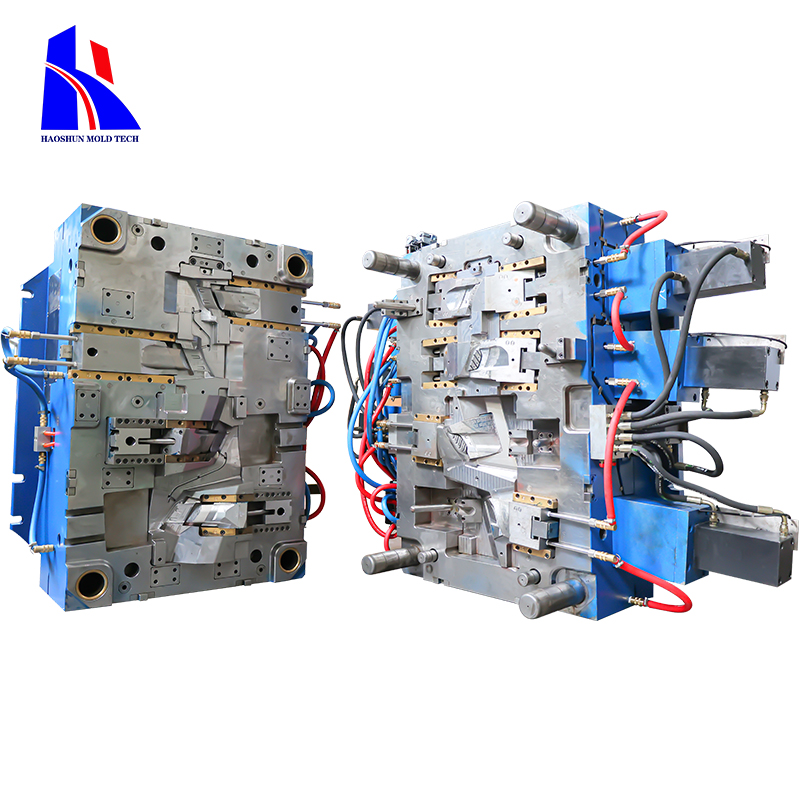

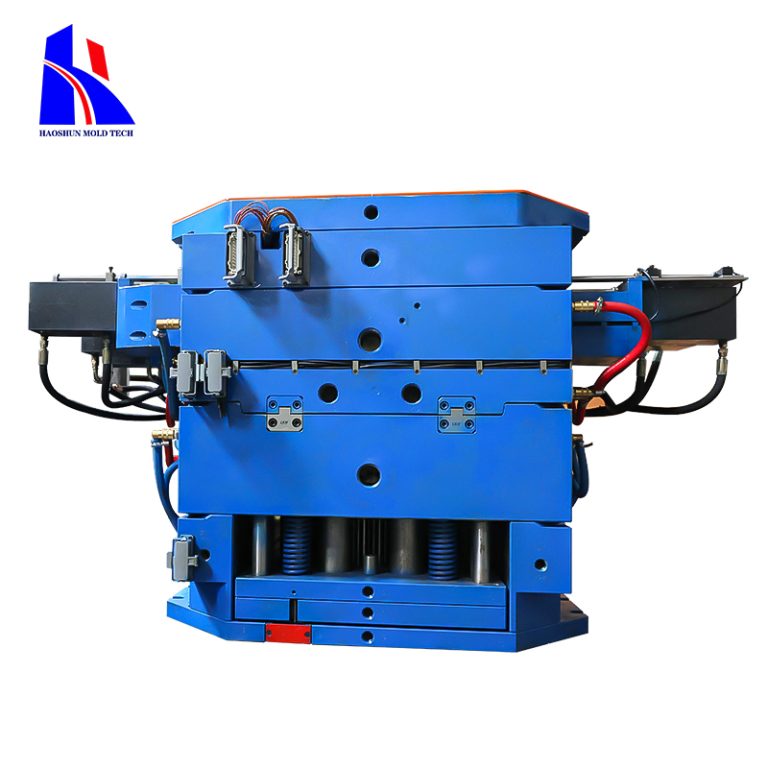

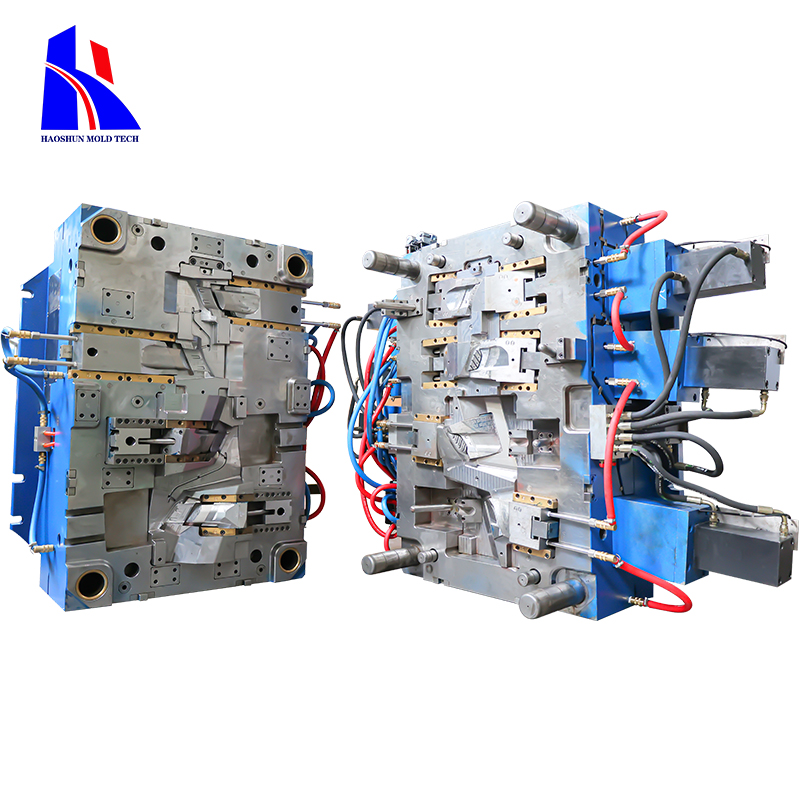

vacuum plastic mold maker

Table of Contents

Exploring the Benefits of Vacuum Plastic Mold Making for Manufacturers

Vacuum plastic mold making is a process that has been used by manufacturers for decades to create high-quality plastic parts and components. This process involves the use of a vacuum chamber to form a plastic part or component from a mold. The process is highly efficient and cost-effective, making it an attractive option for manufacturers looking to produce high-quality parts and components.

The primary benefit of vacuum plastic mold making is that it allows manufacturers to produce parts and components with a high degree of accuracy and precision. This is due to the fact that the vacuum chamber creates a vacuum environment that eliminates air bubbles and other imperfections that can occur during the molding process. This ensures that the parts and components produced are of the highest quality and are free from defects.

Another benefit of vacuum plastic mold making is that it is a relatively quick process. The vacuum chamber is able to quickly and accurately form the plastic part or component, allowing manufacturers to produce parts and components in a timely manner. This can be especially beneficial for manufacturers who need to produce parts and components in large quantities.

| Gate type | Pin-point Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, hot nozzles etc. |

| Equipment | CNC,EDM, Wire Cutting Machine, grinding ,drilling ,injection machine, |

In addition to being a quick and accurate process, vacuum plastic mold making is also a cost-effective option for manufacturers. The process requires minimal setup and maintenance costs, making it an attractive option for manufacturers who are looking to reduce their production costs.

Finally, vacuum plastic mold making is a safe process. The vacuum chamber eliminates the risk of fire or explosions, making it a safe option for manufacturers who are looking to produce parts and components in a safe and secure environment.

Overall, vacuum plastic mold making is an efficient and cost-effective process that offers numerous benefits to manufacturers. The process is quick, accurate, and safe, making it an attractive option for manufacturers looking to produce high-quality parts and components in a timely and cost-effective manner.