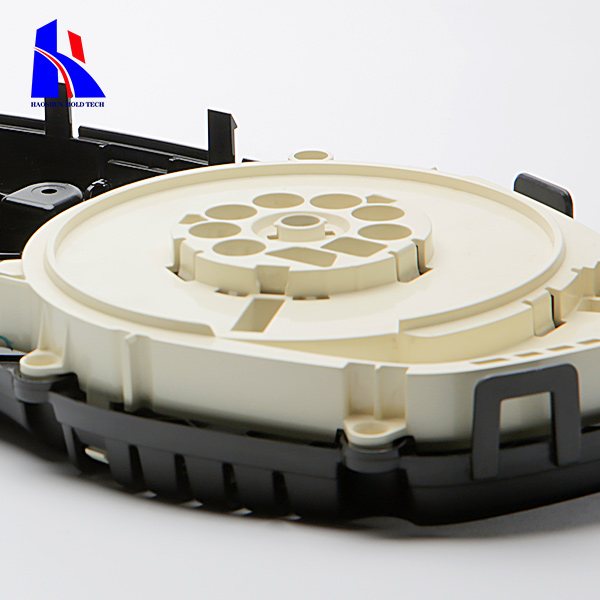

custom plastic mold

The Benefits of Using Custom Plastic Molds in Manufacturing Processes

The manufacturing industry is constantly evolving, with new technologies and techniques being developed to improve efficiency and productivity. One such innovation is the use of custom plastic molds in manufacturing processes. Custom plastic molds offer a range of benefits that can greatly enhance the production process and result in high-quality products.

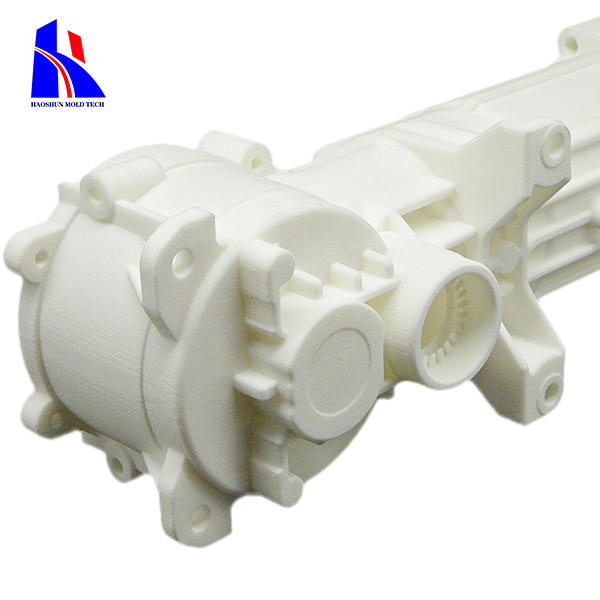

One of the key advantages of using custom plastic molds is the ability to create complex and intricate designs. Traditional manufacturing methods often have limitations when it comes to producing intricate shapes and designs. However, with custom plastic molds, manufacturers can create highly detailed and complex parts with ease. This opens up a world of possibilities for designers and engineers, allowing them to push the boundaries of what is possible in terms of product design.

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

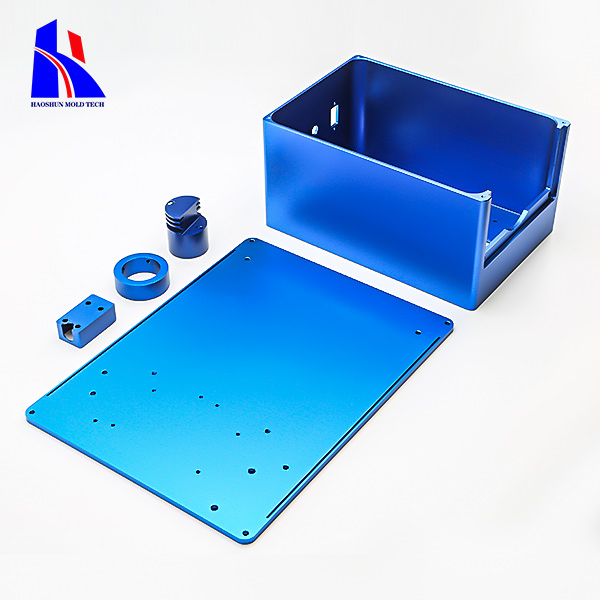

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

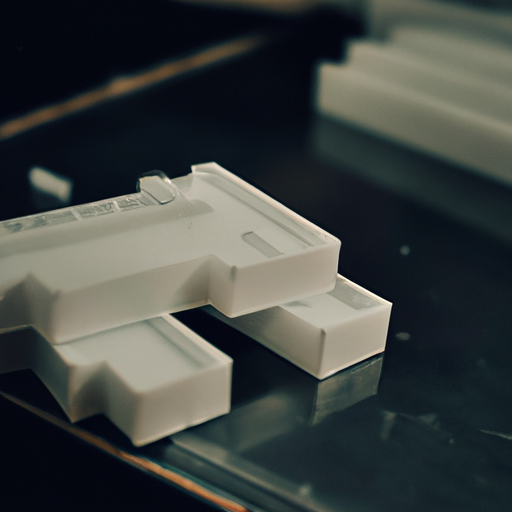

Another benefit of using custom plastic molds is the cost-effectiveness it offers. Traditional manufacturing methods often require the production of expensive and time-consuming molds for each individual part. This can be a significant investment, especially for small businesses or startups. However, with custom plastic molds, manufacturers can create multiple parts using a single mold, reducing costs and increasing efficiency. This not only saves money but also allows for faster production times, enabling businesses to meet customer demands more effectively.

Custom plastic molds also offer a high level of precision and accuracy. The molds are designed using advanced computer-aided design (CAD) software, ensuring that each part is manufactured to exact specifications. This level of precision is crucial in industries such as aerospace and medical, where even the smallest deviation can have serious consequences. By using custom plastic molds, manufacturers can ensure that each part is produced with the utmost accuracy, resulting in high-quality products that meet the strictest industry standards.

In addition to precision, custom plastic molds also offer a high level of repeatability. Once a mold is created, it can be used repeatedly to produce identical parts. This is particularly beneficial for businesses that require large quantities of the same part. By using custom plastic molds, manufacturers can ensure that each part is consistent in terms of size, shape, and quality. This not only improves the overall quality of the product but also reduces the likelihood of defects or inconsistencies.

Furthermore, custom plastic molds offer a high level of flexibility. Manufacturers can easily modify or update the design of the mold to accommodate changes in product specifications or customer requirements. This allows for greater adaptability and responsiveness, ensuring that businesses can quickly respond to market demands and stay ahead of the competition.

In conclusion, the use of custom plastic molds in manufacturing processes offers a range of benefits. From the ability to create complex designs to cost-effectiveness and precision, custom plastic molds are revolutionizing the manufacturing industry. By utilizing these molds, businesses can produce high-quality products that meet the strictest industry standards, while also improving efficiency and reducing costs. With the ever-increasing demand for innovative and high-quality products, custom plastic molds are becoming an essential tool for manufacturers looking to stay competitive in today’s fast-paced market.