plastic parts international work lamp led plastic parts

When it comes to plastic parts used in international work lamps, particularly those featuring LED technology, there are several important aspects to consider, including design, materials, manufacturing processes, and applications. Here’s a detailed overview:

- Design Considerations

1.Ergonomics: The design should be user-friendly, with grips or handles that make the lamp easy to carry and operate.

2.Heat Management: LEDs generate heat, so the design must incorporate features that allow for effective heat dissipation. This can include ventilation slots or the use of heat-conductive plastics.

3.Durability: The parts must be robust to withstand harsh environments, especially if used in construction or outdoor settings.

- Materials Used

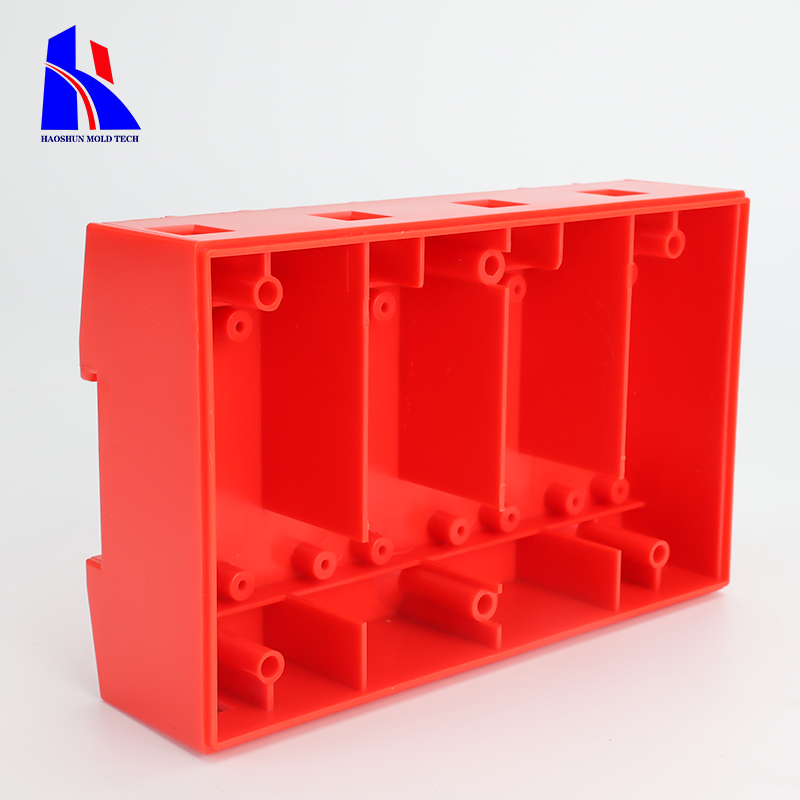

4.Polycarbonate (PC): Known for its high impact resistance and clarity, polycarbonate is often used for lens covers and housings.

5.Acrylonitrile Butadiene Styrene (ABS): This material provides good toughness and rigidity, making it suitable for structural components.

6.Polypropylene (PP): Lightweight and resistant to chemical corrosion, polypropylene is often used in lamp bases and casings.

7.Thermoplastic Elastomers (TPE): These materials can be used for grips or seals, providing flexibility and cushioning.

- Manufacturing Processes

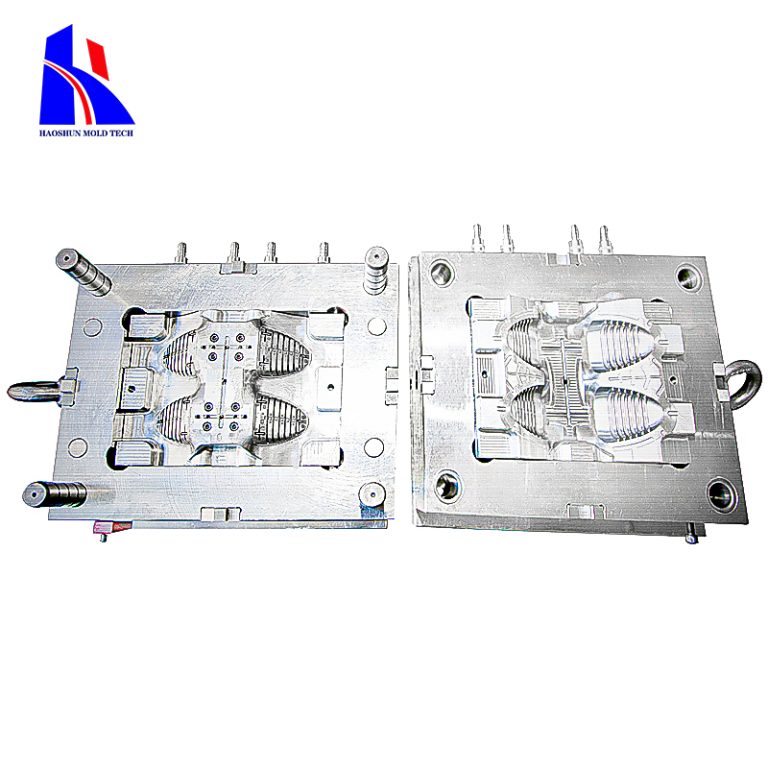

8.Injection Molding: This is the most common method for producing plastic parts. It allows for high precision and repeatability, making it ideal for mass production.

9.3D Printing: Increasingly used for prototyping and small runs, 3D printing offers design flexibility and quick turnaround.

10.Assembly: Components may be assembled using various methods, including snap fits, screws, or adhesives, depending on the design requirements.

- LED Technology

11.Light Output: LED chips are selected based on lumen output, color temperature, and energy efficiency.

12.Driver Circuitry: The circuit must be designed to convert AC to DC power and regulate the current to the LED to ensure longevity and performance.

13.Optics: Lens design is critical for directing light effectively. Fresnel lenses or reflectors may be integrated to enhance light distribution.

- Applications

14.Construction Sites: Portable work lamps are essential for providing illumination in areas without permanent lighting.

15.Emergency Services: LED work lamps are used in rescue operations, offering bright, reliable light.

16.Industrial Settings: Factories and warehouses often use work lamps for maintenance and safety inspections.

- Global Market Trends

17.Sustainability: There is a growing trend toward using recycled plastics and more sustainable manufacturing practices.

18.Smart Features: Integration with smart technologies for remote control or sensor-based operation is becoming more common.

19.Regulatory Standards: Compliance with international safety standards (like CE, UL, and RoHS) is crucial for market entry in different regions.

Conclusion

Plastic parts for international work lamps featuring LED technology are critical in various applications across industries. Their design and manufacturing must balance durability, functionality, and sustainability to meet the needs of users around the globe. If you are looking for suppliers or manufacturers, consider those with experience in producing high-quality, compliant products tailored to your specifications.

email : shine@haoshuntech.com

telephone: +8613560008062