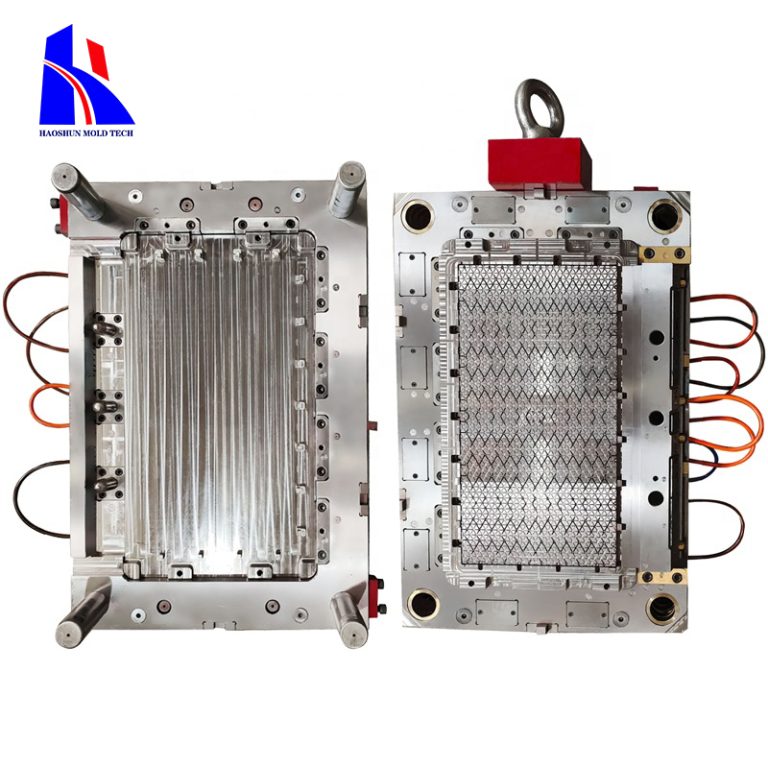

prototype plastic injection mould

Table of Contents

The Benefits of Using Prototype Plastic Injection Moulds for Product Development

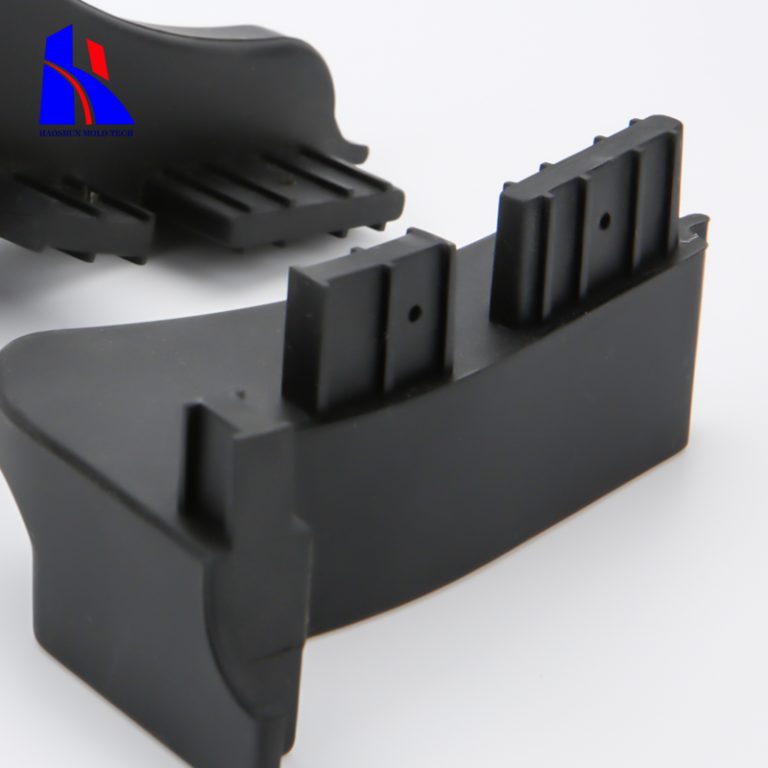

Prototype plastic injection moulds are a valuable tool for product development, offering a range of benefits that can help to streamline the process. Injection moulding is a manufacturing process that involves injecting molten plastic into a mould to create a desired shape. By using prototype plastic injection moulds, product developers can quickly and accurately create a range of parts and components for testing and evaluation.

| Quotation | According To Your Drawing |

| Drawing Formats | 2D(PDF/CAD) And 3D(STL/STEP) |

The use of prototype plastic injection moulds offers a number of advantages over other manufacturing processes. Firstly, the process is highly efficient, allowing for the rapid production of multiple parts in a short period of time. This makes it ideal for prototyping and testing, as it allows for quick iterations and modifications to be made. Secondly, the process is highly accurate, allowing for parts to be produced with tight tolerances and precise dimensions. This ensures that the parts produced are of a consistent quality and can be used for testing and evaluation.

In addition, prototype plastic injection moulds are cost-effective, as they can be used to produce a large number of parts in a short period of time. This reduces the cost of production, as the cost of the mould is spread across multiple parts. Furthermore, the process is also relatively simple, as it requires minimal setup and can be automated to reduce labour costs.

Overall, prototype plastic injection moulds offer a range of benefits that make them an ideal choice for product development. The process is highly efficient, accurate, cost-effective, and simple, allowing for the rapid production of parts for testing and evaluation. This makes it an invaluable tool for product developers, allowing them to quickly and accurately create a range of parts for testing and evaluation.

How to Choose the Right Prototype Plastic Injection Mould for Your Project