plastic parts manufacturing

The Advantages of Plastic Parts Manufacturing

Plastic parts manufacturing has become an integral part of various industries, offering numerous advantages over traditional manufacturing methods. From automotive to electronics, plastic parts have revolutionized the way products are designed and produced. In this article, we will explore the advantages of plastic parts manufacturing and how it has transformed the manufacturing landscape.

One of the key advantages of plastic parts manufacturing is its cost-effectiveness. Compared to other materials like metal or glass, plastic is relatively inexpensive to produce. The raw materials used in plastic manufacturing are readily available and can be easily molded into complex shapes, reducing the need for additional processing steps. This not only saves time but also reduces production costs, making plastic parts an affordable option for manufacturers.

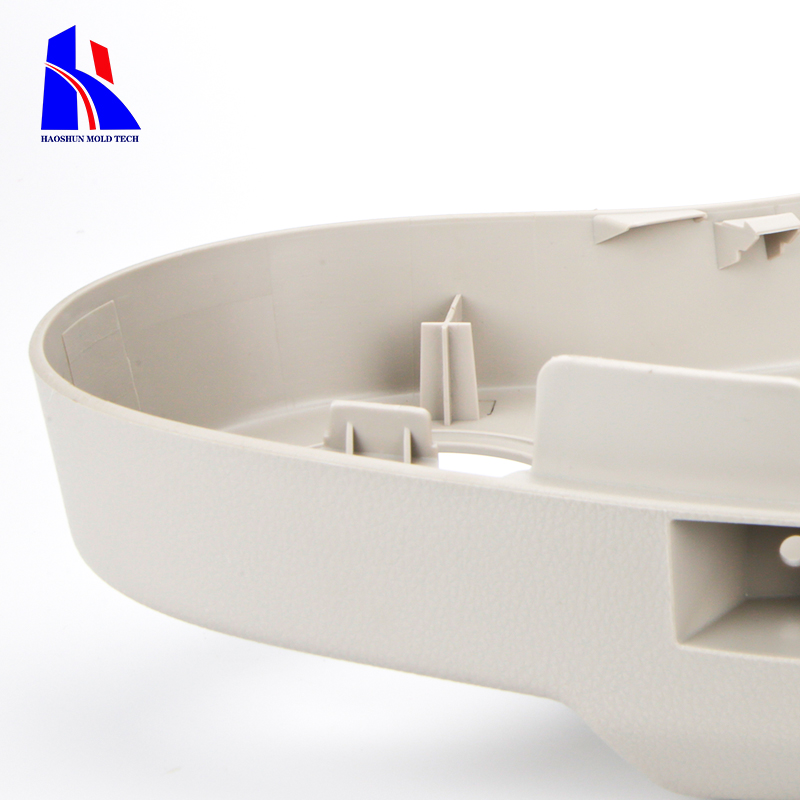

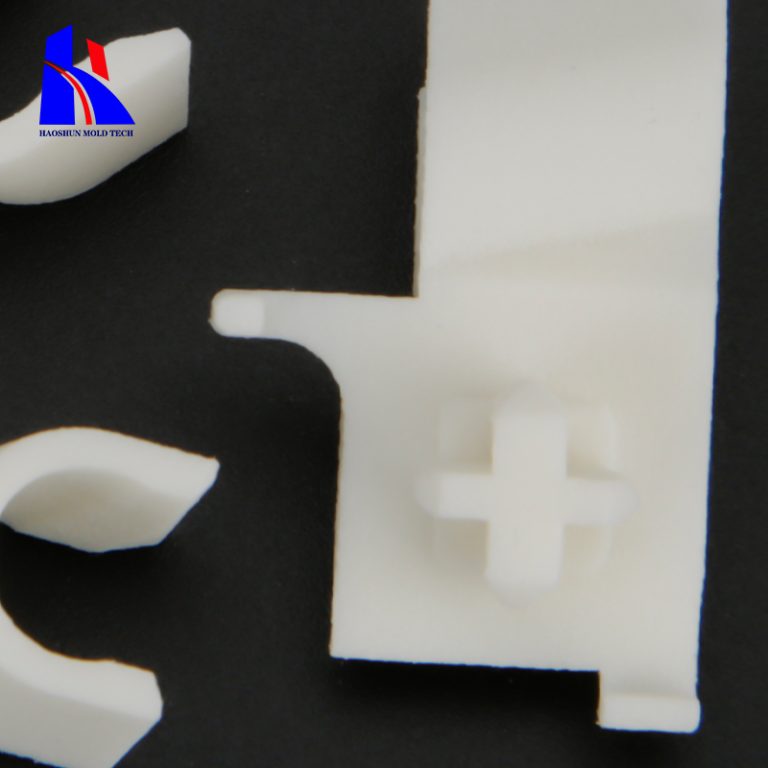

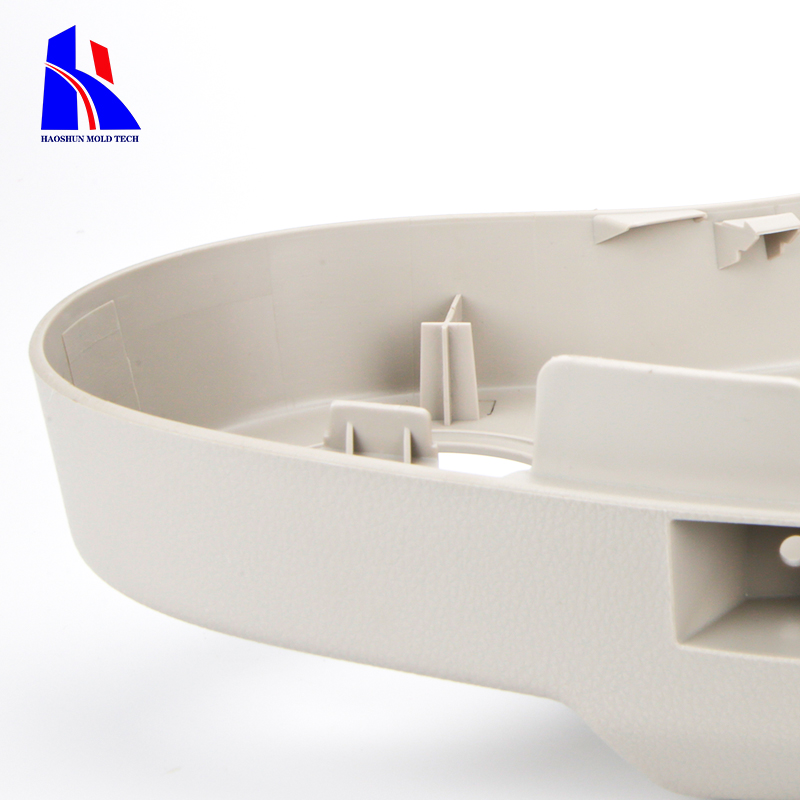

Another advantage of plastic parts manufacturing is its versatility. Plastic can be molded into virtually any shape or size, allowing for endless design possibilities. This flexibility is particularly beneficial in industries where intricate designs and complex geometries are required. Whether it’s a small component for a medical device or a large housing for an automotive part, plastic can be molded to meet the specific requirements of the product.

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

In addition to its versatility, plastic parts manufacturing offers excellent durability and strength. Modern plastics are engineered to withstand harsh conditions, making them suitable for a wide range of applications. Whether it’s exposure to extreme temperatures, chemicals, or physical stress, plastic parts can maintain their integrity and functionality. This durability ensures that products made from plastic parts have a longer lifespan, reducing the need for frequent replacements.

