stainless steel cnc

Table of Contents

Exploring the Benefits of Stainless Steel CNC Machining

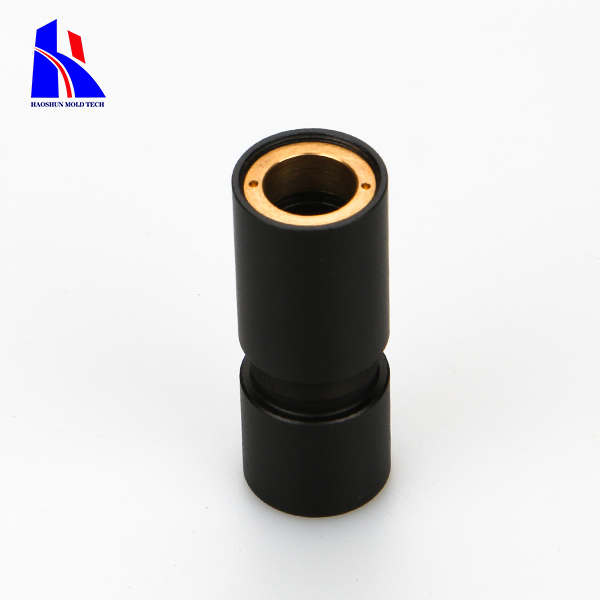

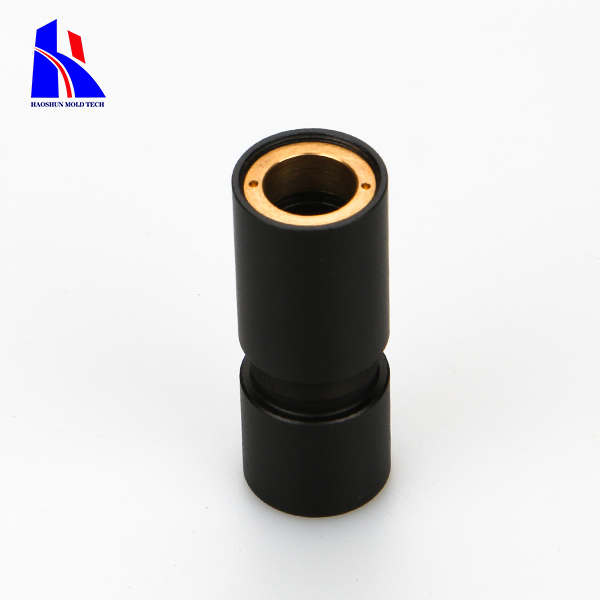

Stainless steel CNC machining is a process that has revolutionized the manufacturing industry. It is a highly precise and efficient way to create complex parts and components with a high degree of accuracy. With stainless steel CNC machining, you can create parts that are strong, durable, and corrosion-resistant.

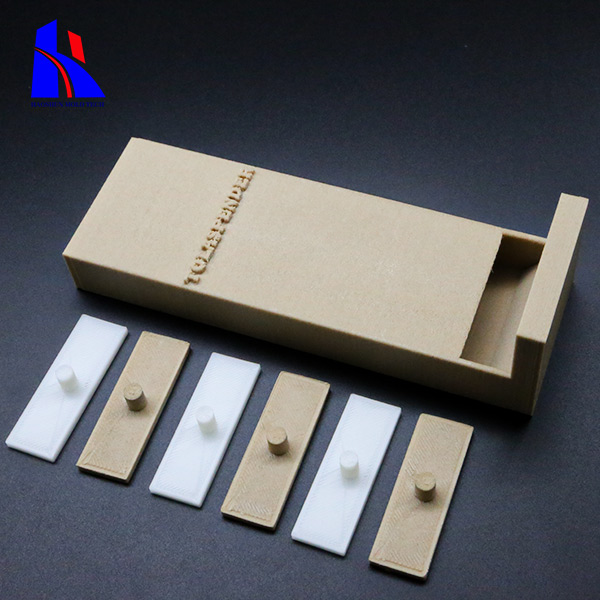

| Drawing Formats | 2D(PDF/CAD) And 3D(STP / STEP) |

| Materials | Aluminum / Stainless Steel / Steel / Brass / Copper / Plastic / Iron / Alloy / Zinc / Etc. Other Special Materials:Nylon/Titanium/Lucite/Etc. |

| Main Process | CNC Turning / Milling / Drilling / Bushing / Auto Lathe / Surface Treatment / Etc. |

The benefits of stainless steel CNC machining are numerous. For starters, it is a cost-effective way to produce parts and components. The process is highly automated, which means that it requires minimal human intervention. This reduces labor costs and increases efficiency. Additionally, stainless steel CNC machining is incredibly precise. It can produce parts with tight tolerances and intricate details. This makes it ideal for creating complex parts and components that require a high degree of accuracy.

Another benefit of stainless steel CNC machining is its durability. The parts and components created with this process are strong and resistant to corrosion. This makes them ideal for use in harsh environments and applications that require a high level of durability. Additionally, stainless steel CNC machining is incredibly versatile. It can be used to create parts and components of various shapes and sizes. This makes it ideal for a wide range of applications.

Finally, stainless steel CNC machining is incredibly efficient. The process is highly automated, which means that it requires minimal human intervention. This reduces labor costs and increases efficiency. Additionally, the process is incredibly fast. This means that parts and components can be created quickly and efficiently.

Overall, stainless steel CNC machining is an incredibly efficient and cost-effective way to create complex parts and components with a high degree of accuracy. It is strong, durable, and corrosion-resistant, making it ideal for use in harsh environments and applications that require a high level of durability. Additionally, it is incredibly versatile and efficient, making it ideal for a wide range of applications. If you’re looking for a reliable and cost-effective way to create complex parts and components, stainless steel CNC machining is the perfect solution.