OEM ODM Plastic Injection Molding Parts

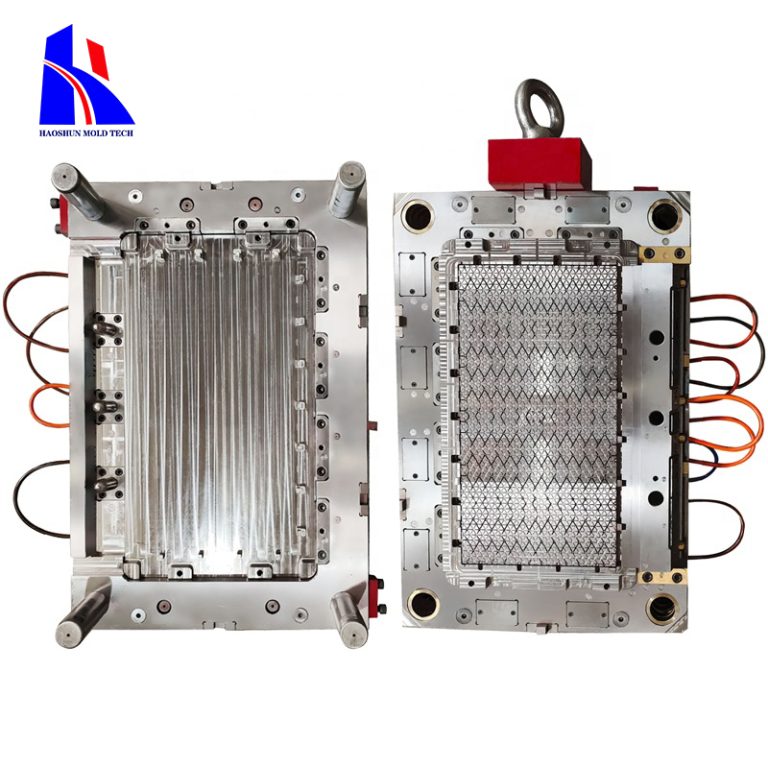

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services for plastic injection molding parts involve custom designing and manufacturing components based on specific requirements. These services are commonly provided by companies specializing in plastic injection molding. Here are some key points regarding OEM and ODM plastic injection molding parts:

1.OEM Services:

2.Custom Manufacturing: OEM services involve producing components as per the client’s specifications or designs. The manufacturer will strictly follow the client’s requirements, including design, material selection, and specifications.

3.Brand Incorporation: OEM products are typically sold under the client’s brand name or logo. The manufacturer acts as a supplier, producing goods based on the client’s OEM agreement.

4.Quality Control: OEM services often include stringent quality control measures to ensure that the manufactured parts meet the required standards and specifications.

5.ODM Services:

6.Design and Development: ODM services go a step further by providing design and development expertise. The manufacturer designs products based on the client’s general requirements or concept. This allows clients to focus on marketing and distribution.

7.Customization Options: ODM services offer some degree of customization to suit client needs while leveraging the manufacturer’s design capabilities and expertise.

8.Exclusive Designs: ODM products are usually unique and may not be available elsewhere, as the manufacturer retains design ownership.

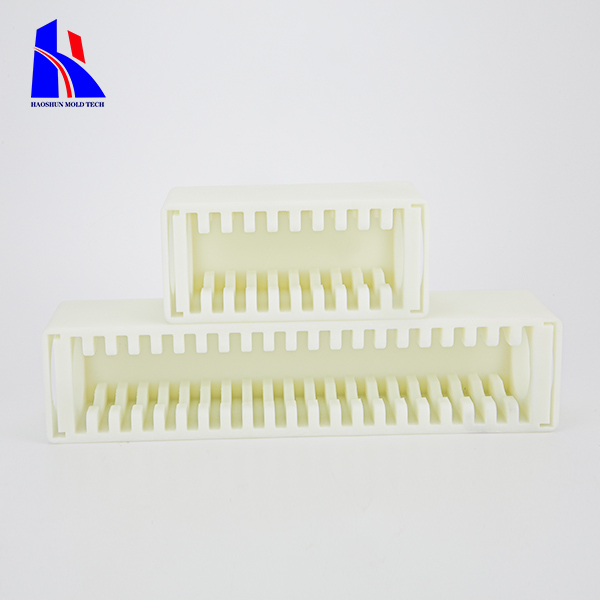

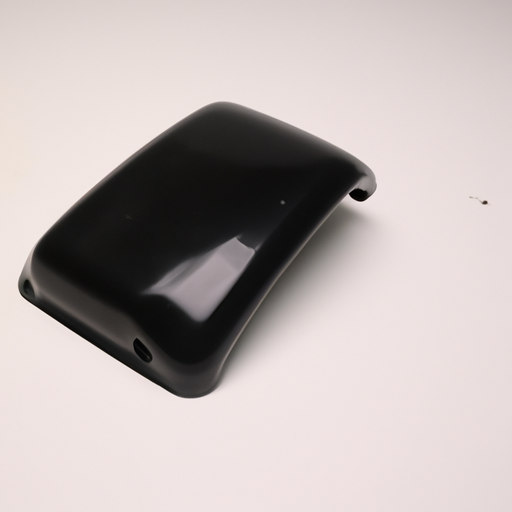

9.Plastic Injection Molding Parts:

10.Material Selection: Plastic injection molding offers a wide range of material options, including various types of plastics with different properties such as strength, flexibility, and heat resistance.

11.Customization: OEM and ODM services allow for customization of plastic parts in terms of size, shape, color, and functionality to meet specific project requirements.

12.Quality Assurance: Reputable manufacturers ensure high-quality standards in the molding process, from tooling design to final inspection, to deliver parts that meet or exceed customer expectations.

13.Benefits:

14.Cost Efficiency: OEM and ODM services can help streamline production processes and reduce costs by leveraging the manufacturer’s expertise and infrastructure.

15.Time Efficiency: Working with experienced manufacturers can shorten lead times and accelerate product development cycles.

16.Scalability: OEM and ODM services are often scalable, allowing clients to adjust production volumes based on demand fluctuations.

When seeking OEM or ODM plastic injection molding parts, it’s essential to collaborate with a reliable and experienced manufacturer that can deliver high-quality, customized components tailored to your specific requirements.