injection molding for plastic chair

Benefits of Injection Molding for Plastic Chair Manufacturing

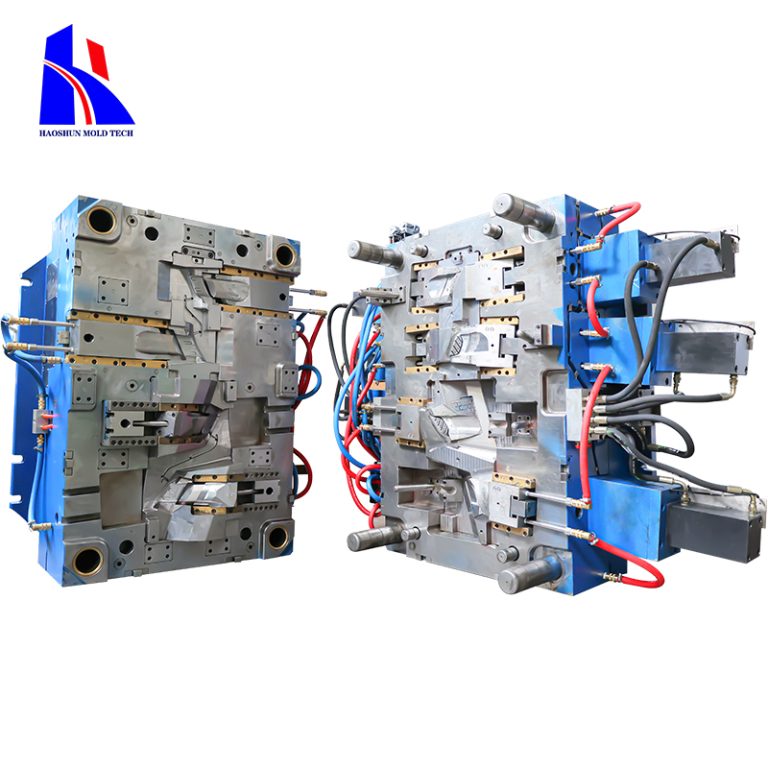

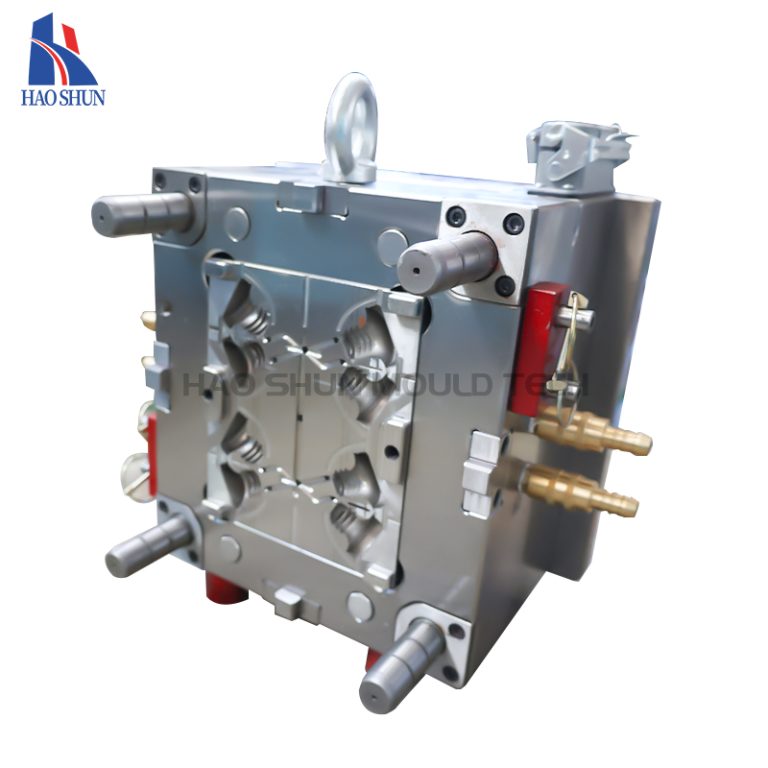

Injection molding is a widely used manufacturing process for producing plastic products, including chairs. This process involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. Injection molding offers several benefits for plastic chair manufacturing, making it a popular choice for producing high-quality and cost-effective chairs.

