prototype plastic

Table of Contents

The Benefits of Using Prototype Plastic for Product Development

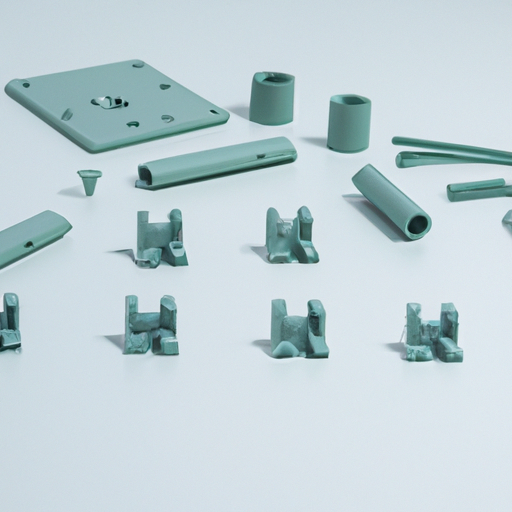

Prototype plastic is a valuable tool for product development, offering a range of benefits that can help to streamline the process. Prototype plastic is a cost-effective material that can be used to create a working model of a product before it is manufactured. This allows designers to test the product’s functionality and make any necessary changes before committing to a full production run.

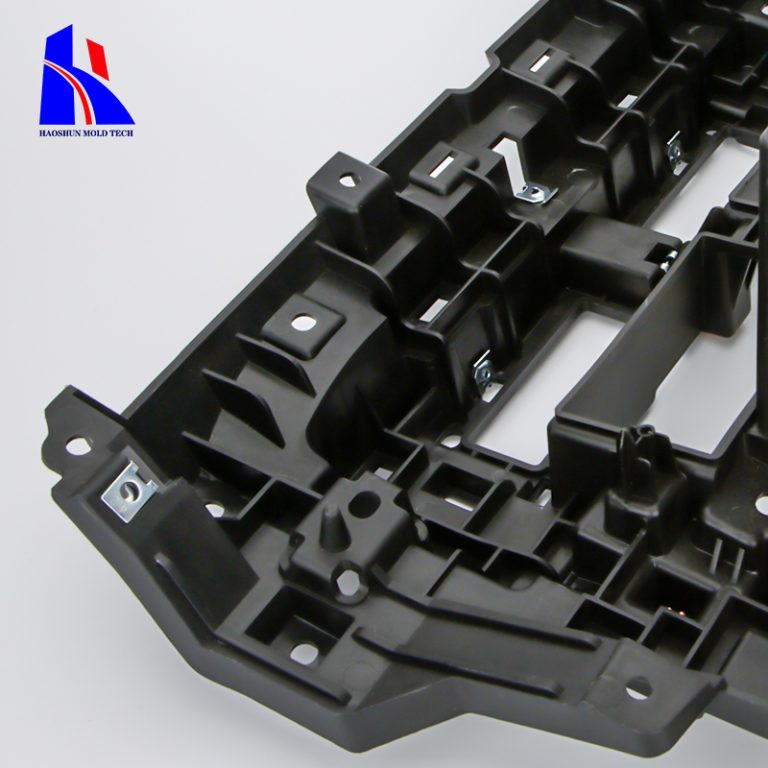

Prototype plastic is also a versatile material that can be used to create a wide range of products. It can be molded into complex shapes and is available in a variety of colors and textures. This makes it ideal for creating prototypes that closely resemble the final product.

Prototype plastic is also lightweight and durable, making it easy to transport and handle. This makes it ideal for testing the product in different environments and conditions. It is also resistant to heat and chemicals, making it suitable for use in a variety of industries.

Finally, prototype plastic is a cost-effective material that can be used to create a working model of a product before it is manufactured. This allows designers to test the product’s functionality and make any necessary changes before committing to a full production run. This can help to reduce costs and speed up the product development process.

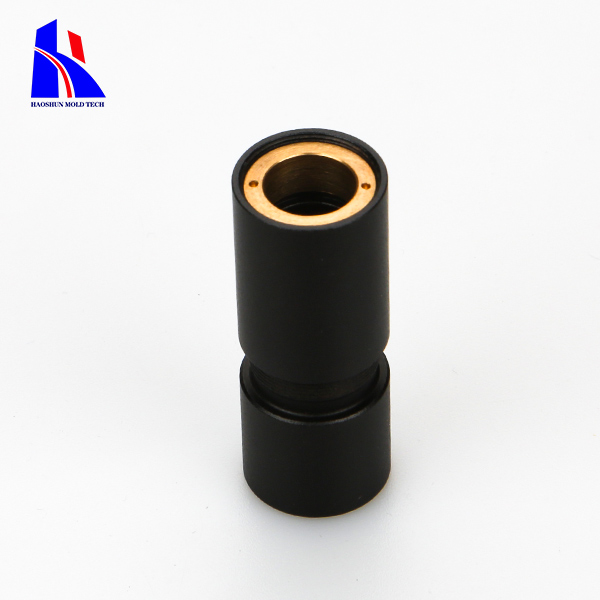

| Production Process | 3D Drawing-3D Max-File Conversion-Slice-Printing-Post Processing-Quality Inspection-Packaging-Shipment |

| Technology | SLA / SLS / MJF / FDM / DLP / SLM |

Overall, prototype plastic is a valuable tool for product development, offering a range of benefits that can help to streamline the process. It is a cost-effective, versatile, and durable material that can be used to create a working model of a product before it is manufactured. This can help to reduce costs and speed up the product development process.