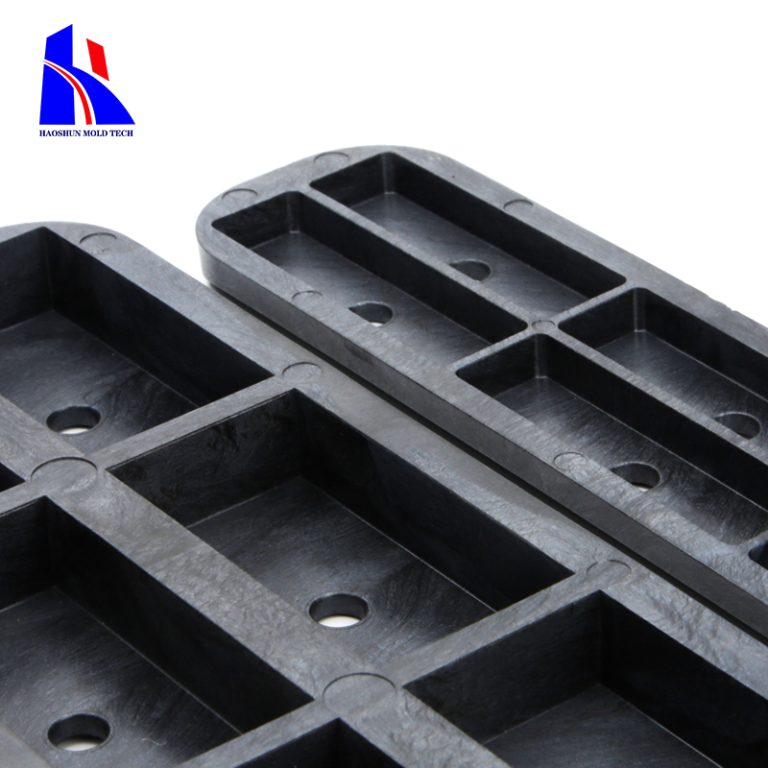

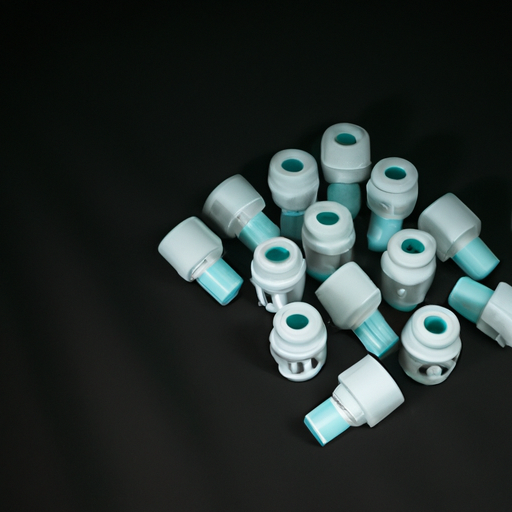

plastic container supplier custom small plastic part

When looking for a plastic container supplier that can customize small plastic parts, you’ll need to consider several factors to ensure you find a provider that meets your needs. Here’s a detailed guide to help you through the process:

- Define Your Requirements

a. Type of Plastic Part:

1.Functionality: What will the part be used for? (e.g., packaging, storage, components for machinery)

2.Design Features: Do you need specific shapes, sizes, or functionalities?

3.Tolerance and Precision: How precise does the part need to be? Are there specific tolerances that must be met?

b. Material:

4.Plastic Type: Common options include polyethylene (PE), polypropylene (PP), polycarbonate (PC), and acrylonitrile butadiene styrene (ABS). The choice of material depends on the part’s application, strength requirements, and environmental conditions.

5.Properties: Consider factors like durability, chemical resistance, flexibility, or transparency.

c. Size and Quantity:

6.Dimensions: What are the exact measurements and tolerances for the part?

7.Production Volume: Are you looking for a large production run or just a few prototypes?

- Find Potential Suppliers

a. Search Online:

8.Directories and Platforms: Websites like ThomasNet, Alibaba, and Made-in-China can help you find suppliers.

9.Industry-Specific Sites: Look for suppliers specializing in plastic manufacturing and custom molding.

b. Local Suppliers:

10.Trade Shows and Exhibitions: Attend industry events to meet potential suppliers.

11.Business Directories: Check local business directories or chambers of commerce.

c. Referrals and Reviews:

12.Industry Contacts: Ask for recommendations from industry peers.

13.Customer Reviews: Look for reviews and testimonials to gauge the reliability and quality of the suppliers.

- Evaluate Suppliers

a. Capabilities:

14.Technology: Ensure they have the necessary machinery and technology for your part (e.g., injection molding, blow molding).

15.Experience: Check their experience with similar projects or materials.

b. Quality Control:

16.Certifications: Look for quality certifications like ISO 9001.

17.Testing: Ask about their quality control processes and testing procedures.

c. Lead Times and Pricing:

18.Quotes: Request detailed quotes that include production costs, setup fees, and shipping.

19.Delivery Time: Check the lead times for prototypes and production runs.

- Discuss Customization Details

a. Prototypes:

20.Initial Samples: Ask for prototypes to evaluate the design and functionality before committing to full production.

21.Adjustments: Be prepared to make design changes based on prototype evaluations.

b. Design Files:

22.Format: Ensure your design files are in a compatible format (e.g., CAD files).

23.Collaboration: Work closely with the supplier’s design team to refine your part.

- Finalize and Place Orders

a. Contract and Agreements:

24.Terms and Conditions: Clearly outline the terms of production, delivery schedules, and payment terms.

25.Intellectual Property: Ensure agreements on IP rights and confidentiality if applicable.

b. Order Placement:

26.Production Run: Place your order based on the agreed terms and ensure you receive order confirmations and progress updates.

- Post-Production Support

a. Quality Assurance:

27.Inspection: Verify that the final parts meet your specifications and quality standards.

28.Feedback: Provide feedback to the supplier for any necessary adjustments or improvements.

b. After-Sales Support:

29.Support: Ensure the supplier offers support for any issues or defects that arise.

By following these detailed steps, you can effectively find and work with a plastic container supplier that can customize small plastic parts to meet your specific needs.

email : shine@haoshuntech.com

telephone: +8613560008062