plastic mold make

Table of Contents

The Benefits of Using Plastic Mold Making for Your Manufacturing Process

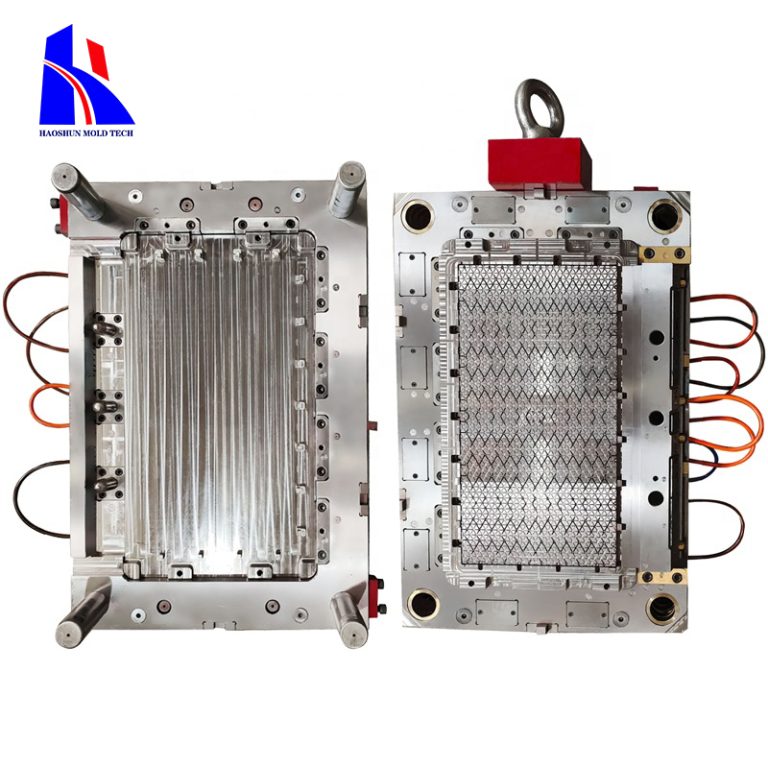

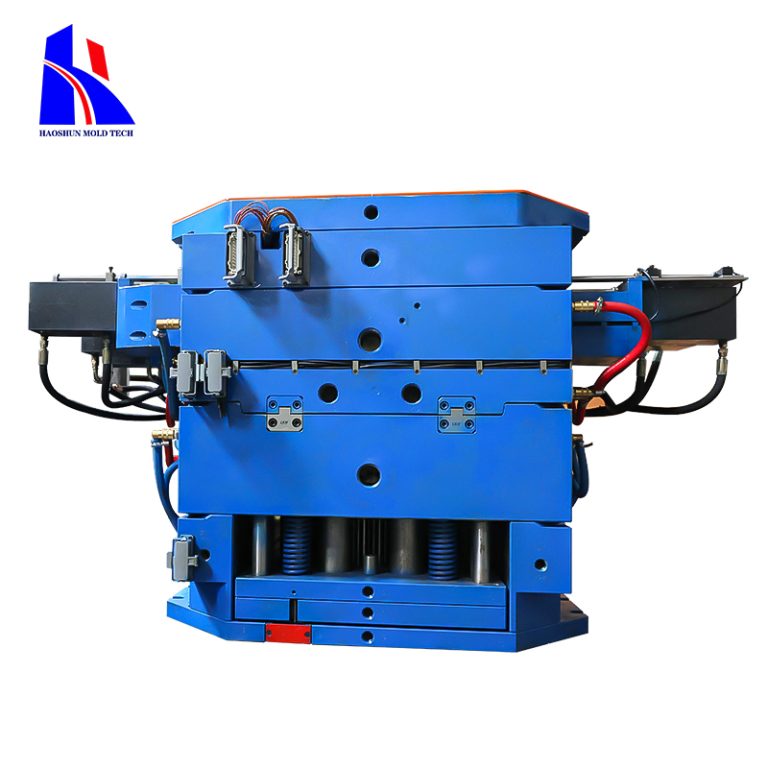

Plastic mold making is a popular manufacturing process used to create a variety of products, from toys to medical devices. This process involves creating a mold from a plastic material, such as polyethylene or polypropylene, and then using it to form the desired product. Plastic mold making offers a number of advantages over other manufacturing processes, making it an ideal choice for many applications.

| Product name | Plastic Injection Mould |

| Mould Base | SD,LKM Standard, HASCO Standard Self-made, etc. |

One of the primary benefits of plastic mold making is its cost-effectiveness. Plastic molds are relatively inexpensive to produce, and they can be reused multiple times, reducing the cost of production. Additionally, plastic molds can be produced quickly, allowing for shorter lead times and faster production.

Another advantage of plastic mold making is its versatility. Plastic molds can be used to create a wide variety of products, from simple toys to complex medical devices. This versatility allows manufacturers to create products that meet their exact specifications. Additionally, plastic molds can be used to create products with intricate details, such as textured surfaces or intricate patterns.

Finally, plastic mold making is a relatively safe process. The materials used in the process are non-toxic and non-flammable, making it a safe choice for many applications. Additionally, plastic molds can be produced with a variety of safety features, such as air vents and pressure relief valves, to ensure the safety of the product.

Overall, plastic mold making is an efficient and cost-effective manufacturing process that offers a number of advantages. It is versatile, cost-effective, and safe, making it an ideal choice for many applications.