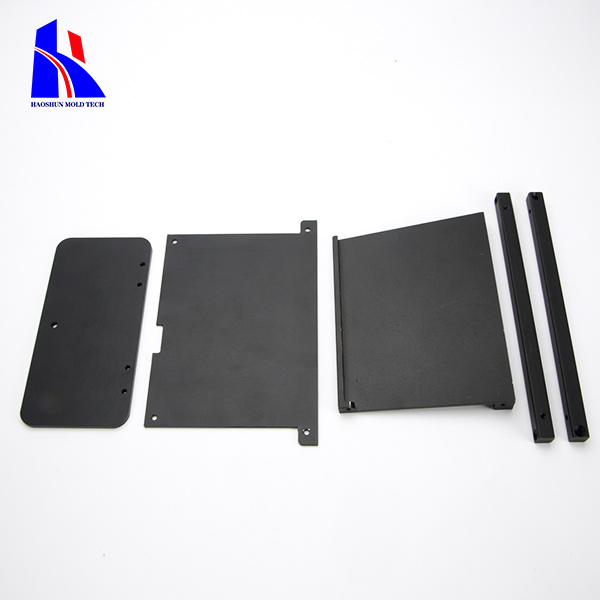

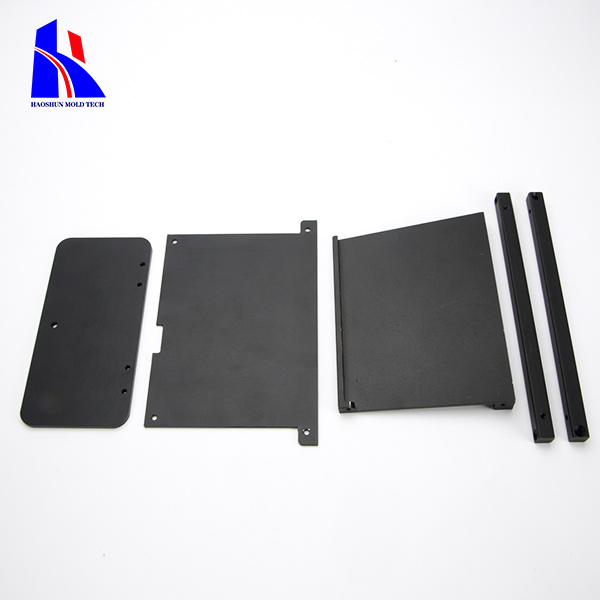

cnc part prototype

Table of Contents

The Benefits of CNC Part Prototype Manufacturing

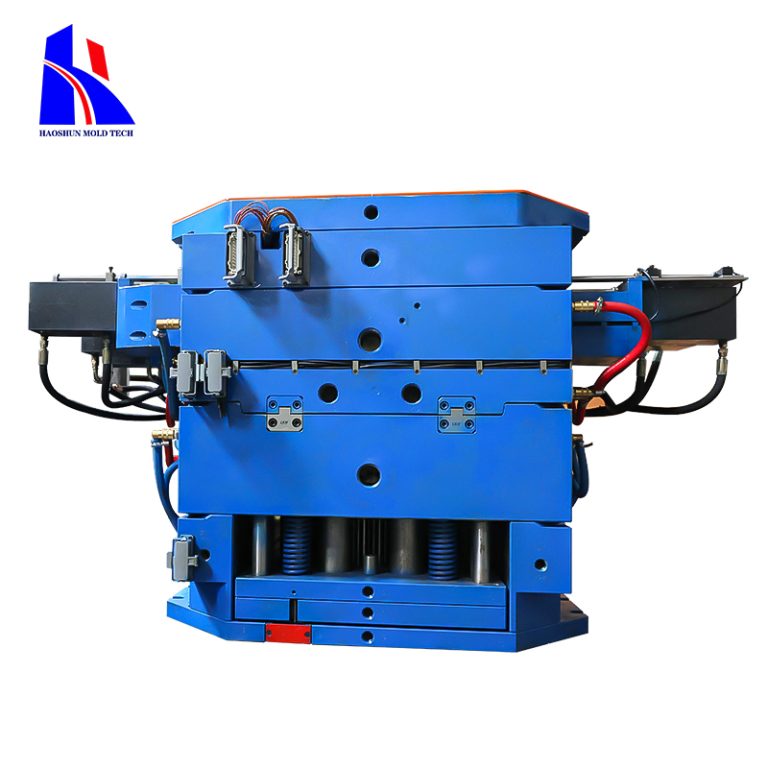

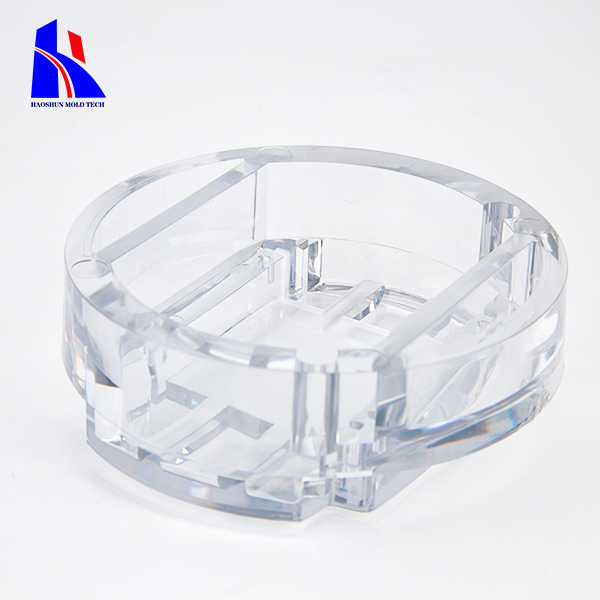

CNC part prototype manufacturing is a powerful tool for businesses that need to create custom parts quickly and accurately. With the help of CNC machines, businesses can create prototypes of parts that are ready for production in a fraction of the time it would take to create them manually. This technology has revolutionized the way businesses create parts, and the benefits of CNC part prototype manufacturing are numerous.

First and foremost, CNC part prototype manufacturing is incredibly fast. With the help of CNC machines, businesses can create parts in a fraction of the time it would take to create them manually. This means that businesses can get their products to market faster, allowing them to stay ahead of the competition. Additionally, CNC machines are incredibly precise, meaning that businesses can create parts that are accurate to within a few thousandths of an inch. This level of precision is essential for creating parts that are safe and reliable.

Another benefit of CNC part prototype manufacturing is that it is cost-effective. CNC machines are relatively inexpensive to purchase and maintain, and they can be used to create parts in large quantities. This means that businesses can save money on production costs, allowing them to pass the savings on to their customers. Additionally, CNC machines are incredibly versatile, meaning that businesses can create a wide variety of parts with the same machine. This versatility allows businesses to create parts for a variety of applications, making them more competitive in the marketplace.

Finally, CNC part prototype manufacturing is incredibly safe. CNC machines are designed to be incredibly precise, meaning that they can create parts without the risk of human error. This means that businesses can create parts that are safe and reliable, without the risk of injury or damage to the parts. Additionally, CNC machines are incredibly easy to use, meaning that businesses can quickly and easily create parts without the need for extensive training.

| Drawing Formats | 2D(PDF/CAD) And 3D(STP / STEP) |

| Materials | Aluminum / Stainless Steel / Steel / Brass / Copper / Plastic / Iron / Alloy / Zinc / Etc. Other Special Materials:Nylon/Titanium/Lucite/Etc. |

| Main Process | CNC Turning / Milling / Drilling / Bushing / Auto Lathe / Surface Treatment / Etc. |

