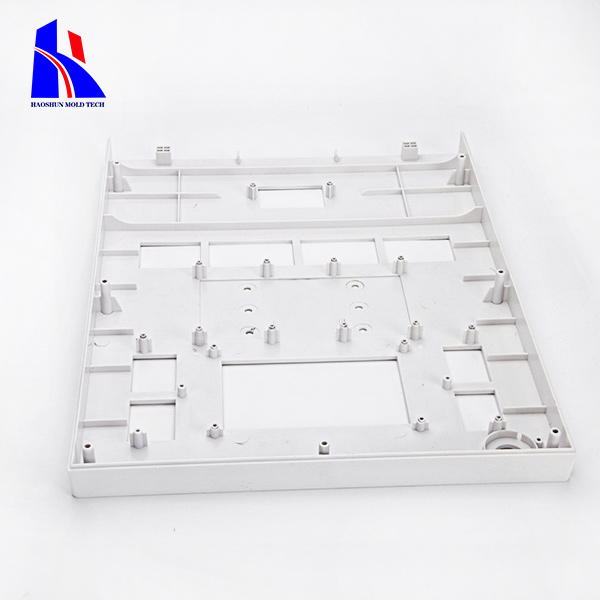

rapid injection molding

Benefits of Rapid Injection Molding in Manufacturing Processes

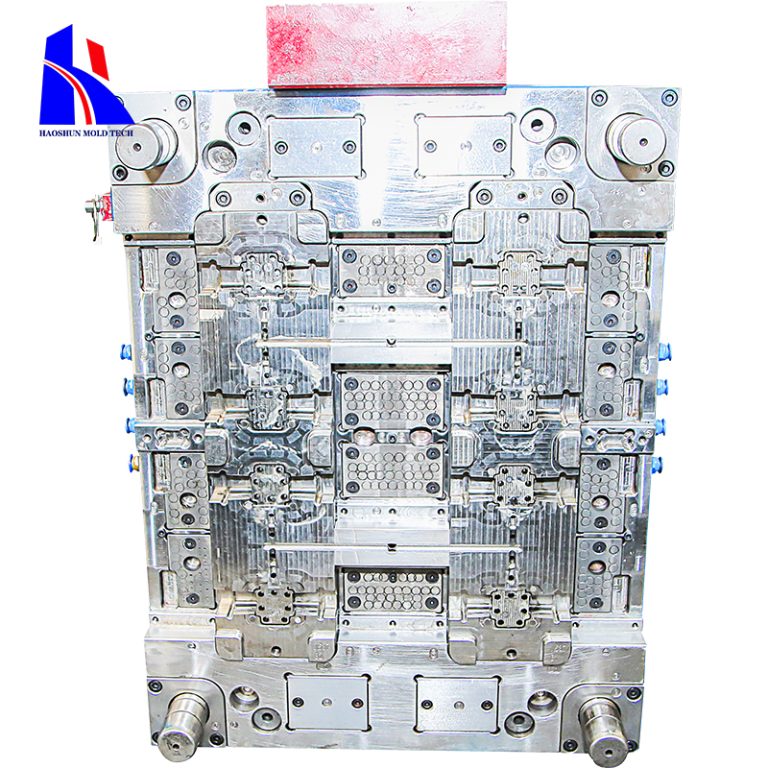

Rapid injection molding is a manufacturing process that has revolutionized the way products are designed and produced. This innovative technique allows for the quick and cost-effective production of high-quality plastic parts, making it an essential tool for businesses looking to stay competitive in today’s fast-paced market.

