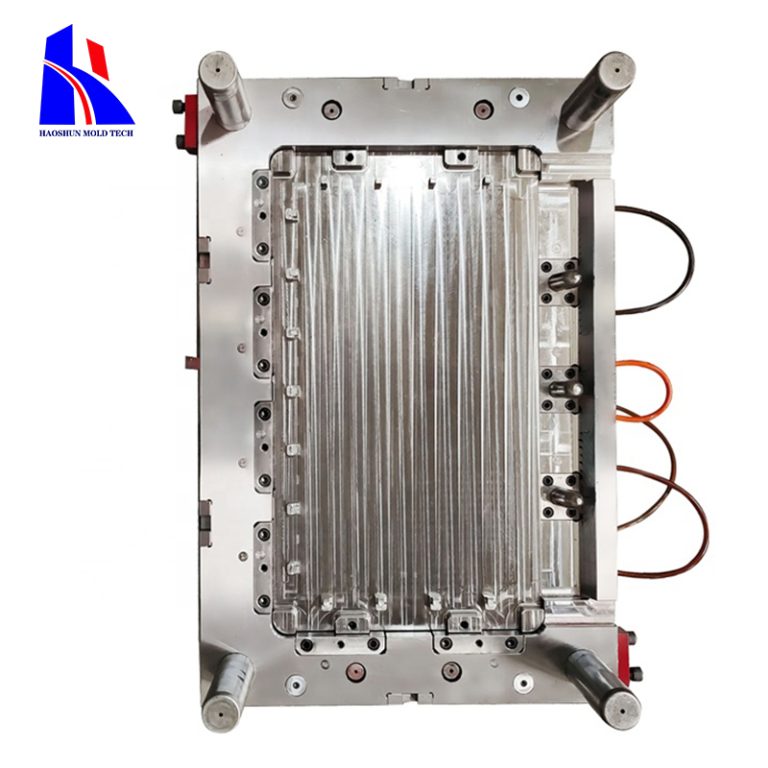

low price small plastic injection molding

Benefits of Low Price Small Plastic Injection Molding for Small Businesses

Small businesses often face challenges when it comes to manufacturing their products. Limited budgets and resources can make it difficult to compete with larger companies. However, low price small plastic injection molding can be a game-changer for these businesses. This manufacturing process offers numerous benefits that can help small businesses thrive in the competitive market.

One of the key advantages of low price small plastic injection molding is its cost-effectiveness. Traditional manufacturing methods can be expensive, especially for small production runs. However, plastic injection molding allows for high-volume production at a fraction of the cost. The initial investment in molds may seem daunting, but the long-term savings are significant. Small businesses can produce large quantities of products without breaking the bank, making it easier to meet customer demands and increase profitability.

In addition to cost savings, small plastic injection molding offers fast turnaround times. Traditional manufacturing methods often involve lengthy lead times, which can delay product launches and hinder business growth. With plastic injection molding, small businesses can reduce production time significantly. The process is highly automated, allowing for efficient and continuous production. This means that small businesses can quickly respond to market demands and stay ahead of the competition.

| Product Name | OEM Plastic injection molding Parts |

| Quotation | According to your drawing (material / Size / Required Technology / Etc.) |

Furthermore, low price small plastic injection molding offers exceptional precision and consistency. The molds used in this process are designed with intricate details, ensuring that each product is manufactured with precision. This level of accuracy is crucial for small businesses that rely on quality to build a strong reputation. Consistency is also a key factor in customer satisfaction. With plastic injection molding, small businesses can produce identical products with minimal variation, ensuring that customers receive the same high-quality item every time.

Another benefit of low price small plastic injection molding is its versatility. This manufacturing process can produce a wide range of products, from small components to larger items. Small businesses can leverage this versatility to diversify their product offerings and cater to different market segments. Whether it’s producing custom parts or creating unique consumer products, plastic injection molding provides the flexibility needed to meet various customer demands.

Moreover, small plastic injection molding is environmentally friendly. The process generates minimal waste, as excess plastic can be recycled and reused. This not only reduces the environmental impact but also helps small businesses save on material costs. Additionally, the energy consumption of plastic injection molding is relatively low compared to other manufacturing methods, making it a sustainable choice for small businesses looking to reduce their carbon footprint.

In conclusion, low price small plastic injection molding offers numerous benefits for small businesses. Its cost-effectiveness, fast turnaround times, precision, consistency, versatility, and environmental friendliness make it an attractive option for small businesses looking to compete in the market. By leveraging this manufacturing process, small businesses can produce high-quality products at a fraction of the cost, meet customer demands efficiently, and establish a strong reputation. With its many advantages, low price small plastic injection molding is a valuable tool for small businesses striving for success.