two component plastic injection molding

Advantages of Two Component Plastic Injection Molding

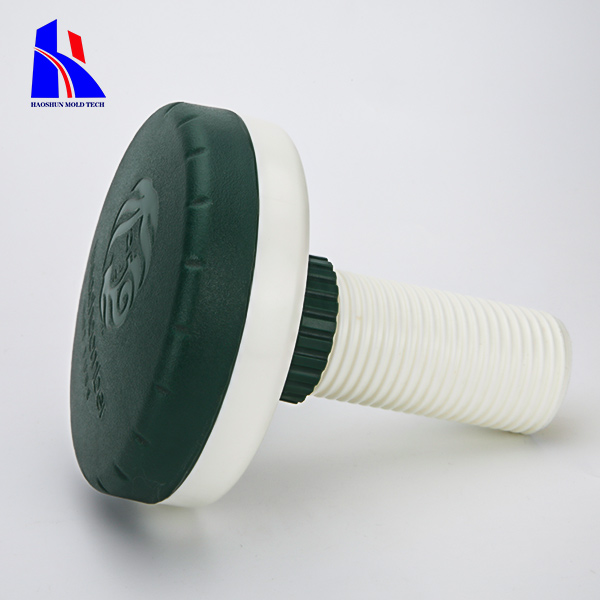

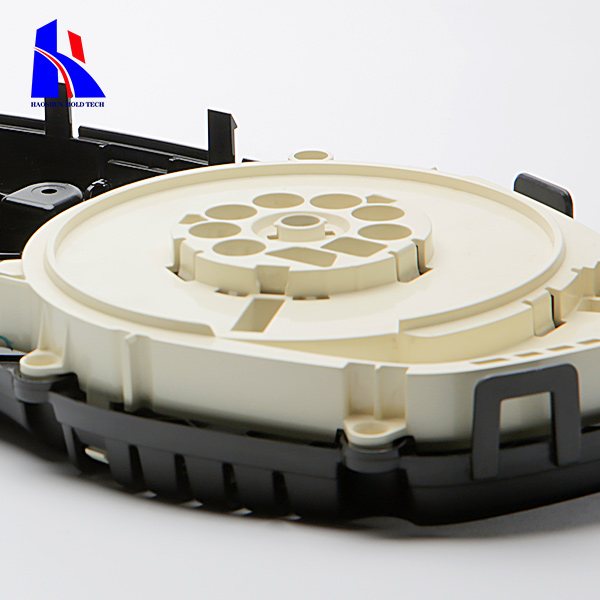

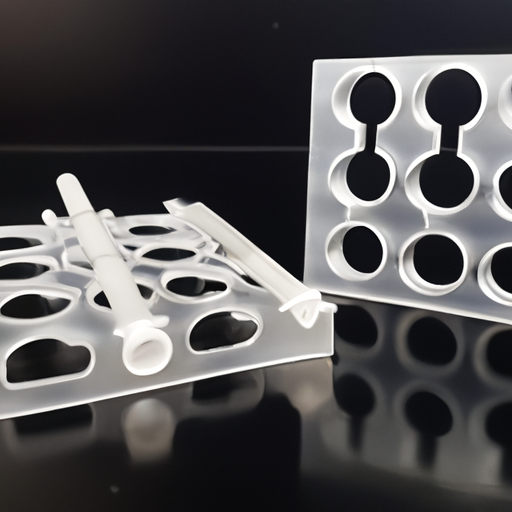

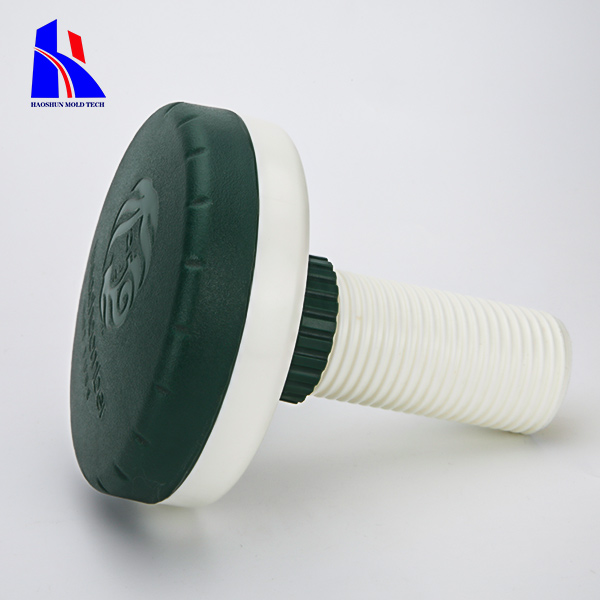

Two component plastic injection molding is a manufacturing process that involves injecting two different materials into a mold to create a single, integrated product. This process offers several advantages over traditional injection molding techniques, making it a popular choice for many industries.

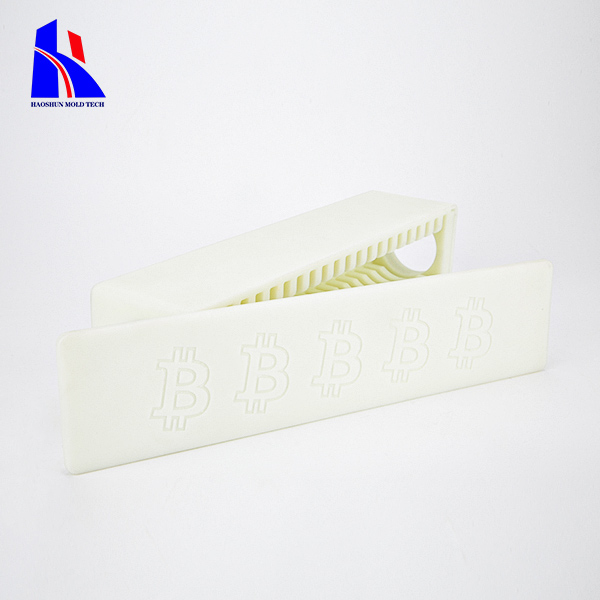

One of the main advantages of two component plastic injection molding is the ability to create complex and intricate designs. By using two different materials, manufacturers can achieve a wide range of colors, textures, and finishes in a single product. This opens up a world of possibilities for designers and allows them to create products that are visually appealing and unique.

Another advantage of two component plastic injection molding is the ability to combine materials with different properties. For example, a product may require a hard outer shell for durability, but a soft inner core for comfort. With two component molding, manufacturers can easily achieve this combination of properties in a single product. This is particularly useful in industries such as automotive, where products need to be both strong and comfortable.

Two component plastic injection molding also offers improved efficiency and cost-effectiveness. By combining two materials in a single mold, manufacturers can reduce the number of production steps and eliminate the need for additional assembly processes. This not only saves time but also reduces the risk of errors and defects. Additionally, the use of two component molding can result in lower material waste, as manufacturers can precisely control the amount of each material used.

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

Furthermore, two component plastic injection molding allows for improved product performance. By combining materials with different properties, manufacturers can create products that are stronger, more durable, and more resistant to wear and tear. This is particularly important in industries such as aerospace and medical, where products need to withstand extreme conditions and frequent use.

In addition to these advantages, two component plastic injection molding also offers environmental benefits. By reducing the number of production steps and material waste, manufacturers can minimize their carbon footprint and contribute to a more sustainable manufacturing process. This is becoming increasingly important as companies strive to meet environmental regulations and consumer demands for eco-friendly products.

Overall, two component plastic injection molding offers numerous advantages over traditional injection molding techniques. From the ability to create complex designs to the combination of materials with different properties, this process provides manufacturers with greater flexibility and efficiency. Additionally, the improved product performance and environmental benefits make it a preferred choice for many industries. As technology continues to advance, it is likely that two component plastic injection molding will become even more prevalent in the manufacturing world.