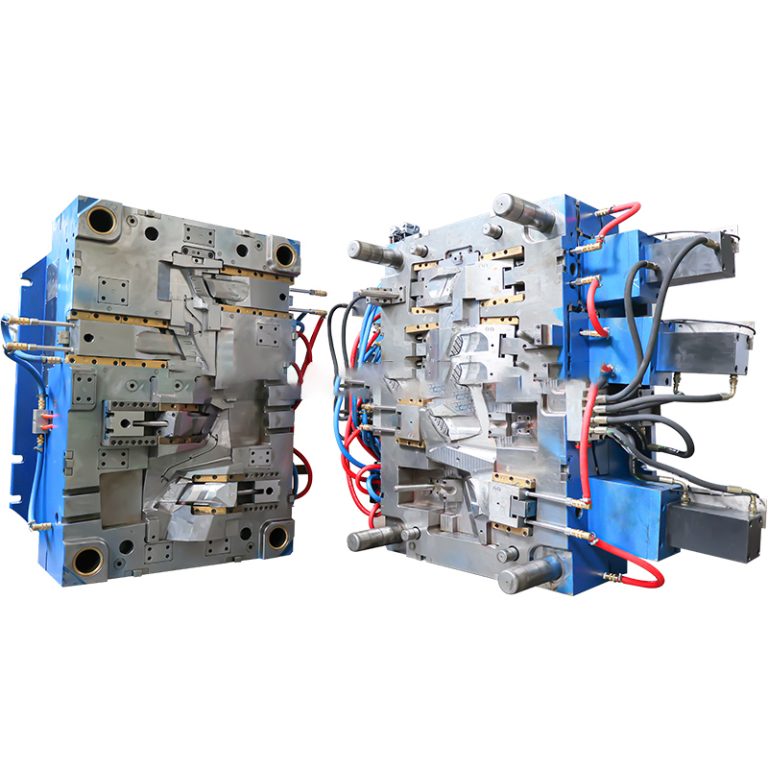

plastic prototype services low volume rapid prototype manufacturing

When it comes to plastic prototype services for low-volume rapid prototyping, there are several companies and services that specialize in providing these solutions. Here’s a breakdown of what these services typically offer: 1.Rapid Prototyping Technologies: Companies often utilize various rapid prototyping technologies such as 3D printing (FDM, SLA, SLS), CNC machining, or vacuum casting. Each…