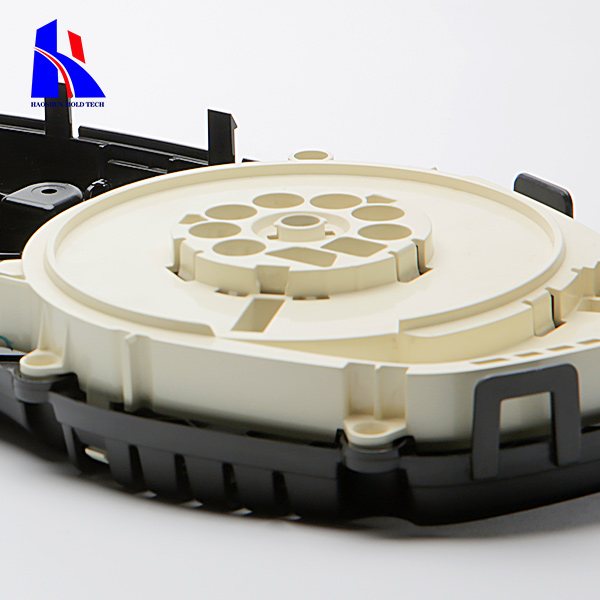

plastic parts for carmount holders plastic parts

When designing or selecting plastic parts for car mount holders, there are several key factors and materials to consider:

- Material Selection

1.ABS (Acrylonitrile Butadiene Styrene): Known for its toughness and impact resistance. It’s often used in automotive parts because it can withstand vibrations and impacts.

2.Polycarbonate: Offers high impact resistance and durability, making it suitable for parts that need to handle stress and potential impacts.

3.Polypropylene: Lightweight and resistant to chemicals, it’s often used for parts that need flexibility and durability.

4.Nylon: Provides high strength and resistance to wear, but can be more expensive. It’s used where high load-bearing capacity is needed.

- Design Considerations

5.Ergonomics: Ensure that the design is user-friendly and easy to adjust. The holder should securely grip the device without obstructing the user’s view or causing distractions.

6.Vibration Damping: Car mounts should be designed to minimize vibrations that can affect the stability of the device. Rubber or silicone pads can be integrated to absorb vibrations.

7.Heat Resistance: Car interiors can get very hot, so the material should be able to withstand high temperatures without deforming.

8.Mounting Mechanism: The design should include a robust mechanism for attaching the mount to various surfaces, such as suction cups, adhesive pads, or vent clips.

- Manufacturing Techniques

9.Injection Molding: Commonly used for producing large volumes of plastic parts with precise dimensions. It’s ideal for producing consistent and durable parts.

10.3D Printing: Useful for prototyping and custom designs. It allows for rapid adjustments to the design and testing of fit and function.

11.Thermoforming: Involves heating plastic sheets and shaping them over molds. It’s used for parts with simple geometries and is cost-effective for lower production volumes.

- Quality Control

12.Testing: Parts should be tested for durability, impact resistance, and fit to ensure they meet quality standards.

13.Compliance: Ensure that materials and designs comply with automotive industry standards and regulations.

- Sustainability

14.Recycled Plastics: Consider using recycled materials to reduce environmental impact.

15.Design for Disassembly: Design parts so they can be easily disassembled for recycling at the end of their life cycle.

- Examples of Applications

16.Phone Holders: Parts that secure the phone in place and allow for easy adjustment of viewing angles.

17.GPS Mounts: Components that hold GPS devices securely while allowing for easy access and visibility.

18.Dashboard Clips: Clips and holders designed to attach to various parts of the dashboard or vents.

When developing plastic parts for car mount holders, balancing functionality, durability, and user convenience is crucial. Testing and iterative design can help refine the product to meet these needs effectively.

email : shine@haoshuntech.com

telephone: +8613560008062