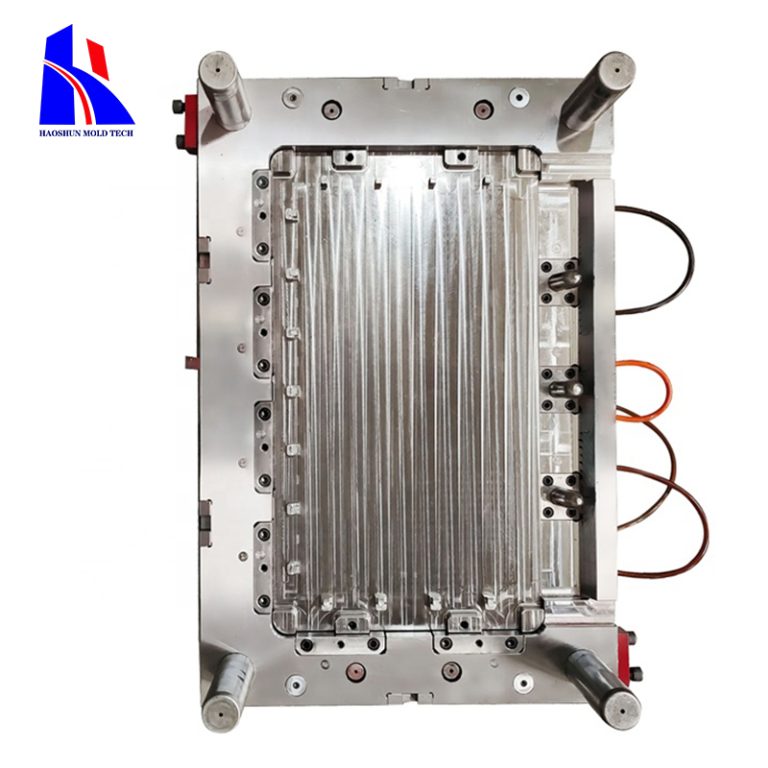

Furthermore, plastic parts manufacturing allows for efficient production processes. Injection molding, one of the most common methods used in plastic manufacturing, enables high-volume production with minimal waste. The molds used in injection molding can be reused multiple times, reducing the need for constant tooling changes. This not only saves time but also minimizes material waste, making plastic parts manufacturing an environmentally friendly option.

Plastic parts also offer excellent design flexibility. With the advancement of technology, manufacturers can incorporate various features into plastic parts, such as threads, hinges, and snap-fit connections. These design features eliminate the need for additional assembly steps, reducing production time and costs. Moreover, plastic parts can be easily modified or redesigned without the need for expensive tooling changes, allowing for quick iterations and improvements.

Additionally, plastic parts manufacturing offers excellent weight reduction capabilities. Compared to traditional materials like metal, plastic is significantly lighter, making it ideal for industries where weight is a critical factor. For example, in the automotive industry, using plastic parts can significantly reduce the overall weight of a vehicle, improving fuel efficiency and reducing emissions.

In conclusion, plastic parts manufacturing has revolutionized the manufacturing landscape, offering numerous advantages over traditional methods. From cost-effectiveness and versatility to durability and design flexibility, plastic parts have become an integral part of various industries. With its efficient production processes and weight reduction capabilities, plastic parts manufacturing continues to drive innovation and shape the future of manufacturing.