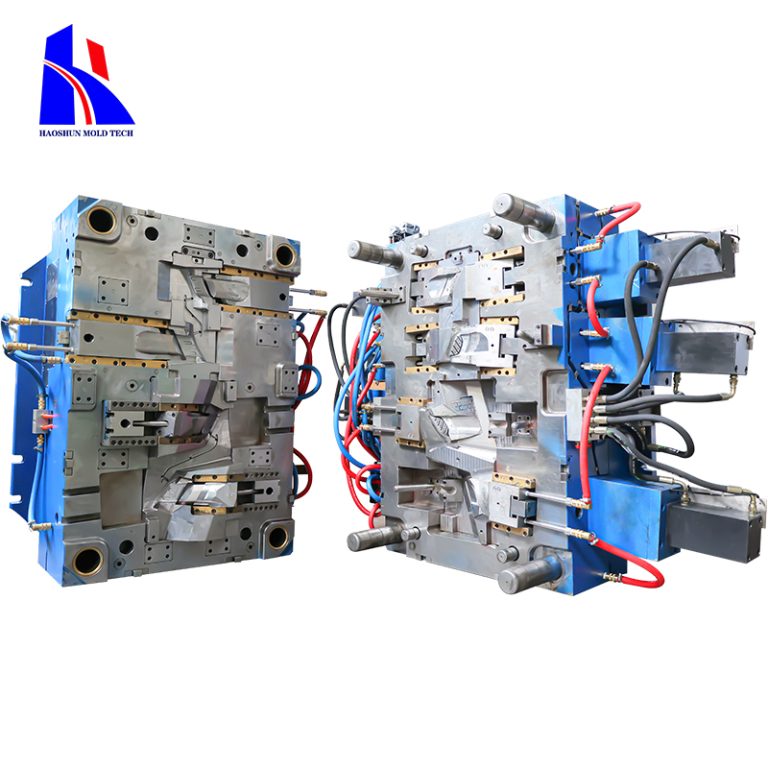

One of the key benefits of rapid injection molding is its speed. Traditional injection molding processes can take weeks or even months to complete, as molds need to be designed, fabricated, and tested before production can begin. In contrast, rapid injection molding can produce parts in a matter of days, allowing businesses to bring products to market much faster than ever before.

This speed is particularly advantageous for businesses operating in industries with short product life cycles, such as consumer electronics or fashion. By reducing the time it takes to go from design to production, rapid injection molding enables companies to quickly respond to changing market trends and customer demands, giving them a competitive edge in the marketplace.

In addition to speed, rapid injection molding also offers cost savings. Traditional injection molding processes require the creation of expensive molds, which can be a significant upfront investment for businesses. Rapid injection molding, on the other hand, uses 3D printing technology to create molds quickly and affordably, reducing the overall cost of production.

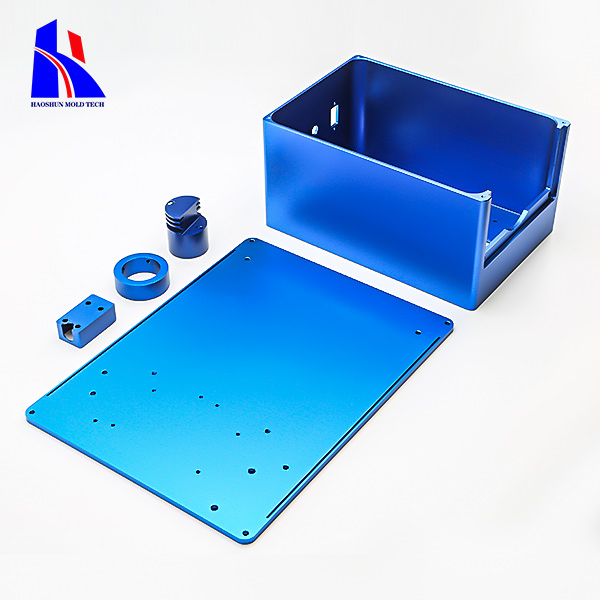

Furthermore, rapid injection molding allows for greater design flexibility. With traditional injection molding, making changes to a mold can be time-consuming and costly. In contrast, rapid injection molding allows for quick and easy modifications to be made to the mold, enabling businesses to iterate on their designs and test new ideas without incurring significant additional costs.

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

This flexibility is particularly valuable for businesses looking to innovate and differentiate themselves in the marketplace. By being able to quickly prototype and test new designs, companies can bring innovative products to market faster and more efficiently, helping them to stand out from the competition.

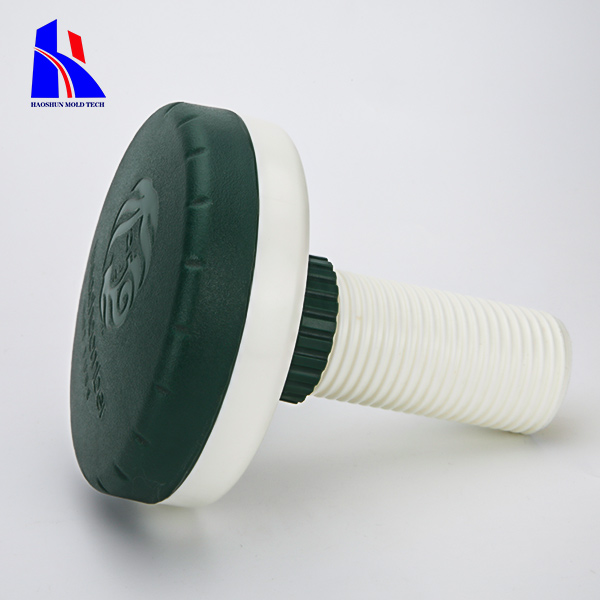

Another benefit of rapid injection molding is its ability to produce high-quality parts. The precision and accuracy of the injection molding process ensure that parts are consistently produced to the highest standards, with minimal defects or imperfections. This level of quality is essential for businesses looking to maintain a strong reputation for excellence and reliability.

Overall, rapid injection molding offers a range of benefits for businesses looking to streamline their manufacturing processes and bring products to market quickly and cost-effectively. By combining speed, cost savings, design flexibility, and high-quality production, rapid injection molding is a powerful tool for businesses looking to stay ahead in today’s competitive marketplace.