CNC part prototype manufacturing is an incredibly powerful tool for businesses that need to create custom parts quickly and accurately. With the help of CNC machines, businesses can create parts in a fraction of the time it would take to create them manually, and they can do so with incredible precision and safety. Additionally, CNC machines are incredibly cost-effective, allowing businesses to save money on production costs. With the help of CNC part prototype manufacturing, businesses can stay ahead of the competition and create parts that are safe and reliable.

How to Choose the Right CNC Part Prototype Manufacturer for Your Project

When it comes to finding the right CNC part prototype manufacturer for your project, it can be a daunting task. With so many options available, it can be difficult to know which one is the best fit for your needs. However, with a few simple tips, you can make sure you choose the right CNC part prototype manufacturer for your project.

First, consider the type of CNC part prototype you need. Different manufacturers specialize in different types of CNC parts, so it’s important to find one that can meet your specific requirements. Do you need a prototype for a complex part or a simple one? Do you need a prototype for a large-scale production run or a small-scale one? Knowing the answers to these questions will help you narrow down your options.

Second, consider the experience and expertise of the CNC part prototype manufacturer. Look for a manufacturer that has a proven track record of producing high-quality prototypes. Ask for references and read customer reviews to get a better idea of the manufacturer’s capabilities.

Third, consider the cost of the CNC part prototype. Different manufacturers offer different prices, so it’s important to compare prices to make sure you’re getting the best deal. Don’t be afraid to negotiate with the manufacturer to get the best price possible.

Finally, consider the turnaround time of the CNC part prototype. Different manufacturers have different turnaround times, so it’s important to find one that can meet your timeline. Ask the manufacturer how long it will take to produce the prototype and make sure it fits within your timeline.

By following these tips, you can make sure you choose the right CNC part prototype manufacturer for your project. With the right manufacturer, you can be sure that your project will be completed on time and within budget. So don’t be afraid to take the time to find the right CNC part prototype manufacturer for your project. With the right manufacturer, you can be sure that your project will be a success.