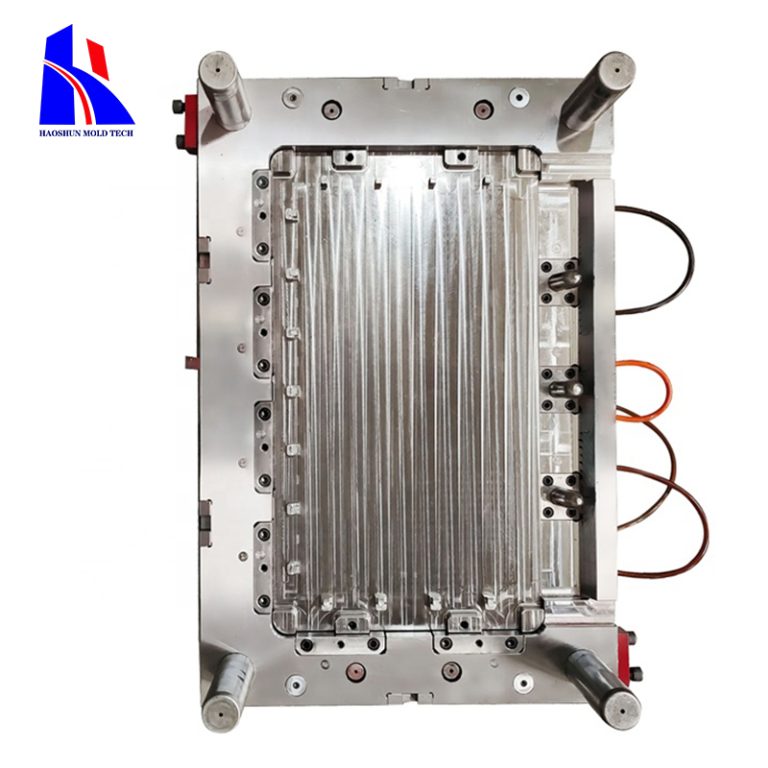

One of the key advantages of injection molding for plastic chair manufacturing is its ability to produce complex and intricate designs with high precision. The mold cavity can be customized to create chairs with intricate details, curves, and patterns that would be difficult or impossible to achieve with other manufacturing processes. This allows for greater design flexibility and creativity in producing unique and visually appealing chairs.

Another benefit of injection molding is its high production efficiency and speed. Once the mold is set up, the injection molding process can produce a large number of chairs in a relatively short amount of time. This high production efficiency helps to reduce manufacturing costs and lead times, making injection molding a cost-effective option for producing plastic chairs in large quantities.

Injection molding also offers consistent and repeatable results, ensuring that each chair produced is of the same high quality. The automated nature of the injection molding process helps to minimize human error and variability, resulting in chairs that meet strict quality standards and specifications. This consistency is essential for maintaining brand reputation and customer satisfaction in the competitive furniture market.

Furthermore, injection molding is a highly versatile process that can accommodate a wide range of plastic materials, colors, and finishes. This versatility allows manufacturers to produce chairs in different styles, colors, and textures to meet the diverse preferences of consumers. Whether it’s a sleek and modern design or a classic and traditional look, injection molding can deliver chairs that cater to various tastes and trends in the market.

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

| Our Services | OEM/ODM |

In addition to its design flexibility and production efficiency, injection molding is also a sustainable manufacturing process for plastic chairs. The use of recyclable plastic materials and the ability to recycle scrap and excess material make injection molding an environmentally friendly option for chair production. By reducing waste and energy consumption, manufacturers can minimize their environmental impact and contribute to a more sustainable future.

Overall, injection molding offers numerous benefits for plastic chair manufacturing, including design flexibility, production efficiency, consistent quality, versatility, and sustainability. These advantages make injection molding a preferred choice for producing high-quality and cost-effective chairs that meet the demands of the modern furniture market. Whether it’s for residential, commercial, or outdoor use, injection molding can deliver chairs that combine style, comfort, and durability for a wide range of applications. With its proven track record and ongoing advancements in technology, injection molding continues to be a leading manufacturing process for plastic chairs in the furniture industry.