mist sprayer molding service plastic injection

Benefits of Using Mist Sprayer Molding Service for Plastic Injection

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process is commonly used to produce a wide range of plastic products, including mist sprayers. Mist sprayers are commonly used in various industries, such as cosmetics, pharmaceuticals, and household cleaning products. They are designed to deliver a fine mist of liquid, making them ideal for applications where precise and controlled dispensing is required.

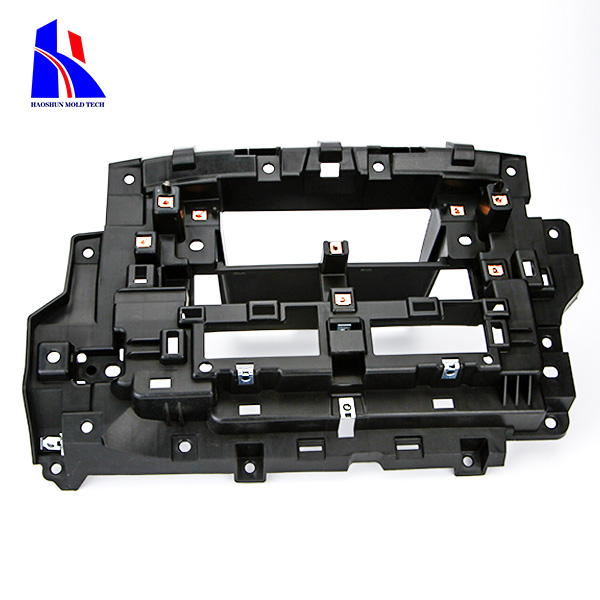

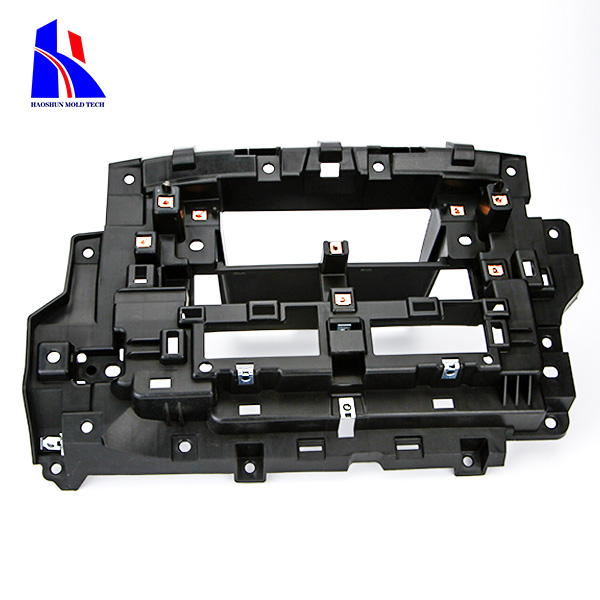

One of the key benefits of using mist sprayer molding service for plastic injection is the ability to produce high-quality, precision parts. Mist sprayers require tight tolerances to ensure proper functioning, and plastic injection molding is well-suited for achieving these tight tolerances. The molds used in plastic injection molding are highly precise, allowing for the production of consistent and accurate parts. This level of precision is essential for mist sprayers, as any deviation in dimensions can affect the performance of the sprayer.

Another benefit of using mist sprayer molding service for plastic injection is the ability to produce complex geometries. Mist sprayers often have intricate designs with multiple components that need to fit together seamlessly. Plastic injection molding allows for the production of complex geometries with ease, making it possible to create intricate designs that would be difficult or impossible to achieve with other manufacturing processes. This flexibility in design is a significant advantage for mist sprayer manufacturers looking to differentiate their products in a competitive market.

In addition to precision and complexity, plastic injection molding offers cost-effective production of mist sprayers. The initial tooling costs for plastic injection molding can be high, but once the molds are created, the cost per part decreases significantly. This cost efficiency is particularly beneficial for high-volume production runs, where the cost per part can be minimized through economies of scale. By using mist sprayer molding service for plastic injection, manufacturers can produce large quantities of mist sprayers at a lower cost per unit, making it a cost-effective solution for mass production.

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

Furthermore, plastic injection molding is a highly efficient manufacturing process that allows for fast production cycles. Once the molds are created, the injection molding process itself is relatively quick, with parts being produced in a matter of seconds or minutes. This rapid production cycle is advantageous for mist sprayer manufacturers who need to meet tight deadlines or respond quickly to changes in demand. By using mist sprayer molding service for plastic injection, manufacturers can streamline their production processes and bring products to market faster.

Overall, the benefits of using mist sprayer molding service for plastic injection are numerous. From precision and complexity to cost efficiency and speed, plastic injection molding offers a range of advantages for mist sprayer manufacturers. By leveraging the capabilities of plastic injection molding, manufacturers can produce high-quality mist sprayers that meet the demands of their customers and stand out in a competitive market.