.Complex Features: CNC machining can produce intricate mold features, including cooling channels and complex geometries.

8.Casting:

9.Types of Casting:

10.Sand Casting: Uses a sand mold and is cost-effective for large or complex parts.

11.Investment Casting: Involves a wax model and produces parts with high precision and smooth surface finishes.

12.Die Casting: Utilizes high-pressure to force molten metal into a mold, suitable for high-volume production.

13.Material Preparation: Metals or other materials are melted and poured into the mold.

14.Cooling and Solidification:

15.Controlled Cooling: Ensures uniform solidification to prevent defects like warping or cracking.

16.Time Considerations: Cooling time varies based on material and part size.

17.Post-Casting CNC Machining:

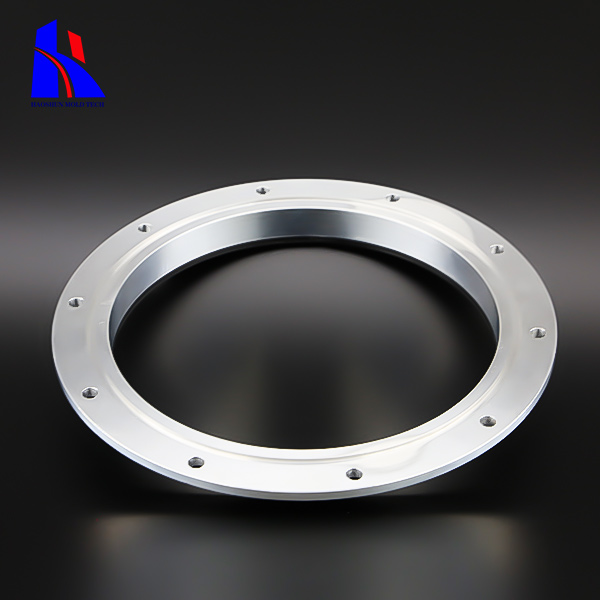

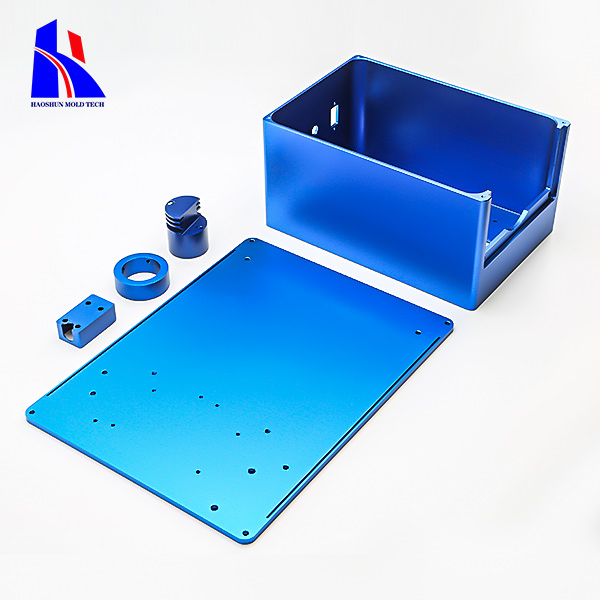

18.Deburring and Cleaning: Removal of any casting remnants or imperfections.

19.Precision Machining: CNC machines refine the part to meet exact specifications, such as tight tolerances and high surface finish.

20.Inspection: Parts are often inspected using precision tools to ensure they meet quality standards.

This detailed approach enhances the accuracy and functionality of the final product, combining the strengths of both casting and CNC machining.

email : shine@haoshuntech.com

telephone: +8613560008062